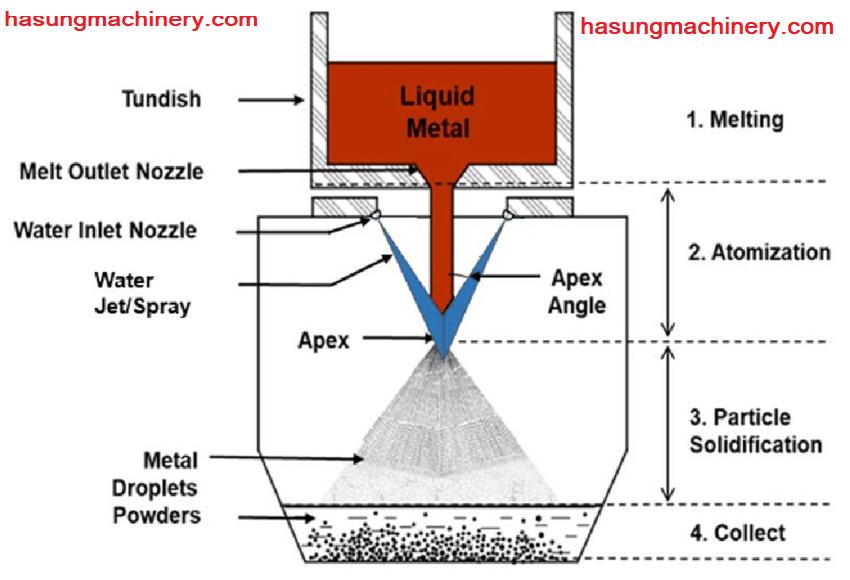

Esi sixhobo sisetyenziselwa ukwenza umgubo wesinyithi okanye igranule kwi-atomization. igumbi ngendlela yoxinzelelo oluphezulu lwe-atomization yamanzi emva kwesinyithi okanye i-alloy yensimbi. inyibilike phantsi kwendawo yokukhusela igesi okanye indawo yomoya eqhelekileyo. Iindleko zokusebenza zomatshini kunye neendleko zokuvelisa umgubo ziphantsi. Isixhobo se-Metal Powder Atomization yaManzi luhlobo lobuchule bokulungela umgubo apho isinyithi okanye incindi edityanisiweyo iqhekezwe ibe ngamaso amancinane ngolwelo olukhawulezayo (i-atomization medium) ngokuzulazula okanye ngeendlela ezitshintshanayo, ezilandelelwa ngokwakhiwa zibe ngumgubo owomeleleyo. Nayiphi na into enokubumba ulwelo inokuba yi-atom kwaye ibe ngumgubo. Uxinzelelo oluphezuluatomization yamanziubuchule bunokwenza ngemali nangendlela eyiyo iMIM yesinyithi i-amalgam powder, umgubo wentsimbi onyangwa ngokukodwa, umgubo wentsimbi okhawulezayo, umgubo wesinyithi oxabisekileyo, umgubo oxutywe ngobhedu, kunye nePowder edityanisiweyo ephezulu, njalo njalo. Ezona zisetyenziswa ngokubanzi ziZixhobo zegesi zeatomization kunye neZixhobo ze-atomization yamanzi. Ngexesha elichithwe inkqubo yokuhambisa umgubo weatomization, nyibilikisa izinto zesinyithi ezingasulungekanga zibe lulwelo lwe-amalgam olufanelekileyo (ubukhulu becala lufudunyezwe kakhulu kwi-100-150 ℃) sisifudumezi sombane okanye isifudumezi sokwamkela, kwaye emva koko sifakwe kwi-tundish phezu kwe-atomizing spout. Ulwelo oludityanisiweyo luphuma luphuma kwimbobo yokuchitheka kwindawo esezantsi ye-tundish, kwaye xa ludlula kwi-spout, luthi lwe-atom lube ngamaso acolekileyo xa lufumana umoya okhawulezayo okanye umsinga wamanzi. Amathontsi e-athomu aqiniswa ngokukhawuleza abe ngumgubo odibeneyo kwigumbi elivaliweyo le-atomizing. Ngokubanzi, igesi engasebenziyo i-atomized powder particles ingqukuva, inomxholo ophantsi we-oksijini (ngaphantsi kwe-100 × 10), kwaye inokwenziwa ngokuthe ngqo kwizinto ezixinzelelekileyo nge-thermoforming innovation, (umzekelo, i-isostatic squeezing eshushu). Amanzi e-atomized powder particles ubukhulu becala imilo engalindelekanga kunye nomxholo ophezulu we-oksijeni (ngaphezu kwe-600 × 10) kwaye kufuneka ihlanjululwe. Inobunzima obukhulu kwaye inokucinezelwa ngokubanda kwiindawo zoomatshini.

Umgaqo wokusebenza

Indlela ebandakanyekayo ekuhambiseni umgubo wesinyithi nge-atomization yamanzi yokupompa izixhobo zokucoca inembali ende. Kumaxesha amandulo, abantu babegalela i-iron elulwelo emanzini baze bayigqabhuze ibe ngamasuntswana entsimbi, awayesetyenziswa njengenxalenye engacocwanga yokwenza intsimbi; ukuza kuthi ga kweli nqanaba, kukho abantu abakhupha ulwelo olulothe ngokuthe ngqo emanzini ukwenza izithonga zelothe. Isicwangciso sokungqinga iatomization yamanzi sisetyenziselwa ukwenza umgubo orhabaxa wekhompawundi. Isikhokelo somjikelo silingana nesi sithethe ngaso ngaphambili sivumela amanzi ukuba aqhumis’ intsimbi engamanzi, ukanti imveliso etshabalalisayo iphuculwe kakhulu. Ukwenza umgubo orhabaxa wokudibanisa nge-atomization yamanzi igiya yokumpompa, igolide erhabaxa kufuneka inyibilikiswe kwisifudumezisi kuqala, kwaye igolide elulwelo kufuneka ifudunyezwe kakhulu malunga ne-50 degrees. Emva koko, ngelo xesha, ifakwe kwi-tundish. Qala i-siphon yamanzi yoxinzelelo oluphezulu ngaphambi kokuba kufakwe ulwelo lwegolide, kwaye uvumele igajethi ye-atomization yamanzi enoxinzelelo oluphezulu iqale i-workpiece. Ulwelo lwegolide olukwi-tundish ludlula kwi-bar kwaye lungene kwi-atomizer ngokusebenzisa i-spout spout kwindawo engezantsi ye-bundle. Iatomizer sesona sixhobo sibalulekileyo sokuzisa umgubo wegolide orhabaxa onenkungu enkulu yamanzi. Ubume be-atomizer ichongiwe ngobuchule obutshabalalisayo bomgubo wesinyithi. Phantsi komsebenzi wamanzi anoxinzelelo oluphezulu olusuka kwiatomizer, ulwelo lwegolide luhlala luqhekezwa lube ngamaso acolekileyo, athi awele kulwelo olupholisayo kwigajethi, kwaye lukhawuleze lwesamente lube ngumgubo we-amalgam. Kwinkqubo yesiko yoxinzelelo oluphezulu lwe-atomization yamanzi yokuzisa umgubo wesinyithi, umgubo wesinyithi unokuqokelelwa ngokuqhubekayo, kodwa ubungakanani obuncinci bomgubo wesinyithi buya kulahleka ngamanzi ane-athomu. I-atomization yamanzi yoxinzelelo oluphezulu, into ye-athomu ifakwe kwigajethi ye-atomization, ikhawuleza, ihluzwe, (ukuba ibalulekile, inokuthi yomiswe kakuhle, ngokuqhelekileyo ihanjiswe ngokuthe ngqo kwi-system elandelayo.) akukho kunqongophala komgubo we-amalgam kuwo wonke umjikelo. ukanti isixa esincinci somgubo wesinyithi siya kulahleka kunye namanzi ane-atom. I-atomization yamanzi yoxinzelelo oluphezulu, into ye-atomized ipakishwe kwigajethi ye-atomization, ikhawuleza, ihluzwe, (ukuba ibalulekile, inokuthi yomiswe kakuhle, ngokuqhelekileyo ihanjiswe ngokuthe ngqo kwi-system elandelayo.) akukho kunqongophala komgubo we-amalgam kuwo wonke umjikelo. ukanti isixa esincinci somgubo wesinyithi siya kulahleka kunye namanzi ane-atom. I-atomization yamanzi yoxinzelelo oluphezulu, into ye-atomized ipakishwe kwigajethi ye-atomization, ikhawuleza, ihluzwe, (ukuba ibalulekile, inokuthi yomiswe kakuhle, ngokuqhelekileyo ihanjiswe ngokuthe ngqo kwi-system elandelayo.) akukho ntsilelo ye-amalgam powder kuwo wonke umjikelo.

Ulungelelwaniso lulonke lwezixhobo zentsimbi yomgubo we-atomization yamanzi zibandakanya iindawo ezihamba kunye: Ukunyibilika inxalenye: Unokukhetha i-medium frequency frequency metal smelting furnace okanye i-high-frequency metal smelting furnace. Umthamo wesithando somlilo uxhomekeke kumthamo wokucubungula we powder yensimbi. Unokukhetha i-furnace ye-50 kg okanye i-20 kg yesithando somlilo. Inxalenye ye-Atomization: Le nxalenye yesixhobo ayisona sixhobo esingaqhelekanga, esimele siyilwe kwaye silungiswe ngokwemiqathango yesayithi yomenzi, ngokukodwa kubandakanywa ne-tundish: xa i-tundish ikhiqizwa ebusika, idinga ukufudumeza kwangaphambili; Iatomizer: Iatomizer ichaphazela amanzi oxinzelelo oluphezulu ukusuka kwimpompo yamanzi yoxinzelelo oluphezulu ngesantya esimiselweyo kunye ne-engile ngokuchasene nolwelo lwegolide olusuka kwi-tundish, ukuwaphula abe ngamathontsi esinyithi. Ngaphantsi koxinzelelo lwempompo efanayo, ubungakanani bepowder yentsimbi ecocekileyo emva kwe-atomization ihambelana nokusebenza kakuhle kwe-atomizer; i-atomization cylinder: yindawo apho i-alloy powder i-atomized, icolile, ipholile kwaye iqokelelwa. Ukuze uthintele umgubo wealloyi ogqwesileyo ukuba ungalahleki ngamanzi, umgubo olungiselelwe umgubo kufuneka uvunyelwe ume kangangexesha elithile emva kokucolwa kwe-atomization, emva koko ubekwe kwibhokisi yokwamkela umgubo. Inxalenye yePost-processing: ibhokisi yokuqokelela umgubo: isetyenziselwa ukuqokelela i-atomized alloy powder, ukwahlukana kunye nokususwa kwamanzi angaphezulu; isithando somlilo: ukomisa i-alloy powder emanzi ngamanzi; umatshini wokuhlola: ukuhlolwa kwe-alloy powder, I-coarser alloy powder engahambelani neenkcukacha ingasetyenziselwa njengento yokunyibilika kwakhona kwaye i-atomized.

Isixhobo se-ultra-high-high metal powder powder water atomization sinezi mpawu zilandelayo

I-1-Ingasetyenziselwa uninzi lwesinyithi kunye nomgubo odibeneyo, kwaye indleko yokudala iphantsi.

I-2-Inokucwangcisa i-powder subspherical okanye i-sporadic powder.

3-Ngenxa yesamente ekhawulezayo kwaye akukho kwahlulwa, uninzi lweepowder ze-amalgam ezizodwa zinokulunga.

I-4-Ubungakanani be-molecule ye-powder bunokufikelela ekufikeleleni okuyimfuneko ngokutshintsha inkqubo yokufaneleka.

Ibonelela ngekhwalithi yentsimbi

Ngolwazi oluthe vetshe Nceda

Sithumele i-imeyile :-info@hasungmachinery.com sales@hasungmachinery.com

Iwebhusayithi: www.hasungcasting.comhttps://hasungmachinery.com/

Ixesha lokuposa: Jun-30-2022