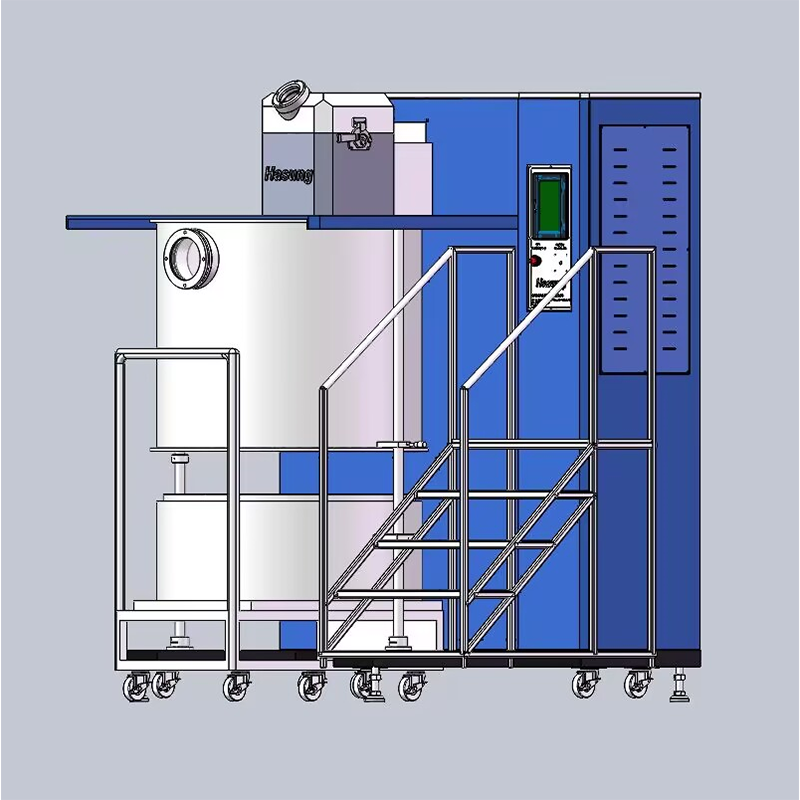

I-100 ye-mesh - i-400 mesh ye-Metal Powder Water Atomizer Machine

Iiparamitha zobuGcisa

| Umzekelo No. | HS-MGA5 | HS-MGA10 | HS-MGA30 | HS-MGA50 | HS-MGA100 |

| I-Voltage | 380V 3 Izigaba, 50/60Hz | ||||

| Ukunikezwa Amandla | 15KW | 30KW | 30KW/50KW | 60KW | |

| Umthamo (Au) | 5kg | 10kg | 30kg | 50kg | 100kg |

| Ubukhulu beTemp. | 1600°C/2200°C | ||||

| Ixesha lokunyibilika | 3-5 imiz. | 5-8 imiz. | 5-8 imiz. | 6-10 imiz. | 15-20 min. |

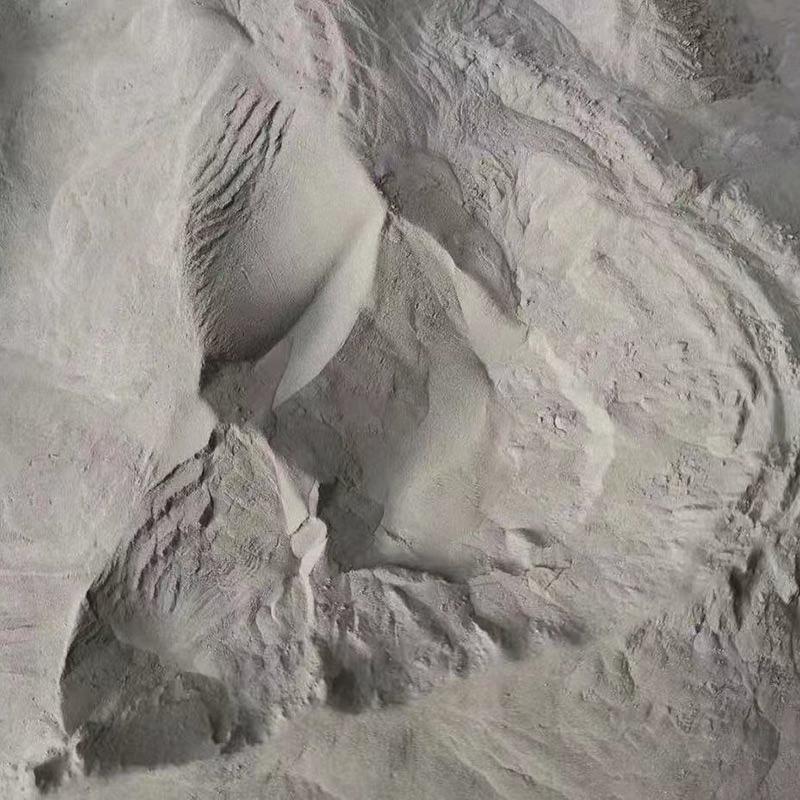

| Iinkozo zesuntswana (umnatha) | 200#-300#-400# | ||||

| Ukuchaneka kweTemp | ±1°C | ||||

| Impompo yokufunxa | Umgangatho ophezulu wempompo yokucoca idigri yevacuum | ||||

| Inkqubo ye-ultrasonic | Umgangatho ophezulu wenkqubo yokulawula inkqubo ye-ultrasonic | ||||

| Indlela yokusebenza | Ukusebenza okungundoqo okukodwa ukugqiba yonke inkqubo, inkqubo ye-POKA YOKE engenangqondo | ||||

| Inkqubo yokulawula | Mitsubishi PLC+Umntu-umatshini ujongano inkqubo ekrelekrele yolawulo | ||||

| Irhasi yangaphakathi | Nitrogen / Argon | ||||

| Uhlobo lokupholisa | Isibambisi samanzi (Ithengiswa ngokwahlukeneyo) | ||||

| Imilinganiselo | malunga. 3575*3500*4160mm | ||||

| Ubunzima | malunga. 2150kg | malunga. 3000kg | |||

IAtomization pulverizing method yinkqubo entsha ephuhliswe kwishishini lesinyithi somgubo kwiminyaka yakutshanje. Inoncedo lwenkqubo elula, itekhnoloji elula ukuyiqonda, imathiriyeli akulula ukuba i-oxidized, kunye nenqanaba eliphezulu lokuzenzekelayo.

1. Inkqubo ethile kukuba emva kokuba i-alloy (isinyithi) inyibilika kwaye icocwe kwi-furnace induction, ulwelo olutyhidiweyo lwetsimbi lugalelwa kwi-crucible yokugcinwa kobushushu kwaye lungena kwi-tube yesikhokelo kunye nombhobho. Ngeli xesha, i-melt flow ivalwe yi-high-pressure fluid flow (okanye ukuhamba kwegesi) I-atomized kunye ne-atomized powder yensimbi iqinisiwe kwaye ihlaliswe kwinqaba ye-atomization, ize iwele kwi-powder yokuqokelela itanki yokuqokelela kunye nokwahlula. Isetyenziswa kakhulu kwintsimi yokwenza umgubo wentsimbi ongeyoyoni njengomgubo wentsimbi, umgubo wobhedu, umgubo wentsimbi kunye nomgubo wealloyi. Itekhnoloji yokwenza iiseti ezipheleleyo zezixhobo zomgubo wentsimbi, izixhobo zomgubo wobhedu, izixhobo zomgubo wesilivere kunye nezixhobo zomgubo wealloyi ziya zikhula ngakumbi nangakumbi.

2. Ukusetyenziswa kunye nomgaqo-siseko wesixhobo sokucola i-atomization yamanzi, isixhobo sokucola i-atomization yamanzi sisixhobo esiyilelwe ukuhlangabezana nokuveliswa kwenkqubo yokucolwa kwe-atomization yamanzi phantsi kweemeko ze-atmospheric, kwaye sisixhobo sokuvelisa ubunzima obukhulu. Umgaqo osebenzayo wezixhobo zokucola i-atomization yamanzi ubhekiselele ekunyibilikeni kwesinyithi okanye ingxubevange yesinyithi phantsi kweemeko zomoya. Ngaphantsi kwemeko yokukhusela igesi, i-metal liquid igeleza kwi-tundish ye-thermal insulation kunye nombhobho wokuguqula, kwaye i-ultra-high-high pressure water ihamba nge-nozzle. Ulwelo lwetsimbi lwe-atomized kwaye luqhekeke kwinani elikhulu lamaconsi eentsimbi ezintle, kwaye amaconsi amahle enza amaqhekeza angaphantsi kwe-spherical okanye angaqhelekanga phantsi kwesenzo esidityanisiweyo soxinzelelo lomphezulu kunye nokupholisa ngokukhawuleza kwamanzi ngexesha lokuhamba ukufezekisa injongo yokugaya.

3. Izixhobo zokucoca i-atomization yamanzi zinezi mpawu zilandelayo: 1. Iyakwazi ukulungiselela ininzi yesinyithi kunye ne-alloy powder yayo, kwaye iindleko zokuvelisa ziphantsi. 2. I-powder subspherical okanye ipowder engaqhelekanga ingalungiswa. 3. Ngenxa yokuqina ngokukhawuleza kwaye akukho lucalucalulo, ezininzi i-alloy powders ezikhethekileyo zinokulungiswa. 4. Ngokulungelelanisa inkqubo efanelekileyo, ubukhulu bepowder particle bunokufikelela kuluhlu olufunekayo.

4. Ulwakhiwo lwezixhobo zokucofa i-atomization yamanzi Ulwakhiwo lwezixhobo zokucola i-atomizing yamanzi luquka la malungu alandelayo: ukunyibilika, inkqubo ye-tundish, inkqubo ye-atomization, inkqubo yokukhusela igesi engasebenziyo, inkqubo yoxinzelelo oluphezulu lwamanzi, ukuqokelelwa komgubo, ukuphelelwa ngamanzi emzimbeni kunye nenkqubo yokomisa, inkqubo yokuhlola, inkqubo yamanzi okupholisa, inkqubo yolawulo ye-PLC, inkqubo yeqonga, njl. njl. 1. Inkqubo yokunyibilika kunye ne-tundish: Enyanisweni, yinkqubo i-intermediate frequency induction melting furnace, ebandakanya: iqokobhe, icoil yokungeniswa, isixhobo sokulinganisa ubushushu, isixhobo somlilo esithambekisayo, i-tundish kunye nezinye iindawo: iqokobhe lisakhiwo sesakhelo, esiyikhabhoni Yenziwe ngentsimbi kunye nentsimbi engatyiwayo, i-coil induction ifakiwe. phakathi, kwaye i-crucible ifakwe kwi-coil induction, enokuthi inyibilike kwaye igalelwe. I-tundish ifakwe kwi-nozzle system, isetyenziselwa ukugcina ulwelo olunyibilikisiweyo lwesinyithi, kwaye inomsebenzi wokugcina ubushushu. Incinci kune-crucible ye-smelting system. Isithando somlilo se-tundish sinenkqubo yayo yokufudumeza kunye nenkqubo yokulinganisa ubushushu. Inkqubo yokufudumala yesithando somlilo sineendlela ezimbini: ukufudumala ukufudumala kunye nokufudumala kwe-induction. Ubushushu bobushushu bokumelana nobushushu bunokufikelela kwi-1000 ℃, kwaye iqondo lobushushu le-induction lingafikelela kwi-1200 ℃ okanye ngaphezulu, kodwa izinto ezikroliweyo kufuneka zikhethwe ngokufanelekileyo. 2. Inkqubo ye-atomization: Inkqubo ye-atomization iqukethe imibhobho, imibhobho yamanzi yoxinzelelo oluphezulu, iivalve, njl. 3. Inkqubo yokukhusela igesi engasebenziyo: kwinkqubo yokucoca, ukwenzela ukunciphisa i-oxidation yesinyithi kunye ne-alloys kunye nokunciphisa umxholo we-oxygen. yomgubo, umlinganiselo othile werhasi ye-inert idla ngokungeniswa kwinqaba ye-atomization yokukhusela umoya. 4. Isixokelelwano samanzi esine-Ultra-high-high-pressure: Le nkqubo sisixhobo esibonelela ngamanzi anoxinzelelo oluphezulu lwe-atomizing nozzles. Iqulethe iimpompo zamanzi ezinoxinzelelo oluphezulu, iitanki zamanzi, iivalvu, imibhobho yoxinzelelo oluphezulu kunye neebhasi. 5. Inkqubo yokupholisa: Isixhobo sonke sixhotyiswe ngamanzi okupholisa, kwaye inkqubo yokupholisa ibalulekile. Ukushisa kwamanzi okupholisa kuya kubonakaliswa kwisixhobo sesibini ukuqinisekisa ukusebenza ngokukhuselekileyo kwesixhobo. 6. Inkqubo yokulawula: Inkqubo yokulawula iziko lokulawula ukusebenza kwesixhobo. Yonke imisebenzi kunye nedatha ehambelanayo idluliselwa kwi-PLC yenkqubo, kwaye iziphumo zicutshungulwa, zigcinwe kwaye ziboniswe ngokusebenza.

I-R&D kunye nokuveliswa kwezixhobo zobuchwephesha ukulungiselela izixhobo ezintsha zomgubo, ukubonelela ngezisombululo zothotho lweengcali zokuvelisa izixhobo ezintsha zomgubo, itekhnoloji yokulungiselela umgubo ongqukuva onamalungelo obunini obukrelekrele obuzimeleyo / itekhnoloji yokulungiselela umgubo osicaba / itekhnoloji yokulungiselela umgubo / iflake. iteknoloji yokulungiselela umgubo, kunye neteknoloji yokulungiselela i-ultrafine/nano powder, iteknoloji yokulungisa i-chemical purity purity.

Inkqubo yokwenza iMetal Powder ngeAtomization yamanzi Isixhobo sokuPulverizing

Inkqubo yokwenza umgubo wesinyithi ngamanzi atomization pulverizing izixhobo inembali ende. Kumaxesha amandulo, abantu babegalela intsimbi etyhidiweyo emanzini ukuze igqabhuke ibe ngamasuntswana esinyithi, awayesetyenziselwa ukwenza intsimbi; kude kube ngoku, kusekho abantu abagalela ilothe enyibilikisiweyo ngokuthe ngqo emanzini ukwenza iipellets zelothe. . Ukusebenzisa indlela ye-atomization yamanzi ukwenza i-coarse alloy powder, umgaqo wenkqubo ufana nolulwelo olukhankanywe ngasentla lwamanzi oluqhekezayo lwesinyithi, kodwa ukusebenza kakuhle kwe-pulverization kuye kwaphuculwa kakhulu.

Isixhobo sokucola i-atomization yamanzi senza umgubo wealloyi orhabaxa. Okokuqala, igolide erhabaxa inyibilikiswa ezikweni. I-liquid yegolide encibilikisiweyo kufuneka igqitywe ngama-degrees angama-50, ize igalelwe kwi-tundish. Qalisa impompo yamanzi yoxinzelelo oluphezulu phambi kokuba ulwelo lwegolide lutofwe, kwaye uvumele isixhobo soxinzelelo oluphezulu lwe-atomization yamanzi siqale i-workpiece. Ulwelo lwegolide kwi-tundish ludlula kumqadi kwaye lungene kwi-atomizer ngombhobho ovuzayo osemazantsi e-tundish. IAtomizer sisixhobo esiphambili sokwenza umgubo orhabaxa wealloy yegolide ngoxinzelelo oluphezulu lwenkungu yamanzi. Umgangatho we-atomizer uhambelana nokusebenza kakuhle komgubo wesinyithi. Ngaphantsi kwesenzo samanzi anoxinzelelo oluphezulu olusuka kwiatomizer, ulwelo lwegolide luhlala luqhekeka lube ngamathontsi acolekileyo, awela kulwelo olupholisayo kwisixhobo, kwaye ulwelo luqina ngokukhawuleza lube ngumgubo wealloyi. Kwinkqubo yendabuko yokwenza i-metal powder nge-high-pressure water atomization, i-powder yensimbi ingaqokelelwa ngokuqhubekayo, kodwa kukho imeko yokuba i-powder encinci yensimbi ilahlekile kunye namanzi e-atomizing. Kwinkqubo yokwenza i-alloy powder nge-high-pressure ye-atomization yamanzi, imveliso ye-atomized igxininiswe kwisixhobo se-atomization, emva kwemvula, i-filtration, (ukuba kuyimfuneko, inokomiswa, ngokuqhelekileyo ithunyelwe ngokuthe ngqo kwinkqubo elandelayo.), ukufumana i-alloy powder ecocekileyo, akukho lahleko ye-alloy powder kuyo yonke inkqubo.

Iseti epheleleyo yezixhobo zokucofa iatomization yamanzi Isixhobo sokwenza umgubo wealloyi siquka ezi nxalenye zilandelayo:

Indawo yokunyibilikisa:isithando somlilo esinyibilikisayo esinesantya esiphakathi okanye isithando somlilo esinesantya esiphezulu sesinyithi sinokukhethwa. Umthamo wesithando somlilo unqunywe ngokuhambelana nomthamo wokucutshungulwa komgubo wensimbi, kunye nesithando somlilo esingama-50 kg okanye i-20 kg yesithando somlilo singakhethwa.

Inxalenye yeAtomization:Izixhobo ezikule nxalenye zizixhobo ezingezizo eziqhelekileyo, ezifanele ziyilwe kwaye zilungiswe ngokwemiqathango yesayithi yomenzi. Kukho ubukhulu becala i-tundishes: xa i-tundish iveliswa ebusika, kufuneka ifakwe ngaphambili; I-atomizer: I-atomizer iya kuvela kuxinzelelo oluphezulu Uxinzelelo lwamanzi oluphezulu lwempompo luchaphazela ulwelo lwegolide olusuka kwi-tundish ngesantya esimiselweyo kunye ne-engile, ukuwaphula abe ngamathontsi esinyithi. Ngaphantsi koxinzelelo lwempompo yamanzi efanayo, isixa somgubo wesinyithi ococekileyo emva kwe-atomization sinxulumene nokusebenza kakuhle kwe-atomizer; i-atomization cylinder: yindawo apho i-alloy powder i-atomized, icolile, ipholile kwaye iqokelelwa. Ukuze kuthintelwe i-ultra-fine alloy powder kwi-alloy powder efunyenweyo ukuba ingalahleki ngamanzi, kufuneka ishiywe ixesha elithile emva kwe-atomization, kwaye emva koko ifakwe kwibhokisi yokuqokelela umgubo.

Inxalenye yasemva kokulungiswa:ibhokisi yokuqokelela umgubo: isetyenziselwa ukuqokelela umgubo we-atomized alloy kunye nokwahlula kunye nokususa amanzi angaphezulu; isithando somlilo: yomisa i-alloy powder emanzi ngamanzi; umatshini wokuhlola: hluza i-alloy powder, i-out-of-specification coarser alloy powders inokuphinda inyibilike kwaye i-atomized njengempahla yokubuyisela.

Itekhnoloji yeVacuum yeAtomization yoMoya kunye nokuSetyenziswa kwayo

I-powder elungiselelwe yi-vacuum air atomization ineenzuzo zokucoceka okuphezulu, umxholo ophantsi we-oksijeni kunye nobukhulu be-particle powder. Emva kweminyaka eqhubekayo yokwenziwa kwezinto ezintsha kunye nokuphuculwa, itekhnoloji ye-vacuum ye-atomization ye-atomization yomoya iye yaphuhliswa yaba yindlela ephambili yokuvelisa i-high-performance metal kunye ne-alloy powders, kwaye iye yaba yinto ehamba phambili yokuxhasa kunye nokukhuthaza uphando lwezixhobo ezintsha kunye nophuhliso lobuchwepheshe obutsha. Umhleli wazisa umgaqo, inkqubo kunye nezixhobo zokugaya umgubo we-vacuum air atomization, kwaye wahlalutya iintlobo kunye nokusetyenziswa komgubo olungiselelwe yi-vacuum air atomization.

Indlela ye-atomization yindlela yokulungisa umgubo apho ulwelo oluhamba ngokukhawuleza (i-atomizing medium) luchaphazela okanye luqhekeza isinyithi okanye ulwelo lwe-alloy lube ngamathontsi acolekileyo, athi ke adityaniswe abe ngumgubo oqinileyo. I-atomized powder particles ayinayo kuphela i-chemical composition efana ne-homogeneous efana ne-alloy etyhidiweyo etyhidiweyo, kodwa nangenxa yokuqiniswa ngokukhawuleza kuphucula i-crystalline structure kunye nokuphelisa i-macrosegregation yesigaba sesibini. I-atomization medium esetyenziswa ngokuqhelekileyo ngamanzi okanye i-ultrasonic, ebizwa ngokuba yi-atomization yamanzi kunye ne-gas atomization ngokufanelekileyo. Iipowder zetsimbi ezilungiselelwe nge-atomization yamanzi zinesivuno esiphezulu kunye nemveliso yezoqoqosho, kwaye izinga lokupholisa likhawuleza, kodwa i-powders inomxholo ophezulu we-oksijeni kunye ne-morphology engaqhelekanga, ngokuqhelekileyo i-flakes. I-powder elungiselelwe iteknoloji ye-atomization ye-ultrasonic inobungakanani obuncinci be-particle, i-sphericity ephezulu kunye nomxholo ophantsi we-oksijeni, kwaye ibe yindlela ephambili yokuvelisa i-high-performance spherical metal and alloy powders.

I-vacuum yokunyibilikisa i-atomization yegesi ephezulu yoxinzelelo lwe-atomization yetekhnoloji yokucoca idibanisa itekhnoloji yevacuum ephezulu, itekhnoloji yokunyibilikisa yobushushu obuphezulu, uxinzelelo oluphezulu kunye nobuchwepheshe berhasi enesantya esiphezulu, kwaye iveliswa ukuhlangabezana neemfuno zophuhliso lwesinyithi somgubo, ngakumbi ukuveliswa komgangatho ophezulu. iialloyi zomgangatho eziqulethe izinto ezisebenzayo umgubo. Itekhnoloji yokucoca itekhnoloji ye-Ultrasonic / yegesi yitekhnoloji entsha yokuqinisa ngokukhawuleza. Ngenxa yezinga eliphezulu lokupholisa, umgubo uneempawu zokucokisa iinkozo, ukubunjwa okufanayo kunye ne-solubility ephezulu eqinileyo.

Ukongeza kwezi zibonelelo zingentla, i-powder yensimbi eveliswa yi-vacuum smelting high-pressure gas atomization ineempawu ezintathu ezilandelayo: umgubo ococekileyo, umxholo ophantsi we-oksijeni; isivuno esiphezulu somgubo ocolekileyo; imbonakalo ephezulu sphericity. Izinto zokwakha okanye ezisebenzayo ezenziwe kulo mgubo zineenzuzo ezininzi kwizinto eziqhelekileyo ngokwezinto eziphathekayo kunye neekhemikhali. Umgubo ophuhlisiwe uquka umgubo we-superalloy, umgubo wokutshiza we-thermal, umgubo wealloyi wobhedu kunye nomgubo wentsimbi engatyiwa.

1 Inkqubo yokugaya i-atomization yomoya kunye nezixhobo

1.1 Inkqubo yokugaya i-atomization yomoya we-atomization yomoya

Indlela yokucoca iatomization yomoya luhlobo olutsha lwenkqubo ephuhliswe kwishishini lokwenziwa komgubo wesinyithi kwiminyaka yakutshanje. Ineengenelo zokungabi lula kwe-oxidation yezinto, ukucinywa ngokukhawuleza komgubo wesinyithi, kunye nenqanaba eliphezulu lokuzisebenzela. Inkqubo ethile kukuba emva kokuba i-alloy (isinyithi) inyibilika kwaye isulungekiswe kwiziko lokungeniswa, ulwelo lwesinyithi olutyhidiweyo lugalelwa kwi-thermal insulation slump, kwaye lungene kumbhobho wesikhokelo kunye nombhobho, kwaye ukuhamba kwenyibilika ku-atomized yi-high- ukuhamba kwegesi yoxinzelelo. I-atomized metal powder iyaqina kwaye ihlale kwi-atomization tower, kwaye iwela kwitanki yokuqokelela umgubo.

Izixhobo ze-atomizing, i-atomizing ultrasonic kunye nokuhamba kolwelo lwesinyithi yimiba emithathu esisiseko yenkqubo ye-atomization yegesi. Kwizixhobo ze-atomization, i-ultrasonic i-atomizing injected ikhawuleza kwaye idibanise ne-injected metal liquid flow flow ukwenza indawo yokuhamba. Kulo mmandla wokuhamba, ukuhamba kwesinyithi esinyibilikisiweyo kuphukile, kupholile kwaye kuqiniswe, ngaloo ndlela ufumana umgubo oneempawu ezithile. Iiparamitha zezixhobo ze-atomization zibandakanya isakhiwo se-nozzle, isakhiwo se-catheter, indawo ye-catheter, njl., igesi ye-atomization kunye neeparitha zenkqubo yayo ibandakanya iipropati ze-ultrasonic, uxinzelelo lwe-air inlet, i-air velocity, njl. iipropathi, ukushisa okukhulu, ukugeleza kwamanzi, njl njl. I-atomization ye-Ultrasonic ifezekisa injongo yokulungelelanisa ubungakanani be-powder particle, ukusabalalisa ubungakanani be-particle kunye ne-microstructure ngokulungelelanisa iiparitha ezahlukeneyo kunye nazo. ulungelelaniso.

1.2 Isixhobo sokucola i-atomization yomoya

Isixhobo sangoku se-vacuum atomization pulverizing sibandakanya izixhobo zangaphandle kunye nezixhobo zasekhaya. Izixhobo eziveliswe phesheya zinozinzo oluphezulu kunye nokuchaneka kokulawula okuphezulu, kodwa iindleko zezixhobo ziphezulu, kwaye iindleko zokugcina kunye nokulungiswa ziphezulu. Iindleko zezixhobo zasekhaya ziphantsi, iindleko zokuzigcina ziphantsi, kwaye ukugcinwa kulula. Nangona kunjalo, abavelisi bezixhobo zasekhaya ngokubanzi abanalwazi lwetekhnoloji ephambili yezixhobo ezinje nge-atomizing nozzles kunye neenkqubo ze-atomization. Okwangoku, amaziko ophando angaphandle afanelekileyo kunye namashishini emveliso agcina itekhnoloji iyimfihlo ngokungqongqo, kwaye imilinganiselo yenkqubo ethile kunye neshishini ayinakufunyanwa kuncwadi olufanelekileyo kunye namalungelo awodwa omenzi wechiza. Oku kwenza ukuba isivuno sepowder ephezulu siphantsi kakhulu ukuba sibe noqoqosho, nto leyo esona sizathu sokuba ilizwe lam lingakwazi ukuvelisa imveliso yepowder ephezulu nangona kukho ezininzi i-aerosol powder production kunye neeyunithi zophando lwezenzululwazi.

Ubume besixhobo sokucoca i-atomization ye-ultrasonic siquka ezi nxalenye zilandelayo: i-intermediate frequency induction melting furnace, isithando somlilo, inkqubo ye-atomization, itanki ye-atomization, inkqubo yokuqokelela uthuli, inkqubo yokubonelela nge-ultrasonic, inkqubo yokupholisa amanzi, inkqubo yokulawula, njl.

Okwangoku, uphando olwahlukeneyo malunga ne-aerosolization lugxile ikakhulu kwimiba emibini. Ngakolunye uhlangothi, iiparameters zesakhiwo se-nozzle kunye neempawu zokuhamba kwejethi zifundwa. Injongo kukufumana ubudlelwane phakathi kwebala lokuhamba komoya kunye nesakhiwo se-nozzle, ukwenzela ukuba i-ultrasonic ifikelele kwisantya kwi-nozzle outlet ngelixa i-ultrasonic flow rate incinci, kwaye ibonelela ngesiseko sethiyori yokuyila kunye nokucubungula umbhobho. Ngakolunye uhlangothi, ubudlelwane phakathi kweeparamitha zenkqubo ye-atomization kunye neepropati ze powder zafundwa. Ijolise ekufundeni umphumo weeparameters zenkqubo ye-atomization kwiipropati ze-powder kunye nokusebenza kakuhle kwe-atomization kwisiseko esicacileyo somlomo wokuphucula kunye nokukhokela ukuveliswa kwe powder. Ngelizwi, ukuphucula imveliso yomgubo ocolekileyo kunye nokunciphisa ukusetyenziswa kwegesi kukhokelela ekuphuhliseni ulwalathiso lweteknoloji ye-atomization ye-ultrasonic.

1.2.1 Iindidi ezahlukeneyo zemilomo ye-atomization ye-ultrasonic

Irhasi ye-atomizing yonyusa isantya kunye namandla ngombhobho, ngaloo ndlela yaphula ngokufanelekileyo isinyithi esimanzi kwaye ilungiselela umgubo ohlangabezana neemfuno. I-nozzle ilawula ukuhamba kunye nephethini yokuhamba kwe-atomized medium, kwaye idlala indima ebalulekileyo kwinqanaba le-atomization esebenzayo kunye nokuzinza kwenkqubo ye-atomization, kwaye iteknoloji ephambili ye-atomization ye-ultrasonic. Kwinkqubo yokuqala ye-atomization yegesi, i-free-fall nozzle structure yayisetyenziswa ngokubanzi. Lo mlomo ulula kuyilo, akulula ukuvalelwa, kwaye inkqubo yokulawula ilula, kodwa ukusebenza kwayo kwe-atomization ayiphezulu, kwaye ifaneleka kuphela ukuveliswa kwe powder kunye nobukhulu be-particle ye-50-300 μm. Ukuze kuphuculwe ukusebenza kakuhle kwe-atomization, imilomo ethintelayo okanye imilomo yeatomizi edityaniswe ngokuqinileyo iye yaphuhliswa kamva. Umbhobho oqinileyo okanye othintelayo wenza mfutshane umgama wokubhabha kwegesi kwaye unciphise ilahleko yamandla ekinetic kwinkqubo yokuhamba kwerhasi, ngaloo ndlela inyusa isantya kunye noxinaniso lokuhamba kwerhasi edibana nesinyithi, kunye nokunyusa isivuno somgubo ocolekileyo.

1.2.1.1 uMlomo weSilothi esiSekethekileyo

Uxinzelelo oluphezulu lwe-ultrasonic lungena kwi-nozzle tangentially. Emva koko ikhutshwe ngesantya esiphezulu ukuze yenze i-vortex

Ukuphuhlisa uShicilelo lwe-3D, i-China idinga ukuzakhela uTyayinge lokuyila kunye neChayini yezoShishino.

Kule minyaka mibini idlulileyo, uphuhliso lweshishini lemveliso elongezelelweyo liye laphakama kwinqanaba leqhinga lesizwe. Amaxwebhu afana ne "Made in China 2025" kunye ne "National Additive Manufacturing Industry Action Plan (2015-2016)" akhutshiwe. Ishishini lemveliso elongezelelweyo liphuhliswe ngokukhawuleza. Ukubaluleka kwamashishini asekelwe kubuchwepheshe buyakhula. Nangona kunjalo, kuba imboni yokuvelisa ikwinqanaba lokuqala lophuhliso, isabonisa iimpawu zesikali esiphantsi. Iingcali ziyavuma ukuba izixhobo ezithunyelwa kwamanye amazwe ngoku "zihlasela" imarike yaseTshayina. Ukuthatha izixhobo zoshicilelo zesinyithi njengomzekelo, amazwe angaphandle aphumeza ukuthengiswa okuhlanganisiweyo kwezixhobo, isoftware, izixhobo kunye neenkqubo. ilizwe lam kufuneka likhawulezise uphando kunye nophuhliso lwetekhnoloji engundoqo kunye netekhnoloji yokuqala, kwaye lenze eyalo ikhonkco lokusungula kunye nekhonkco lemizi-mveliso.

Ithemba lemarike lilungile

Ngokwengxelo kaMcKinsey, imveliso eyongezelelweyo ikwindawo yesithoba phakathi kwetekhnoloji ye-12 enempembelelo ephazamisayo kubomi bomntu, ngaphambi kwezixhobo ezintsha kunye nerhasi ye-shale, kwaye kuqikelelwa ukuba ngo-2030 ukuveliswa okongeziweyo kuya kufikelela kubukhulu bemarike malunga ne-1 yetriliyoni yeedola. Ngo-2015, ingxelo iqhubele phambili le nkqubo, iphikisana ukuba ngo-2020, oko kukuthi, kwiminyaka emithathu kamva, ubungakanani bemakethi eyongezelelweyo yemveliso yomhlaba wonke inokufikelela kwinzuzo ye-550 yeebhiliyoni zeedola zaseMelika. Ingxelo kaMcKinsey ayiniki mdla.

U-Lu Bingheng, isifundiswa se-Academy yaseTshayina yobuNjineli kunye nomlawuli we-National Additive Manufacturing Innovation Centre, wasebenzisa "ezine nesiqingatha" ukushwankathela amathemba emarike exesha elizayo okwenziwa kwemveliso eyongezelelweyo.

Ngaphezu kwesiqingatha sexabiso lemveliso kwixesha elizayo lenzelwe;

Ngaphezu kwesiqingatha semveliso yemveliso yenziwe ngokwezifiso;

Ngaphezu kwesiqingatha seemodeli zemveliso zigcwele abantu;

Ngaphezu kwesiqingatha sezinto ezintsha ezenziwe ngabaenzi.

Imveliso eyongezelelweyo yiteknoloji ephazamisayo ekhokelela ekuphuhlisweni kweshishini lokuvelisa. Bubuchwephesha obufanelekileyo bokuxhasa uyilo lokuyila, imveliso eyenziwe ngokwezifiso, ukuveliswa komenzi kunye nokuveliswa kwe-crowdsourcing. "Okubaluleke ngakumbi, ukuveliswa okongeziweyo yiteknoloji enqabileyo ehambelana nehlabathi kwilizwe lam. Okwangoku, uphando lwaseChina malunga nokuprintwa kwe-3D luhamba phambili kwihlabathi. "

U-Lu Bingheng uthe ngoku, kuxhomekeke kwi-atomization yesinyithi yoshicilelo olukhulu lwe-3D kunye nezixhobo zokugaya eziphuhliswe lilizwe lam ngokwalo, i-China ikwimo yezizwe ngezizwe ekusetyenzisweni kweendawo ezinkulu ezithwele inqwelomoya, kwaye isebenza njengesixhobo sokusebenza njengesixhobo sokwenza inqwelomoya. Iqela loncedo lokuqala kuphando kunye nophuhliso lweenqwelomoya zomkhosi kunye neenqwelomoya ezinkulu. Ngaphaya koko, i-titanium alloy enkulu yezakhiwo isetyenzisiwe kuphando kunye nophuhliso lwezixhobo zokumisa inqwelomoya kunye neC919.

Ngokwesicelo, umthamo welizwe lam ofakelweyo wezixhobo zodidi lwemizi-mveliso ukwindawo yesine kwihlabathi, kodwa izixhobo ezithengiswayo zoshicilelo lwentsimbi zisebuthathaka ngokwentelekiso, kwaye ubukhulu becala zixhomekeke ekuthengisweni kwamanye amazwe. Nangona kunjalo, ngokutsho kwe-Academician Lu Bingheng, injongo iyonke yokwenziwa kwemveliso eyongezelelweyo yaseTshayina kukuphumeza indawo yesibini ngobukhulu efakwe emhlabeni kunye neyesithathu ngobukhulu imveliso yezixhobo kunye neentengiso kwihlabathi phakathi kweminyaka emi-5; kunye nesesibini ngobukhulu esifakelweyo umthamo wehlabathi, izixhobo ezingundoqo kunye nobuchwepheshe bokuqala, kunye nokuthengiswa kwezixhobo kwiminyaka eyi-10. Ukufezekisa "Yenziwe eTshayina 2025" ngo-2035.

Uphuhliso lwamashishini luyakhawuleza

Idatha ibonisa ukuba umyinge wokukhula komlinganiselo wobungakanani bemarike yemveliso eyongezelelweyo kule minyaka mithathu idlulileyo. Izinga lophuhliso lweli shishini e-China liphezulu kunomyinge wehlabathi.

Imiqondiso: idla ngokubhekisa koko kwenziwayo ukulawula iinkqubo ezithile zesiqhelo ngaphakathi ekhampasini

Iimpawu, ezinjengalezi: iimpawu zeentyantyambo kunye neengca, akukho zibonakaliso zokunyuka, njl. Ukuncipha, kodwa kwintsimi yenkonzo, izinga lokukhula likhawuleza kakhulu ngenxa yokuphucula ukuqatshelwa kwabathengi. "Ngokukodwa ekuqhutyweni kwemveliso kunye nokuveliswa, umthamo wethu wokuodola uphindwe kabini." Isiseko soLimo soShicilelo lwe-Weinan 3D kwiPhondo laseShaanxi, ngenkxaso yorhulumente wasekhaya, iguqule iingenelo zeteknoloji yoshicilelo ye-3D ibe yinzuzo yoshishino kwaye yakhuthaza ukuphuculwa nokuguqulwa kwamashishini emveli. Imeko eqhelekileyo yokuqonda uphuhliso lweqela.

Kugxilwe kwingqikelelo yokufakwa kwemveliso ye-"3D yoshicilelo +", ayikona nje ukuphuhlisa ishishini loshicilelo lwe-3D, kodwa kugxilwe kwimveliso yezixhobo zoshicilelo ze-3D, uphando kunye nophuhliso kunye nokuveliswa kwezixhobo zetsimbi zoshicilelo lwe-3D, kunye noqeqesho. ye-3D yoshicilelo lwetalente ejolise kwisicelo. Imiliselwe kumashishini aphambili asekhaya, kugxininise ekuphunyezweni kwezicelo zemiboniso yoshicilelo lwe-3D yoshicilelo, ukukhawulezisa ukudityaniswa koshicilelo lwe-3D kunye namashishini emveli, kunye nokuphumeza uthotho lwe-3D yoshicilelo + imifuziselo yoshishino efana ne-3D yoshicilelo + inqwelomoya, imoto, inkcubeko kunye nobuchule, ukuphosa, imfundo, njl., ngoncedo loshicilelo lwe-3D Iinzuzo zobuchwepheshe bokushicilela, ukusombulula ubunzima bobugcisa kunye namanqaku eentlungu kumashishini emveli, ukuguqula nokuphucula amashishini emveli, kunye nokwazisa kunye nokufukamela iintlobo ezahlukeneyo zamashishini amancinci naphakathi.

Ngokutsho kwezibalo, ukususela ngoMeyi 2017, inani lamashishini liye lafikelela kwi-61, kwaye ngaphezu kweeprojekthi ze-50 ezifana nokubumba kwe-3D, i-3D, i-3D yoomatshini boshishino, izixhobo ze-3D, kunye neeprojekthi zenkcubeko kunye nezobugcisa ze-3D zigcinwe, ekulindeleke ukuba ziphunyezwe. Kulindeleke ukuba ekupheleni konyaka, inani lamashishini libe ngaphezu kwe-100.

Ukuvuselela ikhonkco lokusungula kunye nekhonkco lemizi-mveliso

Ngaphandle kophuhliso olukhawulezileyo lweshishini lelizwe lam elongezelelweyo lokuvelisa, ishishini lisekwinqanaba lokuqala lophuhliso kwaye lisenazo iimpawu zesikali esisezantsi. Nangona kunjalo, ukungabikho kokuvuthwa kwezobuchwepheshe, iindleko eziphezulu zesicelo, kunye nobubanzi besicelo esincinci kubangele ukuba ishishini lilonke libe kwimeko "encinci, ihlakazekile kwaye ibuthathaka". Nangona iinkampani ezininzi ziye zaqala ukubeka unyawo kwintsimi yokuvelisa okongeziweyo, kukho ukunqongophala kweenkampani ezihamba phambili eziqhutywayo, isikali soshishino sincinci. Isifundiswa uLu Bingheng uthe ngokungafihlisiyo njengenye yetekhnoloji ephambili yenguquko yemveliso yexesha elizayo, uphuhliso lwemveliso eyongezelelweyo kufuneka lukhawuleziswe, kuba itekhnoloji yoshicilelo ye-3D ikwixesha lokuvuthuza kwetekhnoloji, ixesha lokuqalisa ishishini, kwaye ixesha "lokubamba" lamashishini. Imfuno enkulu yentengiso inokuqhuba uphuhliso lwetekhnoloji kunye nendawo yezixhobo, ekufuneka ikhuselwe kwaye isetyenziswe ngokupheleleyo ukukhokela kunye nokuxhasa ukwenziwa kwezixhobo zethu.

Ngoku izixhobo ezithunyelwa ngaphandle "zihlasela" imarike yaseTshayina. Kwizixhobo zoshicilelo lwesinyithi, amazwe angaphandle aphumeza ukuthengiswa kwezinto ezihlanganisiweyo, isoftware, izixhobo kunye neenkqubo. Iinkampani zaseTshayina kufuneka ziphuhlise itekhnoloji engundoqo kunye netekhnoloji yokuqala ukwenza eyabo into entsha kunye namatyathanga oshishino.

Abangaphakathi kwimizi-mveliso bathi kwishishini langoku lasekhaya loshicilelo lwe-3D, inqanaba lophando lwetekhnoloji kunye nophuhliso lusetyenziswe ngokupheleleyo kushishino, kwaye impumelelo emininzi yetekhnoloji ikwinqanaba lelebhu kuphela. Izizathu eziphambili zale ngxaki zezi: okokuqala, ngenxa yemigangatho eyahlukeneyo, ukufikelela Iziqinisekiso azifezekanga, kwaye kukho imiqobo engabonakaliyo yokungena; okwesibini, amaziko ophando lwezenzululwazi kunye namashishini abanazo iziphumo zesikali, bakwimo yokulwa bodwa, abanalungelo lokuthetha kwiingxoxo zoshishino, kwaye bakwimeko embi; Ishishini elitsha aliqondwa kakuhle, kwaye kukho iipuzzle okanye ukungaqondi kakuhle, okukhokelela kwisantya esicothayo sokusetyenziswa kwetekhnoloji.

Indlela yoPhuhliso lwe-Atomization yeSixhobo sokuPulverizing kwixesha elizayo

Kusekho iintsilelo ezininzi ekuqondeni itekhnoloji yoshicilelo lwe-3D kuzo zonke iinkalo zoshishino lwemveliso yaseTshayina. Xa sijonga imeko yophuhliso, ukuza kuthi ga ngoku ushicilelo lwe-3D alukhange lufikelele kwishishini eliqolileyo, ukusuka kwizixhobo ukuya kwiimveliso ukuya kwiinkonzo ezisekwinqanaba "lokudlala eliphambili". Nangona kunjalo, ukusuka kurhulumente ukuya kumashishini eTshayina, amathuba ophuhliso lweteknoloji yoshicilelo ye-3D ayaziwa ngokubanzi, kwaye urhulumente kunye noluntu ngokubanzi banikele ingqalelo kwimpembelelo yexesha elizayo le-3D yoshicilelo lwentsimbi ye-atomization yokucofa iteknoloji kwimveliso ekhoyo yelizwe lam, uqoqosho, kunye neemodeli zokuvelisa.

Ngokutsho kwedatha yophando, okwangoku, imfuno yelizwe lam yeteknoloji yoshicilelo lwe-3D ayigxininisi kwisixhobo, kodwa ibonakaliswe kwiintlobo ezahlukeneyo ze-3D zokushicilela kunye nemfuno yeenkonzo zokulungisa i-arhente. Abathengi bemizi-mveliso awona mandla aphambili ekuthengeni izixhobo zoshicilelo ze-3D kwilizwe lam. Izixhobo abazithengayo zisetyenziswa ikakhulu kuphapho, kwi-aerospace, kwiimveliso ze-elektroniki, ezothutho, ukuyila, ukuyila kwenkcubeko kunye namanye amashishini. Okwangoku, umthamo ofakiweyo wabashicileli be-3D kumashishini aseTshayina malunga ne-500, kwaye izinga lokukhula lonyaka li malunga ne-60%. Nangona kunjalo, ubungakanani bemarike yangoku bumalunga ne-100 yezigidi zeeyuan ngonyaka. Imfuno enokubakho ye-R&D kunye nokuveliswa kwemathiriyeli yoshicilelo ye-3D ifikelele phantse kwibhiliyoni enye yeyuan ngonyaka. Ngokuthandwa kunye nenkqubela phambili yeteknoloji yezixhobo, isikali siya kukhula ngokukhawuleza. Kwangaxeshanye, iinkonzo zokusetyenzwa eziphathisiweyo ezinxulumene noshicilelo lwe-3D zithandwa kakhulu, kwaye uninzi lweearhente zoshicilelo lwe-3D Inkampani yezixhobo iqole kakhulu kwinkqubo ye-laser sintering kunye nesicelo sezixhobo, kwaye inokubonelela ngeenkonzo zokulungisa zangaphandle. Ekubeni ixabiso lesixhobo esinye ngokubanzi lingaphezulu kwe-5 yezigidi zeeyuan, ukwamkelwa kweemarike akuphezulu, kodwa inkonzo yokucubungula i-arhente ithandwa kakhulu.

Uninzi lwezixhobo ezisetyenziswa kwilizwe lam 3D yoshicilelo metal atomization pulverizing izixhobo zibonelelwa ngokuthe ngqo ngabavelisi beprototyping ekhawulezayo, kwaye unikezelo lomntu wesithathu wezinto eziqhelekileyo alukaphunyezwa, okukhokelela kwiindleko eziphezulu kakhulu zezinto. Kwangaxeshanye, akukho phando malunga nokulungiswa komgubo onikezelwe kushicilelo lwe-3D eTshayina, kwaye kukho iimfuno ezingqongqo kubungakanani besuntswana losasazo kunye nomxholo weoksijini. Ezinye iiyunithi zisebenzisa umgubo wokutshiza wesiqhelo endaweni yoko, onezinto ezininzi ezingasebenziyo.

Uphuhliso kunye nokuveliswa kwezinto ezisebenza ngeendlela ezininzi ngundoqo kwinkqubela phambili yezobuchwepheshe. Ukusombulula iingxaki zentsebenzo kunye neendleko zezixhobo kuya kukhuthaza ngcono uphuhliso lwetekhnoloji yeprototyping ekhawulezileyo eTshayina. Okwangoku, uninzi lwezixhobo ezisetyenziswa kwilizwe lam loshicilelo lwe-3D olukhawulezayo lwetekhnoloji yeprototyping kufuneka luthengwe kumazwe angaphandle, okanye abenzi bezixhobo batyale amandla amaninzi kunye neemali zokuziphuhlisa, ezixabisa kakhulu, okukhokelela ekunyukeni kweendleko zemveliso, ngelixa. izinto zasekhaya ezisetyenziswe kulo matshini zinamandla aphantsi kunye nokuchaneka. . Ukwenziwa kwendawo yezinto zoshicilelo ze-3D kunyanzelekile.

I-Titanium kunye ne-titanium alloy powders okanye i-nickel-based kunye ne-cobalt-based based superalloy powders kunye nomxholo ophantsi we-oksijeni, ubungakanani beqhekeza elincinci kunye ne-sphericity ephezulu iyafuneka. Ubungakanani bepowder particle ubukhulu becala -500 mesh, umxholo we-oksijeni kufuneka ube ngaphantsi kwe-0.1%, kwaye ubungakanani be-particle bufanayo Okwangoku, i-powder-alloy powder ephezulu kunye nezixhobo zokuvelisa zisaxhomekeke kakhulu ekungenisweni kwamanye amazwe. Kumazwe angaphandle, izinto ezikrwada nezixhobo zidla ngokudityaniswa zize zithengiswe ukuze kufunyanwe ingeniso eninzi. Ukuthatha i-nickel-based powder njengomzekelo, ixabiso lezinto eziluhlaza malunga ne-200 yuan / kg, ixabiso leemveliso zasekhaya ngokuqhelekileyo li-300-400 yuan / kg, kwaye ixabiso le-powder ephuma kwamanye amazwe lihlala lingaphezulu kwe-800 yuan / kg.

Umzekelo, impembelelo kunye nokuguquguquka kokwakheka komgubo, ukufakwa kunye neepropathi ezibonakalayo kwiitekhnoloji ezinxulumene ne-3D yoshicilelo lwentsimbi ye-atomization izixhobo zokugaya umgubo. Ke ngoko, ngokweemfuno zokusetyenziswa komxholo weoksijini ephantsi kunye nomgubo ocolekileyo wobungakanani besuntswana, kuseyimfuneko ukwenza umsebenzi wophando onje ngokwakheka koyilo lwe-titanium kunye ne-titanium alloy powder, itekhnoloji yokugaya igesi ye-atomization yomgubo ocolekileyo, kunye impembelelo yeempawu zomgubo ekusebenzeni kwemveliso. Ngenxa yokunciphisa iteknoloji yokugaya e-China, kunzima ukulungiselela i-powder-grained powder ngoku, isivuno somgubo siphantsi, kwaye umxholo we-oksijeni kunye nezinye izinto ezingcolileyo ziphezulu. Ngethuba lenkqubo yokusetyenziswa, i-powder melting state ihambelana nokungalingani, okubangelwa umxholo ophezulu we-oxide inclusions kunye nemveliso ye-denser kwimveliso. Ezona ngxaki ziphambili zomgubo wengxubevange yasekhaya zikumgangatho wemveliso kunye nozinzo lwebhetshi, kubandakanywa: ① uzinzo lwamacandelo omgubo (inani lokufakwa, ukufana kwamacandelo); ② umgubo ngokwasemzimbeni Ukuzinza kokusebenza (ubungakanani besuntswana losasazo, i-powder morphology, fluidity, ratio exegeyo, njl.); ③ ingxaki yesivuno (isivuno esiphantsi somgubo kwicandelo elimxinwa lobungakanani besuntswana), njl.

Umboniso weMveliso

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur