I-Hasung-High Vacuum eZixhobisa ngokuNgqongileyo kwiZinyithi ezixabisekileyo

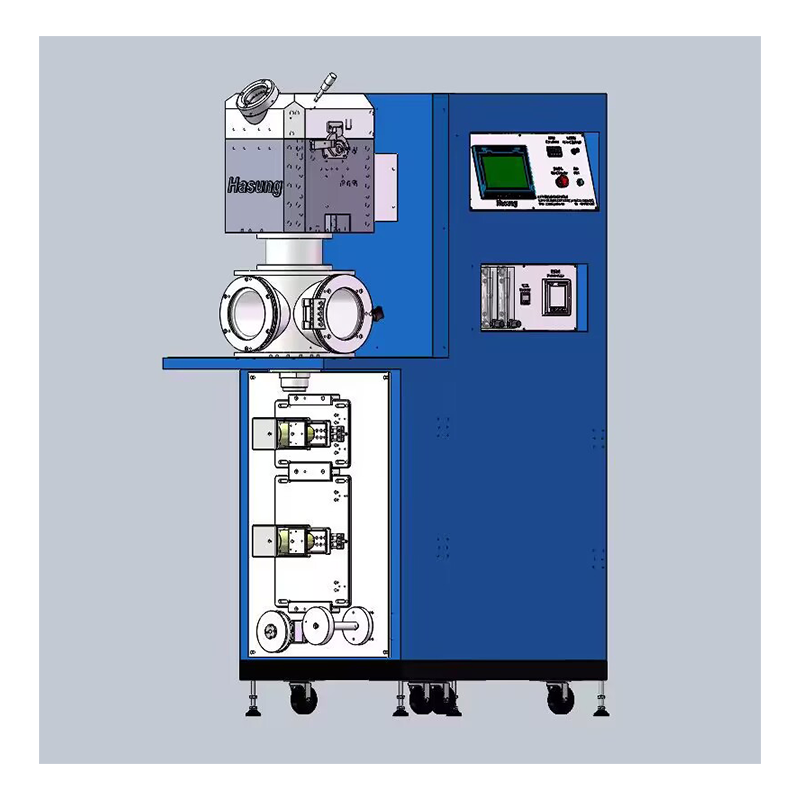

1, Inkcazelo yeZixhobo:

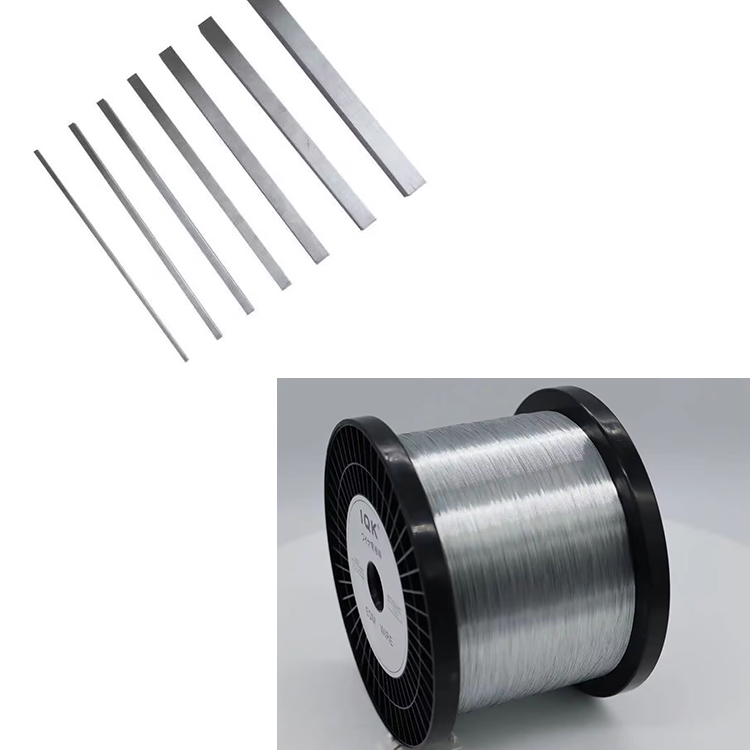

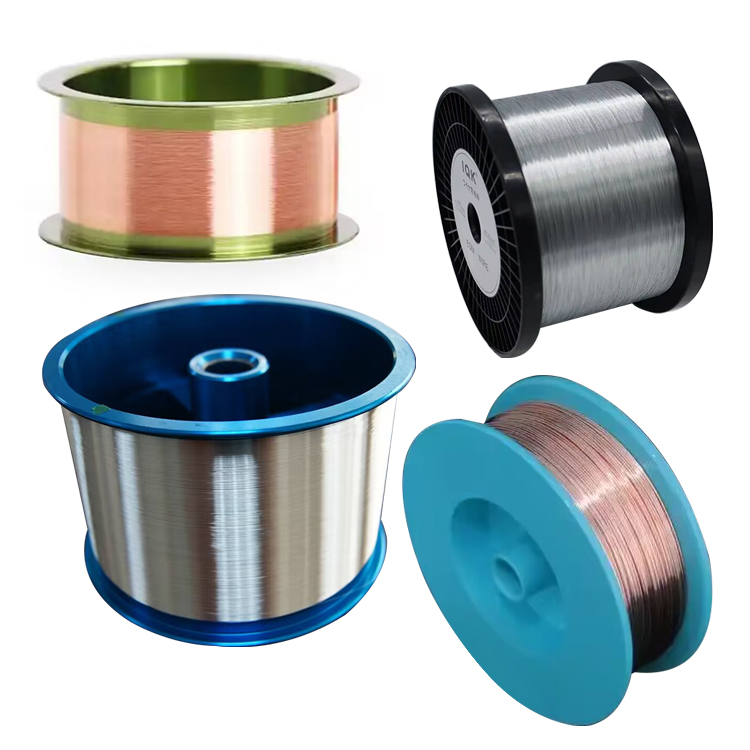

1. Esi sixhobo sisetyenziselwa ukuphosa ngokuqhubekayo imivalo yobhedu yekristale enye, imivalo yesilivere yekristale enye, kunye nemivalo yegolide yekristale enye, kwaye ingasetyenziselwa ukuveliswa okuqhubekayo kwezinye izinyithi kunye nealloys.

2. Esi sixhobo ngumzimba wesithando somlilo. Izinto eziluhlaza, i-crucible, kunye ne-crystallizer zifakwe kwisigqubuthelo somlilo esivulwe ukusuka phezulu, kwaye intonga ye-crystallization yesikhokelo ibekwe kwindawo engezantsi yomzimba wesithando somlilo. Okokuqala, i-crystal ikhutshwe kwi-melt ngobude obuthile ngokusebenzisa intonga ye-crystallization yesikhokelo, kwaye ke intonga ye-crystal igxininiswe kumatshini ojikelezayo wokudweba kunye nokuqokelela.

3. Esi sixhobo samkela isikrini sokuthintela ngokupheleleyo inkqubo yokulawula ngokuzenzekelayo kunye nezixhobo ezininzi zokubeka iliso ukulawula ngokuchanekileyo ukushisa kwesithando somlilo kunye ne-crystallizer, ukufezekisa iimeko ezizinzileyo zexesha elide ezifunekayo ekukhuleni kwekristale; Izenzo ezininzi zokukhusela zingenziwa ngokusebenzisa izixhobo zokubeka iliso, ezifana nokuvuza kwezinto ezibangelwa ukushisa okuphezulu kwesithando somlilo, i-vacuum eyaneleyo, amanzi phantsi koxinzelelo okanye ukunqongophala, njl njl. Isixhobo silula ukusebenza, kunye neeparitha eziphambili ezisetyenzisiweyo ziquka ukushisa kwesithando somlilo, ukushisa kwesithando somlilo. Amacandelo aphezulu, aphakathi, kunye nasezantsi ekristallizer, isantya sangaphambili sokutsala, isantya sokutsala ikristale (kunye nemodi ye-intshi, oku kuthetha ukutsala ixesha elithile kunye nokuyeka ixesha elithile. ixesha), kunye neendidi ezahlukeneyo ze-alam.

I-Hasung yeNtsimbi exabisekileyo iZizenzekela ngokuGqibeleleyo ngokuQhubekekayo ngokuCasa umatshini

2, Iiparamitha eziphambili zobugcisa besixhobo:

1. Uhlobo: Ithe nkqo, ulawulo oluzenzekelayo, ukufudumeza okuzenzekelayo.

2. Umbane opheleleyo wokunikezelwa kwamandla: isigaba sesithathu se-380V, i-50Hz isigaba sesithathu

3. Amandla okufudumeza: 20KW

4. Indlela yokufudumeza: Ukufudumeza ngokungenisa (akukho ngxolo)

5. Umthamo: 8kg (igolide)

6. Ixesha lokunyibilika: 3-6 imizuzu

7. Ubushushu obuninzi: 1600 degrees Celsius

6. Intonga yobhedu ububanzi: 6-10m

7. Isidanga seVacuum: Isimo esibandayo<6 67× 10-3Pa

8. Ubushushu: 1600 ℃

9. Isantya sokutsala intonga yobhedu: 100-1500mm/min (enokulungiswa)

10. Iintsimbi ezikhatywayo: igolide, isilivere, ubhedu, kunye nemathiriyeli yealloyi.

11. Indlela yokupholisa: Ukupholisa amanzi (ubushushu bamanzi buyi-18-26 ngokukaCelsius)

12. Imo yokulawula: Siemens PLC + touch screen control smart

13. Ubungakanani besixhobo: 2100 * 1280 * 1950mm

14. Ubunzima: Malunga ne-1500kg. Vacuum ephezulu: malunga ne-550kg.

3, Inkcazo yesakhiwo esingundoqo:

1. Umzimba wesithando somlilo: I-furnace body ithatha i-vertical double-layer-cooled water-cooled structure. Isigqubuthelo sesithando somlilo sinokuvulwa ukuze kube lula ukufaka ii-crucibles, i-crystallizers, kunye nezinto eziluhlaza. Kukho ifestile yokujonga kwindawo ephezulu yesithando somlilo, enokuqwalasela imeko yezinto ezityhidiweyo ngexesha lokunyibilika. I-electrode induction flanges kunye ne-vacuum pipeline flanges zicwangciswe ngokulinganayo kwiindawo ezahlukeneyo zokuphakama kumbindi wesithando somlilo ukwazisa i-electrode joints kunye nokudibanisa kunye neyunithi ye-vacuum. Isitya esisezantsi sesithando somlilo sixhotyiswe ngesakhelo senkxaso ye-crucible, ekwasebenza njengemfumba esisigxina ukulungisa ngokuchanekileyo indawo ye-crystallizer, ukuqinisekisa ukuba umgodi ophakathi we-crystallizer ugxininise kunye nomjelo wokutywinwa kwisitya esisezantsi somlilo. Ngaphandle koko, intonga ye-crystallization yesikhokelo ayiyi kukwazi ukungena ngaphakathi kwe-crystallizer ngokusebenzisa umjelo wokutywinwa. Kukho amakhonkco amathathu apholileyo ngamanzi kwisakhelo senkxaso, ehambelana nendawo ephezulu, ephakathi, kunye nangaphantsi kwe-crystallizer. Ubushushu benxalenye nganye yekristali ilawulwa ngokuchanekileyo ngokulawula izinga lokuhamba kwamanzi okupholisa. Kukho ii-thermocouples ezine kwisakhelo sokuxhasa, ezisetyenziselwa ukulinganisa ubushushu beendawo eziphezulu, eziphakathi, kunye nezisezantsi ze-crucible kunye ne-crystallizer, ngokulandelanayo. I-interface phakathi kwe-thermocouples kunye nangaphandle kwesithando somlilo ibekwe kwi-plate ephantsi yomlilo. Isitya sokukhupha singabekwa phantsi kwesakhelo sokuxhasa ukukhusela ubushushu obunyibilikayo ukuba buhambe ngokuthe ngqo kwi-cleaner kwaye bubangele umonakalo kumzimba wesithando somlilo. Kukwakho negumbi lokufunxa elirhabaxa elinokususwa kwindawo esembindini kwipleyiti esezantsi yeziko. Ngaphantsi kwegumbi lokucoca elirhabaxa kukho igumbi leglasi yendalo enokuthi idityaniswe ne-anti-oxidation agent ukuze kuphuculwe ukutywinwa kwevacuum yocingo olucolekileyo. Izinto eziphathekayo zinokufikelela kwimpembelelo ye-anti oxidation kumphezulu wentonga yobhedu ngokongeza i-agent echasene ne-oxidation kwindawo yeglasi ye-organic.

2. I-Crucible kunye ne-Crystallizer: I-crucible kunye ne-crystallizer yenziwe nge-graphite ephezulu. I-bottom of the crucible is conical kwaye ixhunywe kwi-crystallizer ngokusebenzisa imicu.

3. Inkqubo yokufunxa:

1. Impompo yeengcambu

2. Ivalve ye-vacuum ye-vacuum ephezulu yepneumatic

3. Ivalve ye-vacuum yokunyuka kwamaxabiso e-Electromagnetic

4. Igeyiji yevacuum ephezulu

5. Igeyiji yevacuum ephantsi

6. Umzimba wesithando somlilo

7. Ivalve yevacuum ephezulu yomoya

8. Umgibe obandayo

9. Impompo yokusasaza

4. Indlela yokuzoba kunye nokujija: Ukusatywa okuqhubekayo kweentsimbi zobhedu kubandakanya amavili esikhokelo, izikrufu ezichanekileyo, izikhokelo zemigca, kunye neendlela zokujija. Ivili lesikhokelo lidlala indima ekhokelayo kunye nokubeka indawo, kwaye into yokuqala intonga yobhedu idlula xa iphuma esithandweni somlilo yivili lesikhokelo. Intonga ye-crystallization yesikhokelo igxininiswe kwi-screw echanekileyo kunye nesixhobo sesikhokelo somgca. Intonga yobhedu itsalwa kuqala kumzimba wesithando somlilo (itsalwe ngaphambili) ngentshukumo yomgca wentonga yecrystallization. Xa intonga yobhedu idlula kwivili lesikhokelo kwaye inobude obuthile, ukuxhamla kunye nentonga ye-crystallization yesikhokelo inokunqunyulwa. Emva koko igxininiswe kumatshini ojikelezayo kwaye iyaqhubeka nokuzoba intonga yobhedu ngokujikeleza komatshini ojikelezayo. I-servo motor ilawula intshukumo yomgca kunye nokujikeleza komatshini ojikelezayo, onokulawula ngokuchanekileyo isantya esiqhubekayo sokuphosa intonga yobhedu.

5. Inkqubo yamandla ye-ultrasonic power supply ithatha i-IGBT yaseJamani, enomsindo ophantsi kunye nokugcina amandla. Iqula lisebenzisa izixhobo zokulawula ubushushu ukufudumeza okucwangcisiweyo. Uyilo lwenkqubo yombane

Kukho i-overcurrent, impendulo ye-overvoltage kunye neesekethe zokukhusela.

6. Inkqubo yokulawula: Esi sixhobo samkela isikrini sokuthintela ngokupheleleyo inkqubo yokulawula ngokuzenzekelayo kunye nezixhobo ezininzi zokubeka iliso ukulawula ngokuchanekileyo ukushisa kwesithando somlilo kunye ne-crystallizer, ukufezekisa iimeko ezizinzileyo zexesha elide ezifunekayo kwi-copper rod casting casting; Izenzo ezininzi zokukhusela zingenziwa ngokusebenzisa izixhobo zokubeka iliso, ezifana nokuvuza kwezinto ezibangelwa ukushisa okuphezulu kwesithando somlilo, i-vacuum eyaneleyo, amanzi phantsi koxinzelelo okanye ukunqongophala, njl njl. Isixhobo silula ukusebenza kwaye iiparitha eziphambili zisetyenzisiwe.

Kukho iqondo lobushushu lesithando somlilo, iqondo lobushushu eliphezulu, eliphakathi, kunye nasezantsi iindawo zekristali, isantya sangaphambili sokutsala, kunye nesantya sokukhula kwekristale.

Kwaye amaxabiso ahlukeneyo e-alamu. Emva kokumisela iiparitha ezahlukeneyo, kwinkqubo yokuvelisa intonga yobhedu eqhubekayo, okoko nje ukhuseleko luqinisekisiwe.

Beka intonga ye-crystallization yesikhokelo, ubeke izinto eziluhlaza, uvale umnyango wesithando somlilo, unqumle uxhulumaniso phakathi kwentonga yobhedu kunye nentonga yesikhokelo se-crystallization, kwaye uyidibanise kumatshini wokuvala.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur