Ubungakanani obubambeneyo beMetal Granulator yesiXhobo sokuGranula seGolide yeSilivere

Iiparamitha zobuGcisa

| Umzekelo No. | HS-GS2 | HS-GS3 | HS-GS4 | HS-GS5 | HS-GS6 | HS-GS8 |

| I-Voltage | 220V, 50/60Hz, isigaba esinye / 380V, 50/60Hz, isigaba se-3 | |||||

| Amandla | 8KW | 10KW | 15KW | |||

| Ubukhulu beTemp | 1500°C | |||||

| Umthamo (igolide) | 2kg | 3kg | 4kg | 5kg | 6kg | 8kg |

| Ixesha lokunyibilika | 2-3 imiz. | 3-5 imiz. | ||||

| Isicelo | Igolide, K igolide, isilivere, ubhedu kunye nezinye ialloys | |||||

| Ukubonelela ngomoya | Umoya weCompressor | |||||

| Ukuchaneka kweTemp | ±1°C | |||||

| Isibonisi sexesha | Thermocouple | |||||

| Uhlobo lokupholisa | Amanzi abandayo (athengiswa ngokwahlukeneyo) okanye Amanzi abalekayo | |||||

| Imilinganiselo | 1100*930*1240mm | |||||

| Ubunzima | Malunga. 180kg | Malunga. 200kg | ||||

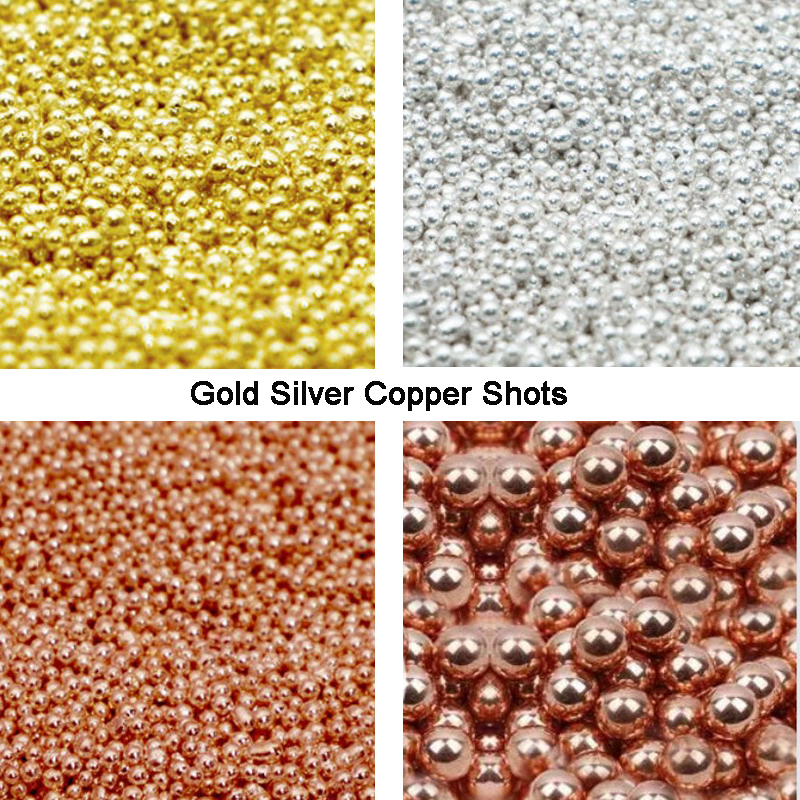

Umboniso weMveliso

Isihloko: Indima yegranulator yesinyithi kwinkqubo yokusulungekisa igolide

Ukusulungekiswa kwegolide yinkqubo enobuchule ebandakanya amanqanaba amaninzi kunye nezixhobo zokukhupha igolide esulungekileyo kwimeko yayo ekrwada. Esinye sezixhobo eziphambili zezixhobo kule nkqubo yokucoca yigranulator yesinyithi. Kule bhlog, siza kuphonononga indima yegranulator yentsimbi ekusulungekiseni igolide kunye nendlela enceda ngayo ekukhupheni igolide esulungekileyo.

Yintoni igranulator yesinyithi?

Phambi kokuba singene nzulu kwindima yegranulator yesinyithi ekusulungekiseni igolide, masiqale siqonde ukuba yintoni igranulator yesinyithi kunye nendlela esebenza ngayo. Igranulator yentsimbi ngumatshini owenzelwe ukutyumza intsimbi ekrwada ibe ngamasuntswana alinganayo, alinganayo okanye iigranule. Iqhele ukusetyenziswa kumashishini okurisayikilishwa kunye nolawulo lwenkunkuma ukusetyenzwa kwesinyithi esilahliweyo kwaye siyiguqulele kwifomu elawulekayo ukuze iqhubeke nokusebenza.

Indima yegranulator yesinyithi ekuphuculeni igolide

Ekusulungekisweni kwegolide, igranulator yesinyithi idlala indima ebalulekileyo kwinqanaba lokuqala lokulungiswa kwemathiriyeli ekrwada. Nali igalelo layo kwinkqubo yokusulungekiswa iyonke:

1. Ukunciphisa intsimbi yentsimbi

Ngexesha lenkqubo yokusulungekiswa kwegolide, iintlobo ezahlukeneyo zenkunkuma yentsimbi ziyenziwa, kubandakanywa amacandelo alahlwayo, inkunkuma ye-elektroniki kunye nezinye izinto ezinentsimbi. Ezi mathiriyeli zifuna ukuncitshiswa kobungakanani ukuze kube lula ukuqhubekeka phambili. Apha kulapho iigranulator zentsimbi zingena khona. Ityumza ngokufanelekileyo kunye neepellets zentsimbi, idala i-feedstock elawulekayo kumanyathelo okucoca alandelayo.

2. Ukwahlulwa kwezinto ezingezizo igolide

Emva kokuba intsimbi yesinyithi igranuliwe, inyathelo elilandelayo kwinkqubo yokusulungekiswa kwegolide kukwahlula izinto ezingezizo igolide kwizinto ezinegolide. Isinyithi segranular siqhubeka neenkqubo zokwahlula ezongezelelweyo ezifana nokwahlukana kwamagnetic kunye nokwahlukana okusekwe kuxinaniso ukwahlula izinto eziqulathe igolide kuyo yonke inkunkuma yesinyithi. Ubungakanani obufanayo kunye nokumila kwesinyithi segranular kunceda ezi ndlela zokwahlula, okwenza inkqubo isebenze ngakumbi.

3. Ukuphucula indawo engaphezulu yokulungiswa kweekhemikhali

Emva kokuba izinto ezingezizo igolide zahlulwe, amacandelo egolide anegranular aphathwa ngokwekhemikhali ukuze akhuphe igolide esulungekileyo. Ifom yesuntswana lemathiriyeli ibonelela ngomphezulu wendawo omkhulu, ovumela iikhemikhali ukuba zingene kwaye zisabele ngamasuntswana egolide ngokufanelekileyo. Oku kukhokelela ekusebenzeni okuphezulu kokutsalwa kunye nenkqubo yokucoca ngokucokisekileyo.

4. Ukuphucula iinkqubo zokunyibilikisa nokuphosa

Nje ukuba igolide ikhutshiwe kwisixhobo segranular, iye isetyenzwe ngokunyibilika kunye nokuphoswa ukuze yenze iingots zegolide okanye ezinye iimilo ezinqwenelekayo. Ifomu yegranular yegolide iququzelela inkqubo yokunyibilika kuba iyatshisa kwaye inyibilikisa izinto ngokulinganayo. Oku kuvelisa iimveliso zegolide ezikumgangatho ophezulu kunye namanqanaba angaguqukiyo okucoceka.

Ngokubanzi, iigranulator zesinyithi zidlala indima ephambili kumanqanaba okuqala okusulungekiswa kwegolide ngokulungiselela imathiriyeli ekrwada ukuze iqhubeke nokusebenza, ukukhuthaza ukwahlula okusebenzayo kwezinto ezingezizo igolide, ukonyusa indawo yomphezulu wokulungiswa kweekhemikhali, kunye nokuphucula iinkqubo zokunyibilikisa nokuphosa.

Ukubaluleka kweenkqubo ezisebenzayo zokusulungekiswa kwegolide

Inkqubo esebenzayo yokusulungekiswa kwegolide ibalulekile ekuqinisekiseni ubunyulu kunye nomgangatho wemveliso yegolide yokugqibela. Enoba isetyenziselwa ukwenza izacholo, iinjongo zotyalo-mali, okanye kwimizi-mveliso, igolide esulungekileyo ixatyiswa kakhulu yaye ifunwa kakhulu. Ngoko ke, indima yezixhobo ezifana ne-pelletizers zetsimbi ekucoceni igolide ekucocekeni okufunekayo kunye nomgangatho awukwazi ukugqithiswa.

Ukongeza kwimiba yobugcisa, inkqubo esebenzayo yokusulungekiswa kwegolide ikwanegalelo kuzinzo lokusingqongileyo. Ngokulawula ngokukuko nangokusetyenzwa kwenkunkuma yesinyithi, kubandakanywa inkunkuma yombane kunye nezixhobo ezilahliweyo, ishishini lokusulungekisa linokunciphisa impembelelo yokusingqongileyo yokomba igolide kwaye libe negalelo kulawulo lwemithombo ezinzileyo.

ukuququmbela

Isishwankathelo, iigranulator zentsimbi zidlala indima ebalulekileyo kwinkqubo yokusulungekiswa kwegolide, kubandakanya nokulungisa izinto ezingasetyenziswanga, ukuququzelela ukwahlula okusebenzayo, ukomeleza unyango lweekhemikhali, kunye nokuphucula iinkqubo zokunyibilikisa nokuphosa. Igalelo layo ekusebenzeni kakuhle kunye nomgangatho wokusulungekiswa kwegolide alinakungahoywa. Njengoko imfuno yegolide esulungekileyo iqhubeka nokukhula, iinkqubo ezisebenzayo zokusulungekisa, ezixhaswa zizixhobo eziphambili ezinjengeegranulator zentsimbi, ziya zisibaluleka ngakumbi ukuhlangabezana neemfuno zeshishini lemveliso yegolide ekumgangatho ophezulu.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur