Iinkqubo zeGranulating

Iinkqubo ze-granulating ezikwabizwa ngokuba "zidutyulo", ziyilwe kwaye zisetyenziselwa ngokukodwa iibhululi zegranulating, i-sheet, i-strips yesinyithi okanye isinyithi esilahliweyo kwiinkozo ezifanelekileyo.Iitanki ze-granulating zilula kakhulu ukususa ukucima.Umqheba wokutsalela ngaphandle ukwenzela ukususwa lula kofakelo lwetanki.Izixhobo ezikhethiweyo zomshini wokuphosa uxinzelelo lwe-vacuum okanye umatshini oqhubekayo wokuphosa kunye netanki ye-granulating isisombululo se-granulating ngamaxesha athile.Amatanki egranulating ayafumaneka kubo bonke oomatshini kuthotho lweVPC.Iinkqubo zodidi oluqhelekileyo lwegranulating zinetanki enamavili amane ahamba ngokulula ngaphakathi nangaphandle.

-

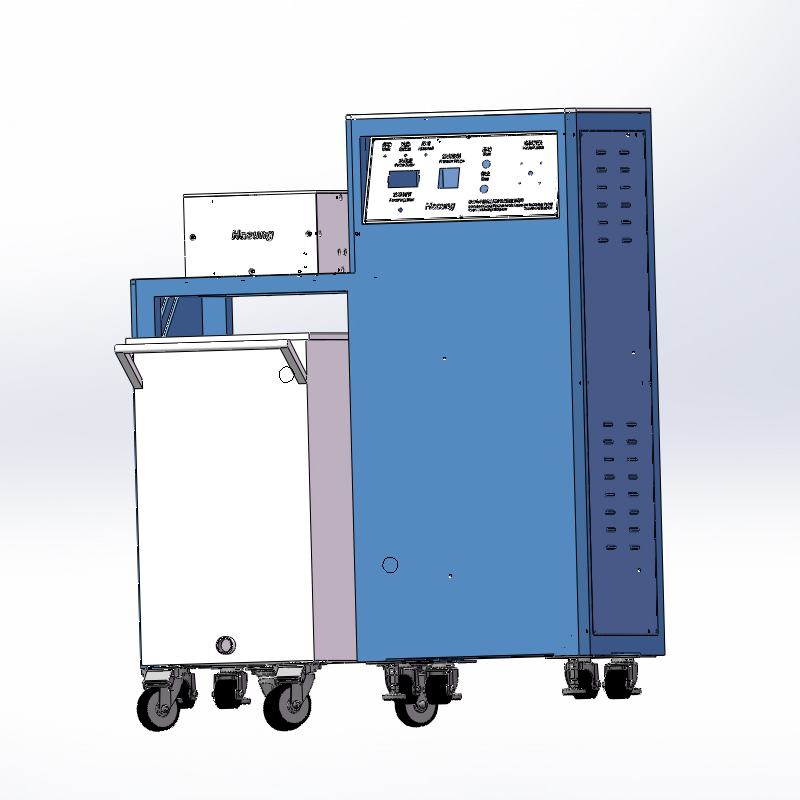

Metal Granulator Machine for Gold Silver Copper 2kg 3kg 5kg 6kg 8kg10kg 15kg

1. Ngokulawulwa kobushushu, ukuchaneka ukuya kuthi ga ku-±1 °C.

2. Uyilo lwe-Ultra-human, ukusebenza kulula kunabanye.

3. Sebenzisa isilawuli seMitsubishi esivela kumazwe angaphandle.

4. I-Silver Granulator ene-temperature control (i-Gold Silver Granulating Machine, i-Silver Granulating Machine).

5. Lo matshini uthatha i-IGBT iteknoloji yokufudumeza ephuculweyo, umphumo wokuphosa ulungile kakhulu, inkqubo izinzile kwaye ikhuselekile, umthamo wegolide otyhidiweyo unokuzikhethela, kwaye ukucaciswa kwensimbi ye-granulated kunokuzikhethela.

6. Isantya segranulation sikhawuleza kwaye akukho ngxolo.Uvavanyo olugqibeleleyo kunye nemisebenzi yokukhusela yenza umatshini wonke ukhuseleke kwaye uhlale ixesha elide.

7. Umatshini unoyilo lokuhlukana kwaye umzimba unendawo ekhululekile.

-

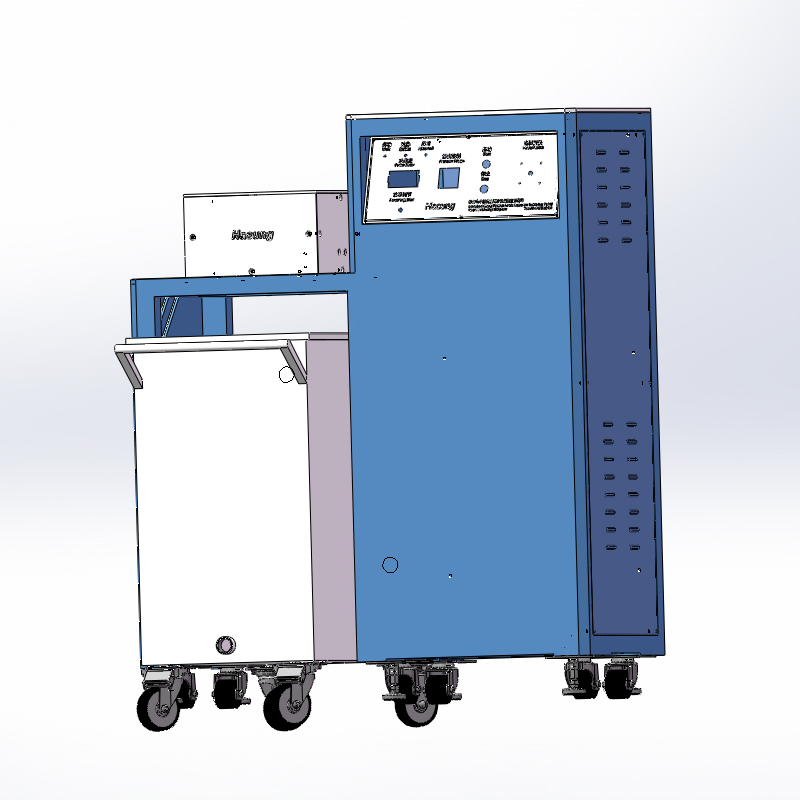

I-Platin Granulating System Machine Granulating 10kg

IHasung Platinum Shot Maker Granulating Machine xa kuthelekiswa neemveliso ezifanayo kwimarike, ineenzuzo ezibalaseleyo ezingenakuthelekiswa nanto ngokubhekiselele ekusebenzeni, umgangatho, ukubonakala, njl., kwaye uyonwabela idumela elihle kwimarike.I-Hasung ishwankathela iziphene zeemveliso ezidlulileyo, kwaye ngokuqhubekayo iyawaphucula.Iinkcukacha ze-Hasung Platinum Shot Maker Granulating Machine zingenziwa ngokwezifiso ngokweemfuno zakho.

Iingenelo eziphambili zezizukulwana ezitsha ze-shotmaker

Ukufakwa lula kwetanki ye-granulating kunye neqonga

Ukusebenza komgangatho ophezulu wegranulating

Uyilo lwe-ergonomically kunye ngokugqibeleleyo olulungeleleneyo lokuphatha ngokukhuselekileyo nokulula

Ukuziphatha okulungiselelwe umjelo wamanzi okupholisa

Ukwahlula okuthembekileyo kwamanzi kunye neegranules -

I-Vacuum Shot Maker ye-Golden Silver Copper 1kg 2kg 4kg 8kg

Uyilo lwale nkqubo ye-vacuum granulator isekwe kwiimfuno zokwenyani zenkqubo yentsimbi exabisekileyo ngokusebenzisa itekhnoloji yanamhlanje yokufudumeza induction.

Ivacuum granulator isetyenziselwa ukwenza umgangatho ophezulu kunye neenkozo zenkosi ezilinganayo kwiintsimbi ezixabisekileyo ezifana negolide, isilivere, ubhedu, kunye nealloys, ukuqala kwizinto ezikrwada ezinyibilikisiweyo ngokufudumeza kweHasung kwindawo ekhuselayo yegesi, emva koko yehla kwitanki yamanzi idlula. ngecrucible enemingxuma emininzi esebenza njenge-flow breaker.

I-vacuum granulator ithatha i-vacuum ngokupheleleyo kunye nokunyibilika kwegesi engasebenziyo kunye ne-granulating, umatshini unokushukumisa ngokuzenzekelayo ekunyibilikeni, ukushukumisa i-electromagnetic, kunye nefriji kwigumbi lokunyibilikisa elivaliweyo + le-vacuum / inert, ukuze imveliso ibe neempawu zokungabi na-oxidation, super. ilahleko ephantsi, akukho pores, akukho ukwahlula ngombala, kunye nembonakalo entle kunye nobukhulu obufanayo.

Esi sixhobo sisebenzisa inkqubo yolawulo lwenkqubo yeMitsubishi PLC, i-SMC pneumatic kunye nePanasonic servo motor drive kunye namanye amacandelo ebhrendi awaziwayo ekhaya nakwamanye amazwe.

-

INkqubo yokuVula iGranulating yeGolide yeSiliva yeSiliva 20kg 50kg 100kg

Vacuum vacuum granulates amasuntswana entsimbi exabisekileyo yokuphosa intambo yokudibanisa: igolide, isilivere kunye nobhedu, ucingo lwe-bonding lusetyenziswa ikakhulu kwizinto ze-semiconductor, izixhobo ze-photovoltaic welding, izixhobo zonyango, oomatshini bobukrelekrele bokwenziwa. , ishidi lesinyithi, okanye i-scraps kwiinkozo ezifanelekileyo.Iitanki ze-granulating zilula kakhulu ukususa ukucoca.I-HS-VGR High Vacuum Granulating Machines ifumaneka nge-crucible capacity ukusuka kwi-20kg ukuya kwi-100kg.Izinto zomzimba zisebenzisa i-304 yensimbi engenasici eqinisekisa umgangatho wobomi obude usebenzisa, kunye noyilo lwemodyuli ukuzalisekisa umgangatho ofunekayo.

Usetyenziso oluphambili:

1. Ukulungiswa kwee-alloys ezivela kwigolide kunye ne-master alloy

2. Ukulungiswa kwamacandelo e-alloy

3. Ukulungiswa kwee-alloys ezivela kumacandelo

4. Ukucocwa kwentsimbi esele yenziwe

5. Ukwenza iinkozo zetsimbi kwiintengiso zentsimbi exabisekileyoUluhlu lweVGR lwaphuhliswa ukuveliswa kweegranule zetsimbi ezinobukhulu obuziinkozo phakathi kwe-1.5 mm kunye ne-4mm.Iinkqubo zisekelwe kwiiyunithi ze-Hasung granulation, kodwa onke amacandelo aphambili, ngakumbi inkqubo yejethi, luphuhliso olukhethekileyo.

Umthamo omkhulu onje nge-100kg ye-vacuum granulating system iyakhethwa ukuba uxhotyiswe nge-Mitsubishi PLC ye-Touch Panel system control panel.

Izixhobo ezikhethiweyo zoxinzelelo lwe-vacuum okanye umatshini oqhubekayo wokuphosa kunye netanki ye-granulating isisombululo esifanelekileyo se-granulating ngamaxesha.Amatanki granulating ziyafumaneka kubo bonke oomatshini kuthotho VC.

Ezona zinto ziluncedo kwizizukulwana ezitsha zabadubulayo:

1. Ufakelo olulula lwetanki yegranulating

2. Ukutshintsha ngokukhawuleza phakathi kwenkqubo yokuphosa kunye ne-granulating

3. Uyilo lwe-ergonomically kunye nolungelelwaniso olugqibeleleyo lokuphatha ngokukhuselekileyo nokulula

4. Ukuziphatha okulungiselelweyo kokuhamba kwamanzi okupholisa

5. Ukwahlula okuthembekileyo kwamanzi kunye neegranules

6. Awona maqela anamandla kwaye asebenzayo kumaqela okucoca iintsimbi ezixabisekileyo.

7. Ukonga amandla, ukunyibilika ngokukhawuleza. -

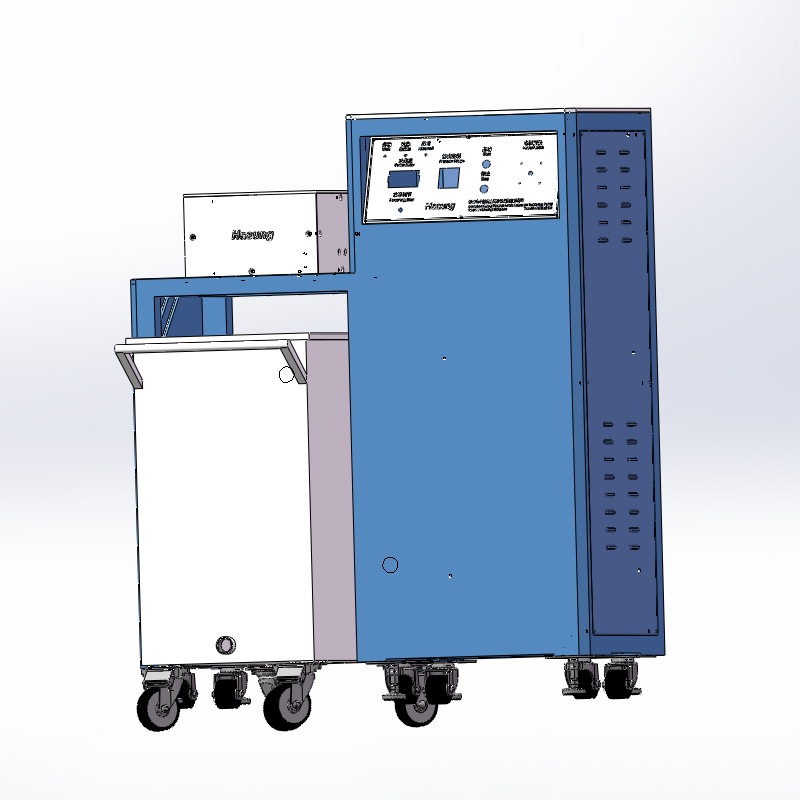

Metal Granulating Machine for Gold Silver Copper Alloy 20kg 30kg 50kg 100kg 150kg

1. Ngokulawulwa kobushushu, ukuchaneka ukuya kuthi ga ku-±1 °C.

2. Uyilo lwe-Ultra-human, ukusebenza kulula kunabanye.

3. Sebenzisa isilawuli seMitsubishi esivela kumazwe angaphandle.

4. I-Silver Granulator ene-temperature control (i-Gold Silver Granulating Machine, i-Silver Granulating Machine).

5. Lo matshini uthatha i-IGBT iteknoloji yokufudumeza ephuculweyo, umphumo wokuphosa ulungile kakhulu, inkqubo izinzile kwaye ikhuselekile, umthamo wegolide otyhidiweyo unokuzikhethela, kwaye ukucaciswa kwensimbi ye-granulated kunokuzikhethela.

6. Isantya segranulation sikhawuleza kwaye akukho ngxolo.Uvavanyo olugqibeleleyo kunye nemisebenzi yokukhusela yenza umatshini wonke ukhuseleke kwaye uhlale ixesha elide.

7. Umatshini unoyilo lokuhlukana kwaye umzimba unendawo ekhululekile.

-

Ubungakanani obubambeneyo beMetal Granulator yesiXhobo sokuGranula seGolide yeSilivere

Abadubuli besinyithi abancinci.Ngokulawulwa kobushushu, ukuchaneka ukuya kuthi ga ku-±1°C.

Uyilo lwe-Ultra-human, ukusebenza kulula kunabanye.

Sebenzisa isilawuli seMitsubishi esivela kumazwe angaphandle.

Faka isicelo VC series vacuum umatshini wokugalela uxinzelelo, ixhotyiswe 304 SS itanki yamanzi.Igranulator enolawulo lobushushu (Umatshini wokuCasa iiNkozo zeSilivere, uMatshini weSilver Granulating).

Lo matshini wamkela itekhnoloji yokufudumeza ephucukileyo yaseJamani IGBT, isiphumo sokuphosa silungile kakhulu, inkqubo izinzile kwaye ikhuselekile, umthamo wegolide otyhidiweyo unokuzikhethela, kwaye ukucaciswa kwesinyithi esinegranulated kunokuzikhethela.Isantya segranulation siyakhawuleza kwaye akukho ngxolo.Uvavanyo olugqibeleleyo kunye nemisebenzi yokukhusela yenza umatshini wonke ukhuseleke kwaye uhlale ixesha elide.Umatshini unoyilo olwahlulahlulo kwaye umzimba unendawo ekhululekileyo.Ukusebenzisa ngaphandle kwecompressor yomoya, ukuphosa ngesivalo sokuvula ngoomatshini.

Le nkqubo AG Series granulating ilungele umthamo omncinane ukusuka 1kg ukuya 6kg umthamo (igolide), ilungile kubathengi abanendawo encinane.

Yintoni igranulation yesinyithi?

Igranulation (isuka kwisiLatini: igranum = “inkozo”) bubuchule bomkhandi wegolide apho umphezulu welitye elinqabileyo uhonjiswe ngeengqukuva ezincinci zentsimbi exabisekileyo, ebizwa ngokuba ziigranules, ngokwepateni yoyilo.Izinto zakudala zakudala ezifunyenwe ngamatye anqabileyo ezenziwe ngobu buchule zifunyenwe kumangcwaba asebukhosini aseUre, eMesopotamiya kwaye zibuyele kwi-2500 BC Ukusuka kule ndawo, ubuchule busasazeka kwi-Anatolia, eSiriya, ukuya eTroy (2100 BC) kwaye ekugqibeleni ukuya e-Etruria. (kwinkulungwane yesi-8 BC).Yayikukunyamalala kancinci kancinci kwenkcubeko yamaEtruria phakathi kwenkulungwane yesithathu neyesibini ngaphambi kweXesha lethu Eliqhelekileyo okwabangela ukuncipha kwegranulation.1 AmaGrike amandulo nawo ayesebenzisa umsebenzi wokugranulation, kodwa yayiziingcweti zase-Etruria ezathi zaduma ngobu buchule ngenxa yolu buchule. ukuthunyelwa kwabo okungaqondakaliyo kwe-powder granulation2 ngaphandle kokusetyenziswa okubonakalayo kwe-solder enzima.

I-granulation mhlawumbi yeyona nto ingaqondakaliyo kwaye inomdla kwiindlela zakudala zokuhombisa.Yaziswa ngamagcisa uFenici noGreci ukuya e-Etruria ngenkulungwane yesi-8 BC, apho ulwazi lwesinyithi kunye nokusetyenziswa kwesinyithi esixabisekileyo sele sikwinqanaba eliphezulu, iingcali zegolide zase-Etruscan zenza obu buchule babo bokudala imisebenzi yobugcisa obuntsonkothileyo kunye nobuhle obungalinganiyo.

Ngexesha lesiqingatha sokuqala se-1800's ukugrunjwa okuninzi kwenziwa kwindawo yaseRoma (Cerveteri, Toscanella kunye neVulci) kunye ne-Southern Russia (i-Kertch kunye ne-Taman peninsulas) eyatyhila ubucwebe bamandulo be-Etruscan kunye ne-Greek.La matye anqabileyo ayehonjiswe ngegranulation.Ubucwebe beza kwingqalelo yeNtsapho yaseCastellani yamatye anqabileyo ababebandakanyeka kakhulu kuphando lobucwebe bamandulo.Izinto ezifunyenwe kwiindawo zokungcwaba zase-Etruscan zatsala ingqalelo enkulu ngenxa yokusetyenziswa kweegranules ezintle kakhulu.U-Alessandro Castellani wafunda ezi zixhobo zobugcisa ngokweenkcukacha ezinkulu ukuze azame ukutyhila indlela yazo yokwenza izinto.Kwakungekho kwasekuqaleni kwenkulungwane yama-20, emva kokufa kukaCastellani, apho iphazili ye-colloidal/eutectic soldering yade yasonjululwa.

Nangona imfihlo yahlala iyimfihlelo kumaCastellanis kunye nabantu ababephila ngexesha labo, ubucwebe obusandul' ukufunyanwa base-Etruscan bavuselela ubucwebe bezacholo zakudala malunga ne-1850's.Ubuchule bokwenza iGoldsmithing bafunyanwa obenze ukuba uCastellani kunye nabanye baphinde bavelise kwakhona obunye ubucwebe bamandulo obugqwesileyo kwezakha zembiwa.Uninzi lwezi ndlela zobuchule zazahluke kakhulu kwezo ziqeshwe yi-Etruscans kodwa zivelise iziphumo ezifikelelekayo.Uninzi lwezi zinto zobucwebe bezacholo ze-Archaeological Revival ngoku zikwiingqokelela ezibalulekileyo zobucwebe kwihlabathi liphela, kunye noogxa babo bamandulo.

IZIBONELELO

Iigranules zenziwe kwi-alloy efanayo kunye nesinyithi apho ziya kusetyenziswa khona.Enye indlela iqala ngokuqengqa ishiti elicekethekileyo lesinyithi kunye nokusika imiphetho emxinwa kakhulu ecaleni komphetho.Umphetho unqunyulwe kwaye umphumo zininzi izikwere ezincinci okanye iiplatelet zetsimbi.Obunye ubuchule bokudala iinkozo busebenzisa ucingo olubhityileyo olubhityileyo olujikeleze i-mandrel ebhityileyo, njengenaliti.Ikhoyili ke isikwa ibe ngamakhonkco amancinci okutsiba.Oku kudala amakhonkco alinganayo kakhulu akhokelela kwiigranules ezinobungakanani obulinganayo.Injongo kukudala iingqukuva ezininzi ezinobukhulu obufanayo ezinobubanzi obungekho ngaphezulu kwe-1 mm.

Iiplatelet zentsimbi okanye amakhonkco okutsiba aqatywe ngomgubo wamalahle ukuze athintele ukuba angabambeleli kunye ngexesha lokudubula.Umzantsi we-crucible ugqunywe ngumaleko wamalahle kunye neentsimbi zetsimbi zifafazwe ukuze zilinganiswe ngokulinganayo.Oku kulandelwa ngumaleko omtsha we-charcoal powder kunye nezinye iziqwenga zetsimbi kude kube yi-crucible malunga neekota ezintathu.I-crucible igxothwa kwi-oven okanye kwi-oven, kwaye iziqwenga zetsimbi ezixabisekileyo zijika zibe ngamacandelo amancinci kwiqondo lokushisa elinyibilikayo kwi-alloy yabo.Ezi ngqukuva zisandul' ukudalwa zishiywe zipholile.Kamva zihlanjululwa emanzini okanye, ukuba i-soldering technique iya kusetyenziswa, ifakwe kwi-asidi.

Iigranule zobukhulu obungalinganiyo azinakuvelisa uyilo olukholisayo.Ekubeni kungenakwenzeka ukuba umkhandi wegolide enze iisphere ezihambelana ngokugqibeleleyo zobukhulu obufanayo, iigranules kufuneka zihlelwe ngaphambi kokusetyenziswa.Uluhlu lweesefu zisetyenziselwa ukuhlenga iigranules.

Uyenza njani igolide?

Ngaba inkqubo yokwenza ukudubula kwegolide kugalela nje igolide etyhidiweyo kancinane emanzini emva kokuba uyifudumeza?Okanye uzenza zonke ngaxeshanye?Yintoni injongo yokwenza igolide shot endaweni ingots ect.

Ukudutyulwa kwegolide akwenziwa ngokugalelwa kumlebe wesitya.Kufuneka ikhutshwe ngombhobho.Unokwenza elula ngokugrumba umngxuma omncinci (1/8") ezantsi kwesitya esinyibilikayo, esiya kuthi ke sibekwe phezu kwesikhongozeli sakho samanzi, netotshi idlala esityeni, ijikeleze umngxuma. igolide ekukhenkcekeni esityeni xa ikhutshelwa kwisitya sokunyibilika apho umgubo wegolide unyibilikiswa khona ngenxa yezizathu ebezisoloko zinzima kum ukuziqonda, ezithi zenze udubulo, endaweni yeecornflakes.

I-shot ikhethwa ngabo basebenzisa igolide, kuba yenza ukulinganisa inani elifunekayo libe lula.Abakhandi begolide abalumkileyo abayinyibiliki igolide eninzi ngexesha elinye, kungenjalo kunokukhokelela ekufakweni okuneziphene (ukufakwa kwegesi).

Ngokunyibilikisa kuphela isixa esifunekayo, isixa esincinci esishiyekileyo (i-sprue) sinokunyibilikiswa kunye nebhetshi elandelayo, ukuqinisekisa ukuba igolide ephinde yanyibilikiswa ayiqokeleli.

Ingxaki yokunyibilika kwegolide amaxesha ngamaxesha kukuba isiseko sesinyithi (esiqhele ubhedu, kodwa singathintelwanga kubhedu) sikhupha i-oxidize kwaye siqalise ukudala irhasi eqokelelana kwiipokotho ezincinci kwi-castings.Uninzi lwazo zonke izacholo ezisakhayo ziye zafumana la mava, kwaye zihlala ziphendula ukuba kutheni zingafuni, okanye zingakhethi ukusebenzisa igolide ebikhe yasetyenziswa ngaphambili.