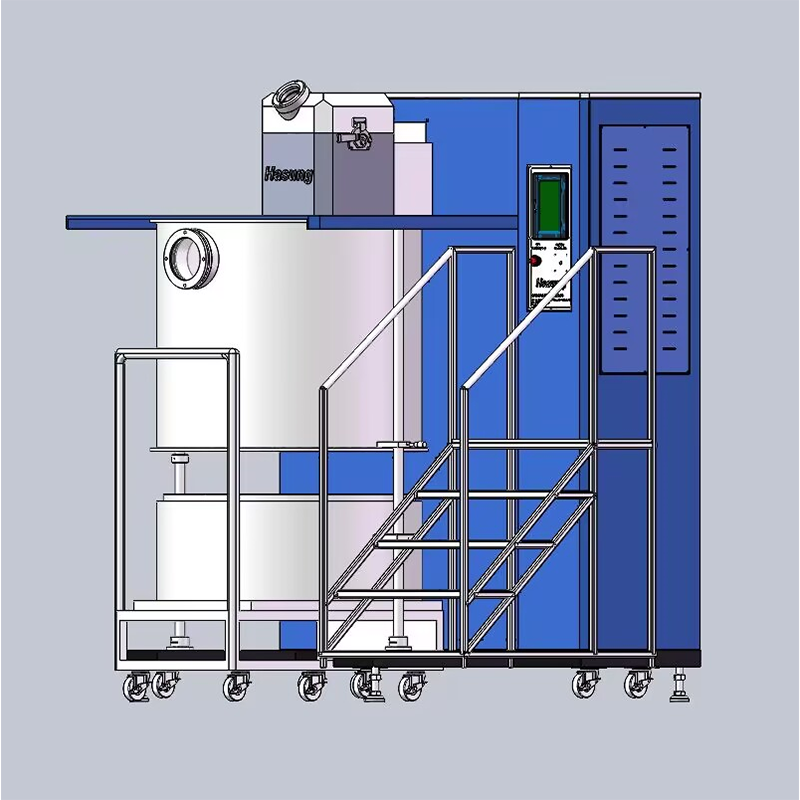

Metal Powder Water Atomizer For Precious Metal Platinum Palladium Steel

IParameter yobuGcisa

| Umzekelo No. | HS-MI4 | HS-MI10 | HS-MI20 |

| I-Voltage | 380V 3 Izigaba, 50/60Hz | ||

| Ukunikezwa Amandla | 15KW | 25KW | 40KW |

| Ubukhulu beTemp. | 2100°C | ||

| Ixesha lokunyibilika | 3-5 Imiz. | 5-8 Imiz. | 5-8 Imiz. |

| Ukugalela iinkozo | 80#-200#-400#-500# | ||

| Ukuchaneka kweTemp | ±1°C | ||

| Umthamo (Pt) | 4kg | 10kg | 30kg |

| Impompo yokufunxa | (ukhetho) | ||

| Isicelo | Igolide, isilivere, ubhedu, ialloys; Iplatinam(Ngokuzikhethela) | ||

| Indlela yokusebenza | Ukusebenza okungundoqo okukodwa ukugqiba yonke inkqubo, inkqubo ye-POKA YOKE engenangqondo | ||

| Inkqubo yokulawula | I-Taiwan Weinview + Siemens PLC inkqubo yokulawula ekrelekrele | ||

| Irhasi yokuKhusela | Nitrogen / Argon | ||

| Uhlobo lokupholisa | Isibambisi samanzi (Ithengiswa ngokwahlukeneyo) | ||

| Imilinganiselo | 1180x1070x1925mm | 1180x1070x1925mm | 3575*3500*4160mm |

| Ubunzima | malunga. 460kg | malunga. 560kg | malunga. 2150kg |

| Impompo yamanzi yoxinzelelo oluphezulu | ifakiwe | ||

Iimbonakalo

I-HS-MI1 yintsapho yee-atomizers zamanzi ezenzelwe ukuvelisa i-powders yensimbi yesimo esingaqhelekanga, ukuba isetyenziswe kwimizi-mveliso, imichiza, i-soldering paste, i-resin filters, i-MIM kunye nezicelo ze-sintering.

I-atomizer isekelwe kwisithando somlilo se-induction, sisebenza kwigumbi elivaliweyo phantsi kwe-atmosphere ekhuselayo, apho isinyithi esityhidiweyo sigalelwa kwaye sibethelwe yijethi yamanzi oxinzelelo oluphezulu, ukuvelisa i-powders ecocekileyo kunye ne-deoxidized.

Ukufudumeza kwe-induction kuqinisekisa i-homogenization enhle kakhulu ye-melt enkosi kwisenzo sokuvuselela magnetic ngexesha lesigaba esityhidiweyo.

Iyunithi yokufa ixhotyiswe ngejenereyitha eyongezelelweyo, evumela ukuqalisa kwakhona umjikelo kwimeko yokuphazamiseka komjikelezo.

Ukulandela amanyathelo okunyibilika kunye ne-homogenization, isinyithi sigalelwa ngokuthe nkqo nge-injection system ebekwe kwisiseko esisezantsi se-crucible (nozzle).

Imijelo emininzi yamanzi oxinzelelo oluphezulu ijolise kwaye igxininise kwintsimbi yentsimbi ukwenzela ukuba kuqinisekiswe ukuqina kwe-alloy esheshayo ngendlela yomgubo ocolekileyo.

Iinguqu zenkqubo yexesha langempela ezifana nobushushu, uxinzelelo lwegesi, amandla okungeniswa, umxholo we-oksijini ppm kwigumbi kunye nezinye ezininzi, ziboniswa kwifomathi yamanani kunye negraphical kwinkqubo yokubeka iliso ukuze kuqondwe ngokucacileyo umjikelo wokusebenza.

Inkqubo inokusebenza ngesandla okanye kwimodi ezenzekelayo ngokupheleleyo, ngenxa yokulungelelaniswa kwayo yonke isethi yeeparameters zenkqubo ngokusebenzisa i-interface-friendly touch-screen interface.

Inkqubo yokwenza iMetal Powder ngeAtomization yamanzi Isixhobo sokuPulverizing

Inkqubo yokwenza umgubo wesinyithi ngamanzi atomization pulverizing izixhobo inembali ende. Kumaxesha amandulo, abantu babegalela intsimbi etyhidiweyo emanzini ukuze igqabhuke ibe ngamasuntswana esinyithi, awayesetyenziselwa ukwenza intsimbi; kude kube ngoku, kusekho abantu abagalela ilothe enyibilikisiweyo ngokuthe ngqo emanzini ukwenza iipellets zelothe. . Ukusebenzisa indlela ye-atomization yamanzi ukwenza i-coarse alloy powder, umgaqo wenkqubo ufana nolulwelo olukhankanywe ngasentla lwamanzi oluqhekezayo lwesinyithi, kodwa ukusebenza kakuhle kwe-pulverization kuye kwaphuculwa kakhulu.

Isixhobo sokucola i-atomization yamanzi senza umgubo wealloyi orhabaxa. Okokuqala, igolide erhabaxa inyibilikiswa ezikweni. I-liquid yegolide encibilikisiweyo kufuneka igqitywe ngama-degrees angama-50, ize igalelwe kwi-tundish. Qalisa impompo yamanzi yoxinzelelo oluphezulu phambi kokuba ulwelo lwegolide lutofwe, kwaye uvumele isixhobo soxinzelelo oluphezulu lwe-atomization yamanzi siqale i-workpiece. Ulwelo lwegolide kwi-tundish ludlula kumqadi kwaye lungene kwi-atomizer ngombhobho ovuzayo osemazantsi e-tundish. IAtomizer sisixhobo esiphambili sokwenza umgubo orhabaxa wealloy yegolide ngoxinzelelo oluphezulu lwenkungu yamanzi. Umgangatho we-atomizer uhambelana nokusebenza kakuhle komgubo wesinyithi. Ngaphantsi kwesenzo samanzi anoxinzelelo oluphezulu olusuka kwiatomizer, ulwelo lwegolide luhlala luqhekeka lube ngamathontsi acolekileyo, awela kulwelo olupholisayo kwisixhobo, kwaye ulwelo luqina ngokukhawuleza lube ngumgubo wealloyi. Kwinkqubo yendabuko yokwenza i-metal powder nge-high-pressure water atomization, i-powder yensimbi ingaqokelelwa ngokuqhubekayo, kodwa kukho imeko yokuba i-powder encinci yensimbi ilahlekile kunye namanzi e-atomizing. Kwinkqubo yokwenza i-alloy powder nge-high-pressure ye-atomization yamanzi, imveliso ye-atomized igxininiswe kwisixhobo se-atomization, emva kwemvula, i-filtration, (ukuba kuyimfuneko, inokomiswa, ngokuqhelekileyo ithunyelwe ngokuthe ngqo kwinkqubo elandelayo.), ukufumana i-alloy powder ecocekileyo, akukho lahleko ye-alloy powder kuyo yonke inkqubo.

Iseti epheleleyo yezixhobo zokucofa iatomization yamanzi Isixhobo sokwenza umgubo wealloyi siquka ezi nxalenye zilandelayo:

Indawo yokunyibilikisa:isithando somlilo esinyibilikisayo esinesantya esiphakathi okanye isithando somlilo esinesantya esiphezulu sesinyithi sinokukhethwa. Umthamo wesithando somlilo unqunywe ngokuhambelana nomthamo wokucutshungulwa komgubo wensimbi, kunye nesithando somlilo esingama-50 kg okanye i-20 kg yesithando somlilo singakhethwa.

Inxalenye yeAtomization:Izixhobo ezikule nxalenye zizixhobo ezingezizo eziqhelekileyo, ezifanele ziyilwe kwaye zilungiswe ngokwemiqathango yesayithi yomenzi. Kukho ubukhulu becala i-tundishes: xa i-tundish iveliswa ebusika, kufuneka ifakwe ngaphambili; I-atomizer: I-atomizer iya kuvela kuxinzelelo oluphezulu Uxinzelelo lwamanzi oluphezulu lwempompo luchaphazela ulwelo lwegolide olusuka kwi-tundish ngesantya esimiselweyo kunye ne-engile, ukuwaphula abe ngamathontsi esinyithi. Ngaphantsi koxinzelelo lwempompo yamanzi efanayo, isixa somgubo wesinyithi ococekileyo emva kwe-atomization sinxulumene nokusebenza kakuhle kwe-atomizer; i-atomization cylinder: yindawo apho i-alloy powder i-atomized, icolile, ipholile kwaye iqokelelwa. Ukuze kuthintelwe i-ultra-fine alloy powder kwi-alloy powder efunyenweyo ukuba ingalahleki ngamanzi, kufuneka ishiywe ixesha elithile emva kwe-atomization, kwaye emva koko ifakwe kwibhokisi yokuqokelela umgubo.

Inxalenye yasemva kokulungiswa:ibhokisi yokuqokelela umgubo: isetyenziselwa ukuqokelela umgubo we-atomized alloy kunye nokwahlula kunye nokususa amanzi angaphezulu; isithando somlilo: yomisa i-alloy powder emanzi ngamanzi; umatshini wokuhlola: hluza i-alloy powder, i-out-of-specification coarser alloy powders inokuphinda inyibilike kwaye i-atomized njengempahla yokubuyisela.

Indlela yoPhuhliso lwe-Atomization yeSixhobo sokuPulverizing kwixesha elizayo

Kusekho iintsilelo ezininzi ekuqondeni itekhnoloji yoshicilelo lwe-3D kuzo zonke iinkalo zoshishino lwemveliso yaseTshayina. Xa sijonga imeko yophuhliso, ukuza kuthi ga ngoku ushicilelo lwe-3D alukhange lufikelele kwishishini eliqolileyo, ukusuka kwizixhobo ukuya kwiimveliso ukuya kwiinkonzo ezisekwinqanaba "lokudlala eliphambili". Nangona kunjalo, ukusuka kurhulumente ukuya kumashishini eTshayina, amathuba ophuhliso lweteknoloji yoshicilelo ye-3D ayaziwa ngokubanzi, kwaye urhulumente kunye noluntu ngokubanzi banikele ingqalelo kwimpembelelo yexesha elizayo le-3D yoshicilelo lwentsimbi ye-atomization yokucofa iteknoloji kwimveliso ekhoyo yelizwe lam, uqoqosho, kunye neemodeli zokuvelisa.

Ngokutsho kwedatha yophando, okwangoku, imfuno yelizwe lam yeteknoloji yoshicilelo lwe-3D ayigxininisi kwisixhobo, kodwa ibonakaliswe kwiintlobo ezahlukeneyo ze-3D zokushicilela kunye nemfuno yeenkonzo zokulungisa i-arhente. Abathengi bemizi-mveliso awona mandla aphambili ekuthengeni izixhobo zoshicilelo ze-3D kwilizwe lam. Izixhobo abazithengayo zisetyenziswa ikakhulu kuphapho, kwi-aerospace, kwiimveliso ze-elektroniki, ezothutho, ukuyila, ukuyila kwenkcubeko kunye namanye amashishini. Okwangoku, umthamo ofakiweyo wabashicileli be-3D kumashishini aseTshayina malunga ne-500, kwaye izinga lokukhula lonyaka li malunga ne-60%. Nangona kunjalo, ubungakanani bemarike yangoku bumalunga ne-100 yezigidi zeeyuan ngonyaka. Imfuno enokubakho ye-R&D kunye nokuveliswa kwemathiriyeli yoshicilelo ye-3D ifikelele phantse kwibhiliyoni enye yeyuan ngonyaka. Ngokuthandwa kunye nenkqubela phambili yeteknoloji yezixhobo, isikali siya kukhula ngokukhawuleza. Kwangaxeshanye, iinkonzo zokusetyenzwa eziphathisiweyo ezinxulumene noshicilelo lwe-3D zithandwa kakhulu, kwaye uninzi lweearhente zoshicilelo lwe-3D Inkampani yezixhobo iqole kakhulu kwinkqubo ye-laser sintering kunye nesicelo sezixhobo, kwaye inokubonelela ngeenkonzo zokulungisa zangaphandle. Ekubeni ixabiso lesixhobo esinye ngokubanzi lingaphezulu kwe-5 yezigidi zeeyuan, ukwamkelwa kweemarike akuphezulu, kodwa inkonzo yokucubungula i-arhente ithandwa kakhulu.

Uninzi lwezixhobo ezisetyenziswa kwilizwe lam 3D yoshicilelo metal atomization pulverizing izixhobo zibonelelwa ngokuthe ngqo ngabavelisi beprototyping ekhawulezayo, kwaye unikezelo lomntu wesithathu wezinto eziqhelekileyo alukaphunyezwa, okukhokelela kwiindleko eziphezulu kakhulu zezinto. Kwangaxeshanye, akukho phando malunga nokulungiswa komgubo onikezelwe kushicilelo lwe-3D eTshayina, kwaye kukho iimfuno ezingqongqo kubungakanani besuntswana losasazo kunye nomxholo weoksijini. Ezinye iiyunithi zisebenzisa umgubo wokutshiza wesiqhelo endaweni yoko, onezinto ezininzi ezingasebenziyo.

Uphuhliso kunye nokuveliswa kwezinto ezisebenza ngeendlela ezininzi ngundoqo kwinkqubela phambili yezobuchwepheshe. Ukusombulula iingxaki zentsebenzo kunye neendleko zezixhobo kuya kukhuthaza ngcono uphuhliso lwetekhnoloji yeprototyping ekhawulezileyo eTshayina. Okwangoku, uninzi lwezixhobo ezisetyenziswa kwilizwe lam loshicilelo lwe-3D olukhawulezayo lwetekhnoloji yeprototyping kufuneka luthengwe kumazwe angaphandle, okanye abenzi bezixhobo batyale amandla amaninzi kunye neemali zokuziphuhlisa, ezixabisa kakhulu, okukhokelela ekunyukeni kweendleko zemveliso, ngelixa. izinto zasekhaya ezisetyenziswe kulo matshini zinamandla aphantsi kunye nokuchaneka. . Ukwenziwa kwendawo yezinto zoshicilelo ze-3D kunyanzelekile.

I-Titanium kunye ne-titanium alloy powders okanye i-nickel-based kunye ne-cobalt-based based superalloy powders kunye nomxholo ophantsi we-oksijeni, ubungakanani beqhekeza elincinci kunye ne-sphericity ephezulu iyafuneka. Ubungakanani bepowder particle ubukhulu becala -500 mesh, umxholo we-oksijeni kufuneka ube ngaphantsi kwe-0.1%, kwaye ubungakanani be-particle bufanayo Okwangoku, i-powder-alloy powder ephezulu kunye nezixhobo zokuvelisa zisaxhomekeke kakhulu ekungenisweni kwamanye amazwe. Kumazwe angaphandle, izinto ezikrwada nezixhobo zidla ngokudityaniswa zize zithengiswe ukuze kufunyanwe ingeniso eninzi. Ukuthatha i-nickel-based powder njengomzekelo, ixabiso lezinto eziluhlaza malunga ne-200 yuan / kg, ixabiso leemveliso zasekhaya ngokuqhelekileyo li-300-400 yuan / kg, kwaye ixabiso le-powder ephuma kwamanye amazwe lihlala lingaphezulu kwe-800 yuan / kg.

Umzekelo, impembelelo kunye nokuguquguquka kokwakheka komgubo, ukufakwa kunye neepropathi ezibonakalayo kwiitekhnoloji ezinxulumene ne-3D yoshicilelo lwentsimbi ye-atomization izixhobo zokugaya umgubo. Ke ngoko, ngokweemfuno zokusetyenziswa komxholo weoksijini ephantsi kunye nomgubo ocolekileyo wobungakanani besuntswana, kuseyimfuneko ukwenza umsebenzi wophando onje ngokwakheka koyilo lwe-titanium kunye ne-titanium alloy powder, itekhnoloji yokugaya igesi ye-atomization yomgubo ocolekileyo, kunye impembelelo yeempawu zomgubo ekusebenzeni kwemveliso. Ngenxa yokunciphisa iteknoloji yokugaya e-China, kunzima ukulungiselela i-powder-grained powder ngoku, isivuno somgubo siphantsi, kwaye umxholo we-oksijeni kunye nezinye izinto ezingcolileyo ziphezulu. Ngethuba lenkqubo yokusetyenziswa, i-powder melting state ihambelana nokungalingani, okubangelwa umxholo ophezulu we-oxide inclusions kunye nemveliso ye-denser kwimveliso. Ezona ngxaki ziphambili zomgubo wengxubevange yasekhaya zikumgangatho wemveliso kunye nozinzo lwebhetshi, kubandakanywa: ① uzinzo lwamacandelo omgubo (inani lokufakwa, ukufana kwamacandelo); ② umgubo ngokwasemzimbeni Ukuzinza kokusebenza (ubungakanani besuntswana losasazo, i-powder morphology, fluidity, ratio exegeyo, njl.); ③ ingxaki yesivuno (isivuno esiphantsi somgubo kwicandelo elimxinwa lobungakanani besuntswana), njl.

Umboniso weMveliso

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur