Oomatshini abaQhuba ngokuQhutywayo

Umgaqo womsebenzi wohlobo oluqhelekileyo oluqhubekayo lwemishini yokuphosa isekelwe kwiingcamango ezifanayo njengoomatshini bethu bokuphosa uxinzelelo lwe-vacuum. Esikhundleni sokuzalisa izinto ezimanzi kwi-flask unokuvelisa / ukudweba iphepha, ucingo, intonga, okanye ityhubhu ngokusebenzisa i-graphite mold. Konke oku kwenzeka ngaphandle kwamaqamza omoya okanye i-porosity ehlayo. I-vacuum kunye ne-vacuum ephezulu eqhubekayo yomatshini yokuphosa isetyenziselwa ukwenza iingcingo ezikumgangatho ophezulu ezifana ne-bonding wire, i-semiconductor, intsimi ye-aerospace.

-

I-Hasung-High Vacuum eZixhobisa ngokuNgqongileyo kwiZinyithi ezixabisekileyo

Iintsimbi ezisebenzayo:izinto zentsimbi ezifana negolide, K igolide, isilivere, ubhedu, kunye nengxubevange yazo

Amashishini ezicelo:izinto zocingo ezibophelelayo, ubucwebe bezacholo, ukusetyenzwa kwentsimbi exabisekileyo, iilebhu zeyunivesithi kunye nezinye iinkalo ezinxulumeneyo

Iinzuzo zemveliso:

1. I-vacuum ephezulu (6.67 × 10-3pa), i-vacuum melting ephezulu, ubuninzi bemveliso, i-oksijeni ephantsi, i-pores, ifanelekile ukuvelisa i-high quality bonding wire;

2. I-Anti oxidation, i-inert yokukhusela igesi yokucoca, ukusombulula ingxaki ye-alloy oxidation;

3. Umbala ofanayo, iindlela ze-electromagnetic kunye nezishukumisayo zomzimba zenza umbala we-alloy ufane ngakumbi;

4. Imveliso egqityiweyo inomgangatho ogudileyo kwaye ithatha uyilo lokutsalwa phantsi. Ivili lokutsala liye lafumana unyango olukhethekileyo, kwaye imveliso egqityiweyo ayinayo umonakalo ebusweni kunye nomgangatho ococekileyo;

5. Ulawulo oluchanekileyo lweqondo lokushisa ± 1 ℃, usebenzisa iimitha zokulawula ubushushu kunye nenkqubo ehlakaniphile yokulawula ubushushu bePID, kunye nokwahlukana kobushushu be-± 1 ℃;

6. I-7-intshi yesikrini esigcweleyo sombala wesikrini, kulula ngakumbi ukujonga / ukuchukumisa, inkqubo entsha, i-interface ye-UI elula, kulula ukuyisebenzisa ngokuchukumisa nje enye;

7. Ukhuseleko oluninzi, ukhuseleko oluninzi, ukuxhalaba ukusetyenziswa kwasimahla

-

Iintsimbi ezixabisekileyo eziNxibelele ziVacuum eziQhubekekayo zokuCasa umatshini

Vacuum ethe tyaba eqhubekayo umatshini wokugalela izinto ezilungileyo

1. Ukuphucula umgangatho wemveliso

2. Ulawulo lwenkqubo oluphuculweyo

3. Ukwandiswa kweMveliso

4. Ukusebenza kakuhle kwamandla

Iimpawu ze-horizontal vacuum umatshini oqhubekayo wokuphosa

1. Uyilo lokuSasa oluthe tye

2. Igumbi lokufunxa

3. Inkqubo yokupholisa

4. Ukuzenzekela kunye nenkqubo yokulawula

5. Umthamo omkhulu wokunyibilika

6. Imveliso yokuphosa esemgangathweni

-

Umatshini oqhubekayo wokuphosa weGolide yeSilver Copper Alloy 20kg 30kg 50kg 100kg

1.Kamsinya nje isilivere yegolide strip wire tube intongaumatshini wokuphosa oqhubekayokuba izacholo yaqaliswa kwimarike, ifumene ingxelo entle kubathengi abaninzi, abathi olu hlobo lwemveliso lunokusombulula ngempumelelo iimfuno zabo.Ngaphezu koko, imveliso isetyenziswa ngokubanzi kwiMetal Casting.

I-2.Umatshini wokuCasa oqhubekayo wokwenza i-Rod Strip Pipe kunye ne-20kg 30kg 50kg 100kg xa kuthelekiswa neemveliso ezifanayo kwimarike, ineenzuzo ezibalaseleyo ezingenakulinganiswa malunga nokusebenza, umgangatho, ukubonakala, njl., kwaye uyonwabela igama elihle kwimarike.Hasung ishwankathela iziphene zeemveliso ezidlulileyo, kwaye ngokuqhubekayo iphucula. Iinkcukacha zoomatshini oqhubekayo wokuphosa wokwenza umbhobho we-Rod Strip kunye ne-20kg 30kg 50kg 100kg unokwenziwa ngokwezifiso ngokweemfuno zakho.

-

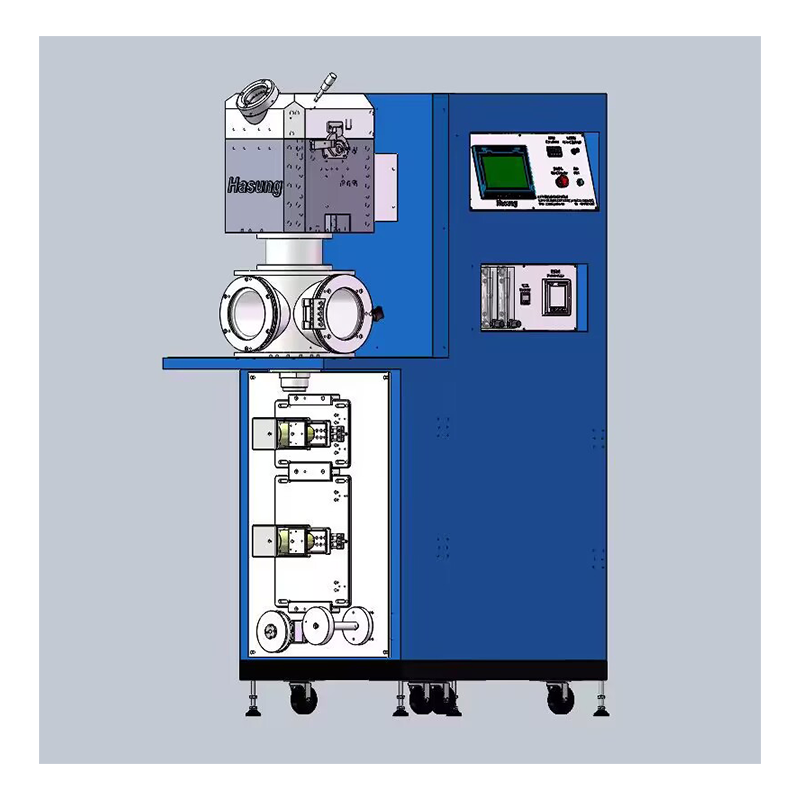

Umatshini weVacuum oPhezulu oqhubekayo wokuCasa kwiZixhobo eziNtsha zokuCasa iBonding yeGolide yeSilver Copper Wire

Ukuphoswa kwezinto zombane ezifana ne-bond alloy silver copper wire kunye ne-high-purity special wire Uyilo lwale nkqubo yezixhobo lusekelwe kwiimfuno zokwenene zeprojekthi kunye nenkqubo, kwaye isebenzisa ngokupheleleyo iteknoloji yanamhlanje ephezulu.

1. Yamkela iteknoloji yaseJamani yokufudumeza i-high-frequency, i-automatic frequency tracking kunye neteknoloji yokukhusela ezininzi, ezinokunyibilika ngexesha elifutshane, ukugcina amandla kunye nokusebenza ngokufanelekileyo.

2. Uhlobo oluvaliweyo + igumbi elinyibilikayo lokukhusela igesi e-inert linokuthintela i-oxidation yezinto ezibunjiweyo ezityhidiweyo kunye nokuxuba ukungcola. Esi sixhobo sifanelekile ukuphosa izinto zetsimbi ezicocekileyo okanye isinyithi esine-oxidized ngokulula.

3. Sebenzisa igesi evaliweyo + engasebenziyo ukukhusela igumbi elinyibilikayo. Xa unyibilika kwindawo yegesi engasebenziyo, ilahleko ye-oxidation ye-carbon mold iphantse ingabikho.

4. Ngomsebenzi wokuvuselela i-electromagnetic + ukuvuselela oomatshini phantsi kokukhuselwa kwegesi ye-inert, akukho ulwahlulo lombala.

5. Ukusebenzisa i-Mistake Proofing (i-anti-fool) inkqubo yokulawula ngokuzenzekelayo, ukusebenza kukulungele ngakumbi.

6. Ukusebenzisa inkqubo yokulawula ubushushu be-PID, ubushushu buchaneke ngakumbi (± 1 ° C).

7. HVCC uthotho high vacuum isixhobo eqhubekayo ukugalela ziphuhliswe ngokuzimeleyo kwaye wenziwe, kunye netekhnoloji ephucukileyo, esetyenziselwa ukugalela ngokuqhubekayo igolide ubusulungekileyo eliphezulu, isilivere, ubhedu kunye nezinye ingxubevange.

8. Esi sixhobo sisebenzisa inkqubo yokulawula inkqubo ye-Mitsubishi PLC, i-SMC pneumatic kunye ne-Panasonic servo motor drive kunye namanye amacandelo e-brand brand yasekhaya nangaphandle.

9. Ukunyibilika kwindawo evaliweyo yokukhusela igesi ye-inert encibilikayo, ukondla kabini, ukuvuselela i-electromagnetic, ukuvuselela oomatshini, ifriji, ukwenzela ukuba imveliso ibe neempawu zokungabikho kwe-oxidation, ilahleko ephantsi, i-porosity, akukho ukwahlula kombala, kunye nokubonakala okuhle.

10. Uhlobo lweVacuum: Ivacuum ephezulu.

-

Umatshini wokuGutyula oqhubekayo weGolide yeSilver Copper Alloy

Ivacuum eyodwa eqhubekayo inkqubo yokuphosa

Ngowona mgangatho uphezulu wemathiriyeli egqityiweyo:

Ukunciphisa umngcipheko we-oxidation ngexesha lokunyibilika kunye nexesha lokudweba, sigxininise ekuphepheni ukudibanisa ne-oxygen kunye nokunciphisa ngokukhawuleza ubushushu bezinto ezitsaliweyo zetsimbi.

Iimpawu zokuthintela ukunxibelelana kwe-oxygen:

1. Inkqubo yegesi engasebenziyo yegumbi lokunyibilika

2. Inkqubo ye-vacuum yegumbi lokunyibilika - ifumaneka ngokukodwa kwi-Hasung vacuum eqhubekayo yomatshini wokuphosa (uchungechunge lweVCC)

3. Ukugungxulwa kwerhasi engasebenziyo kwidayisi

4. Umlinganiselo weqondo lobushushu bokufa

5. Inkqubo yokupholisa yesibini eyongezelelweyo

6. Yonke le milinganiselo ifanelekile ngokukodwa kwii-alloys ezinobhedu ezifana negolide ebomvu okanye isilivere njengoko ezi zixhobo zivame uku-oxidise ngokulula.Inkqubo yokuzoba kunye nemeko inokujongwa ngokulula ngokujonga iifestile.

Izidanga zevacuum zinokuhambelana nesicelo sabathengi.

-

Umatshini oqhubekayo wokuphosa weGolide yeSilver Copper Alloy

Uyilo lwale nkqubo yezixhobo lusekwe kwiimfuno zokwenyani zeprojekthi kunye nenkqubo, kusetyenziswa itekhnoloji yobuchwepheshe bale mihla.

1. Ukusebenzisa iteknoloji yaseJamani yokufudumeza i-high-frequency, ukulandelela i-frequency ngokuzenzekelayo kunye neeteknoloji ezininzi zokukhusela, inokunyibilika ngexesha elifutshane, ukugcinwa kwamandla kunye nokukhuselwa kwendalo, kunye nokusebenza kakuhle komsebenzi.

2. Uhlobo oluvaliweyo + igumbi elinyibilikayo lokukhusela igesi e-inert linokuthintela i-oxidation yezinto ezibunjiweyo ezityhidiweyo kunye nokuthintela ukuxutywa kokungcola. Esi sixhobo sifanelekile ukuphosa izinto zetsimbi ezicocekileyo okanye isinyithi esine-oxidized ngokulula.

3. Ukusebenzisa igumbi elinyibilikayo lokukhusela igesi elivaliweyo + elingenayo, ukunyibilika kunye nokucoca kwenziwa ngexesha elifanayo, ixesha liqikelelwe, kwaye ukusebenza kakuhle kwemveliso kuphuculwe kakhulu.

4. Ukunyibilika kwindawo yegesi ye-inert, ukulahleka kwe-oxidation ye-carbon crucible phantse iyinto engafanelekanga.

5. Ngomsebenzi wokuvuselela i-electromagnetic phantsi kokhuseleko lwegesi ye-inert, akukho ulwahlulo lombala.

6. Yamkela i-Mistake Proofing (i-anti-fool) inkqubo yokulawula ngokuzenzekelayo, ekulula ukuyisebenzisa.

7. Ukusebenzisa inkqubo yokulawula ubushushu be-PID, ubushushu buchaneke ngakumbi (± 1 ° C). Uchungechunge lwe-HS-CC oluqhubekayo lwezixhobo zokulahla luphuhliswa ngokuzimeleyo kwaye lwenziwe ngeteknoloji ephucukileyo kwaye lunikezelwe ekunyibilikeni nasekuphoseni igolide, isilivere, ubhedu kunye nezinye iintambo ze-alloys, iintonga, amaphepha, imibhobho, njl.

8. Esi sixhobo sisebenzisa inkqubo yokulawula inkqubo ye-Mitsubishi PLC, i-SMC pneumatic kunye ne-Panasonic servo motor drive kunye namanye amacandelo e-brand eyaziwayo ekhaya nakwamanye amazwe.

9. Ukunyibilika, ukunyanzeliswa kwe-electromagnetic, kunye nefriji kwindawo evaliweyo yokukhusela igesi ye-inert, ukwenzela ukuba imveliso ibe neempawu zokungabi ne-oxidation, ilahleko ephantsi, i-pores, akukho ukwahlula kombala, kunye nokubonakala okuhle.

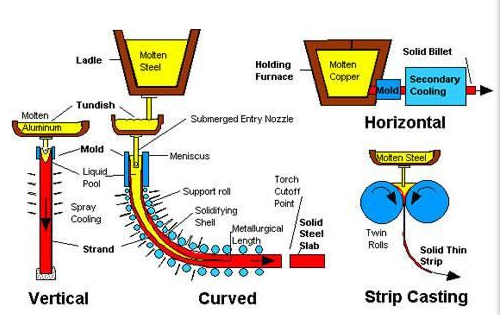

Yintoni ukuphosa okuqhubekayo, kwenziwa ntoni, yintoni inzuzo?

Inkqubo eqhubekayo yokuphosa yindlela esebenzayo kakhulu yokuvelisa iimveliso ezigqityiweyo njengemivalo, iiprofayili, ii-slabs, imicu kunye neetyhubhu ezenziwe ngegolide, isilivere kunye neentsimbi ezingenayo i-ferrous ezifana nobhedu, i-aluminium kunye ne-alloys.

Nokuba kukho iindlela ezahlukeneyo zokuphosa eziqhubekayo, akukho mahluko ubalulekileyo ekujuleni igolide, isilivere, ubhedu okanye ialloys. Umahluko obalulekileyo ngamaqondo obushushu okuphosa aqala malunga ne-1000 °C kwimeko yesilivere okanye ubhedu ukuya kwi-1100 °C kwimeko yegolide okanye ezinye ialloys. Isinyithi esinyibilikisiweyo sihlala siphoswa kwisitya sokugcina esibizwa ngokuba yi-ladle kwaye ihamba ukusuka apho ukuya kubumba lokuphosa oluthe nkqo okanye oluthe tye olunesiphelo esivulekileyo. Ngelixa ihamba ngokubumba, epholileyo nge-crystallizer, ubunzima bolwelo buthatha iphrofayili yesikhunta, buqala ukuqina kumphezulu walo kwaye bushiye ukubumba kwi-strand e-semi-solid. Kwangaxeshanye, inyibilika entsha isoloko inikezelwa kwi-mold kwizinga elifanayo ukugcina kunye ne-strand eqinisayo eshiya ukubumba. Umcu uphinda upholiswe ngenkqubo yokutshiza ngamanzi. Ngokusetyenziswa kokupholisa okuqinisiweyo kunokwenzeka ukunyusa isantya sekristallisation kunye nokuvelisa kwi-strand i-homogeneous, i-fine-grained structure enika i-semi-finished product properties zobuchwepheshe. Intambo eqinisiweyo iyalungiswa kwaye isikwe ubude obufunwayo ngeeshears okanye itotshi yokusika.

Amacandelo anokusetyenzwa ngakumbi kwimisebenzi elandelayo yokuqengqeleka kumgca wokufumana imivalo, iintonga, iibhilidi ze-extrusion (ezingenanto), ii-slabs okanye ezinye iimveliso ezigqityiweyo kwimilinganiselo eyahlukeneyo.

Imbali yosasazo oluqhubekayo

Iinzame zokuqala zokuphosa isinyithi kwinkqubo eqhubekayo zenziwa phakathi kwenkulungwane ye-19. Ngomnyaka we-1857, uSir Henry Bessemer (1813-1898) wafumana ilungelo elilodwa lomenzi wokuphosa isinyithi phakathi kweerola ezimbini ezijikelezayo zokwenza amacwecwe esinyithi. Kodwa ngelo xesha le ndlela yahlala ingahoywanga. Inkqubela phambili eqinisekileyo yenziwa ukusukela ngo-1930 ukuya phambili ngobuchule beJunghans-Rossi bokuqhubeka bephosa ukukhanya kunye neentsimbi ezinzima. Ngokuphathelele intsimbi, inkqubo eqhubekayo yokuphosa yaphuhliswa ngo-1950, ngaphambi (nasemva koko) ukuba intsimbi yagalelwa kwisingundo esimileyo ukwenza 'iingots'.

Ukuphoswa ngokuqhubekayo kwentonga ye-non-ferrous yenziwe yinkqubo yeProperzi, ephuhliswe ngu-Ilario Properzi (1897-1976), umsunguli we-Continuus-Properzi inkampani.

Iingenelo zokusasa rhoqo

Ukwenziwa ngokuqhubekayo yeyona ndlela ifanelekileyo yokuvelisa iimveliso ezigqityiweyo zobukhulu obude kwaye zenza ukuba kuveliswe ubungakanani obukhulu ngexesha elifutshane. I-microstructure yeemveliso ilinganayo. Xa kuthelekiswa nokuphosa kwiziko lokubumba, ukuphosa okuqhubekayo kuqoqosho ngakumbi malunga nokusetyenziswa kwamandla kwaye kunciphisa inkunkuma encinci. Ngaphezu koko, iipropati zeemveliso ziyakwazi ukuguqulwa ngokulula ngokutshintsha iiparamitha zokuphosa. Njengoko yonke imisebenzi inokuthi yenziwe ngokuzenzekelayo kwaye ilawulwe, ukuphosa okuqhubekayo kunika amathuba amaninzi okulungelelanisa imveliso ngokuguquguqukayo kwaye ngokukhawuleza kwiimfuno eziguqukayo zemarike kunye nokudibanisa kunye ne-digitization (Industrie 4.0) iteknoloji.