I-WIRE BODING

IPHEPHA LESISEKO SOLWAZI

Yintoni i-Wire Bonding?

Ukudityaniswa kocingo yindlela apho ubude obuncinci bentsimbi yentsimbi ethambileyo buncanyathiselwe kumphezulu wesinyithi ohambelanayo ngaphandle kokusebenzisa i-solder, i-flux, kwaye kwezinye iimeko kunye nokusetyenziswa kobushushu obungaphezulu kwe-150 degrees Celsius. Iintsimbi ezithambileyo ziquka iGolide (Au), iCopper (Cu), iSilivere (Ag), iAluminium (Al) kunye ne-alloys ezifana nePalladium-Silver (PdAg) kunye nabanye.

Ukuqonda ubuChwepheshe boBonding bocingo kunye neeNkqubo zeMicro Electronics kwiSicelo seNdibano.

Ubuchwephesha bokudibanisa iWedge / Iinkqubo: IRibhoni, iBhola yeThermosonic kunye ne-Ultrasonic Wedge Bond

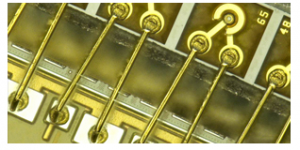

I-wire bonding yindlela yokwenza i-interconnects phakathi kwesekethe edibeneyo (IC) okanye isixhobo esifanayo se-semiconductor kunye nephakheji yayo okanye i-leadframe ngexesha lokuvelisa. Ikwasetyenziswa ngokuqhelekileyo ngoku ukubonelela uxhulumaniso lombane kwi-Lithium-ion battery pack assemblies.I-wire bonding ngokuqhelekileyo ithathwa njengeyona nto ibiza kakhulu kwaye iguquguqukayo yobuchwephesha obukhoyo be-microelectronic interconnect, kwaye isetyenziswe kuninzi lweepakethe ze-semiconductor eziveliswa namhlanje. Zininzi iindlela zokubophelela ngocingo, eziquka:Thermo-Compression Wire Bonding:

I-Thermo-compression wire bonding (ukudibanisa kwindawo enokwenzeka (edla ngokuba yi-Au) kunye phantsi kwamandla abambekayo anobushushu obuphezulu bojongano, ubukhulu becala obungaphezulu kwe-300°C, ukuvelisa i-weld), kwaqalwa kwaphuhliswa ngeminyaka yee-1950 kuthungelwano lwe-microelectronics, nangona kunjalo oku kwakusenzeka. ngokukhawuleza ithathelwe indawo yi-Ultrasonic & Thermosonic bonding kwi-60's njengeyona teknoloji yonxibelelwano oluphambili. I-Thermo-compression bonding isasetyenziswa kwizicelo ze-niche namhlanje, kodwa ithintelwa ngokubanzi ngabavelisi ngenxa yojongano oluphezulu (oluhlala luyingozi) amaqondo obushushu afunekayo ukuze kwenziwe ibhondi eyimpumelelo.Ultrasonic Wedge Wire Bonding:

Ngeminyaka yee-1960s I-Ultrasonic wedge wire bonding yaba yeyona ndlela ibalaseleyo yoqhagamshelwano. Ukusetyenziswa kwe-vibration ephezulu (nge-resonating transducer) kwisixhobo se-bonding kunye ne-camping force yaxeshanye, ivumele i-Aluminiyam kunye neengcingo zeGolide ukuba zifakwe kwiqondo lokushisa. Le vibration ye-Ultrasonic inceda ekususeni ukungcola (i-oxides, ukungcola, njl.) ukusuka kwiindawo ezidibeneyo ekuqaleni komjikelezo wokudibanisa, kunye nokukhuthaza ukukhula kwe-intermetallic ukuqhubela phambili ukuphuhlisa nokuqinisa ibhondi. Iifrikhwensi eziqhelekileyo zokudityaniswa yi-60 – 120 KHz. Ubuchule be-wedge be-ultrasonic bubuchwephesha benkqubo ezimbini eziphambili:Ucingo olukhulu (olunzima) oludityanisiweyo lweingcingo ezidayamitha > 100µm iingcingo ezidayamitha eziLungileyo (ezincinci) zokudityaniswa kweengcingo ze-<75µm zedayamitha ye-<75µmImizekelo yesiqhelo yokudibanisa i-Ultrasonic efumaneka apha ngocingo oluhle kwaye apha ngocingo olukhulu.Ultrasonic i-wedge wire bonding isebenzisa isixhobo esithile sokudibanisa okanye "i-wedge," ngokuqhelekileyo yakhiwe kwi-Tungsten Carbide (ye-Aluminium wire) okanye i-Titanium Carbide (ye-Gold wire) ngokuxhomekeke kwiimfuno zenkqubo kunye needayamitha zocingo; i-ceramic enencam yeedge zezicelo ezahlukileyo zikwakhona.Thermosonic Wire Bonding:

Apho kufuneka ukufudumeza okongeziweyo (ngokuqhelekileyo kwi-Gold wire, kunye nojongano lwe-bonding kuluhlu lwe-100 - 250 ° C), inkqubo ibizwa ngokuba yi-Thermosonic wire bonding. Oku kuneengenelo ezinkulu ngaphezulu kwenkqubo yocinezelo yemveli ye-thermo, njengoko kufuneka amaqondo obushushu ojongano olusezantsi kakhulu (ukudibanisa i-Au kwiqondo lobushushu begumbi kukhankanyiwe kodwa xa kusenziwa akuthembekanga ngaphandle kobushushu obongezelelweyo).Thermosonic Ball Bonding:

Olunye uhlobo lwe-Thermosonic wire bonding yiBall Bonding (bona umjikelo webhondi yebhola apha). Le ndlela yokusebenza isebenzisa isixhobo se-ceramic capillary bonding ngaphezulu koyilo lwe-wedge yendabuko ukudibanisa ezona mpawu zibalaseleyo kuzo zombini i-thermo-compression kunye ne-ultrasonic bonding ngaphandle kwemiqobo. I-Thermosonic vibration iqinisekisa ukuba ubushushu be-interface buhlala buphantsi, ngelixa i-interconnect yokuqala, ibhondi yebhola ye-thermolly-compressed ivumela ukuba i-wire kunye ne-secondary bond ibekwe kulo naliphi na icala, kungekhona emgceni kunye nebhondi yokuqala, eyisithintelo kwi-Ultrasonic wire bonding. . Ukwenziwa ngokuzenzekelayo, ukwenziwa kwevolyum ephezulu, izibophelelo zebhola zikhawuleza kakhulu kune-Ultrasonic / Thermosonic (Wedge) iibhondi, nto leyo eyenza ukuba ibhola ye-Thermosonic idibanise ubuchwephesha obuphezulu bonxibelelwano kwi-microelectronics kwiminyaka engama-50+ yokugqibela.

Ukudityaniswa kweribhoni, kusetyenziswa iiteyiphu zentsimbi ezisicaba, ibiyeyona iphambili kwiRF nakwiMicrowave elektroniki kangangamashumi eminyaka (iribhoni ibonelela ngophuculo olubonakalayo ekulahlekeni komqondiso [umphumo wolusu] ngokuchasene nocingo olungqukuva oluqhelekileyo). Iiribhoni zeGolide ezincinci, eziqhele ukuya kuthi ga kwi-75µm ububanzi kunye ne-25µm ubukhulu, zibotshelelwe ngenkqubo ye-Thermosonic ngesixhobo esikhulu esinobuso obumcaba. imfuno ye-loop ephantsi, uqhagamshelwano oluphezulu loxinaniso lunyukile.

Yintoni igolide yokubopha ucingo?

Ukudityaniswa kocingo lwegolide yinkqubo apho ucingo lwegolide luncanyathiselwa kumanqaku amabini kwindibano ukwenza uqhagamshelo okanye indlela yombane. Ukushisa, i-ultrasonics, kunye ne-force zonke ziqeshwe ukwenza iindawo zokunamathisela kwintambo yegolide.Inkqubo yokudala indawo yokunamathisela iqala ngokuqulunqwa kwebhola yegolide kwinqanaba lesixhobo se-wire bond, i-capillary. Le bhola icinezelwe kwindawo yokudibanisa efudumeleyo ngelixa usebenzisa zombini i-application-specific amount of force and frequency of 60kHz - 152kHz of ultrasonic motion with tool.Emva kokuba ibhondi yokuqala yenziwe, ucingo luya kusetyenziswa ngokulawulwa ngokuqinileyo. indlela yokwenza imilo yelophu efanelekileyo yejometri yendibano. Ibhondi yesibini, edla ngokubizwa ngokuba ngumthungo, iye yenziwa kwelinye icala ngokucinezela phantsi ngocingo kunye nokusebenzisa i-clamp ukukrazula ucingo kwibhondi.

Ukudityaniswa kocingo lwegolide kunika indlela yoqhagamshelo ngaphakathi kweepakethe ezinombane kakhulu, phantse ulungelelwaniso lobukhulu kunezinye ii-solders. Ukongeza, iingcingo zegolide zinonyamezelo oluphezulu lwe-oxidation xa kuthelekiswa nezinye izinto zocingo kwaye zithambile kunezona zininzi, eziyimfuneko kwimigangatho ebuthathaka.

Inkqubo inokwahluka ngokusekelwe kwiimfuno zendibano. Ngezinto ezibuthathaka, ibhola yegolide inokubekwa kwindawo yesibini yokudibanisa ukuze yenze zombini ibhondi eyomeleleyo kunye nebhondi "ethambileyo" ukukhusela umonakalo kumphezulu wecandelo. Ngezithuba eziqinileyo, ibhola enye ingasetyenziselwa njengesiqalo sebhondi ezimbini, ukwenza ibhondi emise "V". Xa intambo yocingo kufuneka ibe yomelele ngakumbi, ibhola inokubekwa phezu kwe-stitch ukwenza ibhondi yokhuseleko, ukwandisa ukuzinza kunye namandla ocingo. Usetyenziso oluninzi olwahlukeneyo kunye neeyantlukwano ekudibaneni kocingo phantse azinamda kwaye zinokufezekiswa ngokusetyenziswa kwesoftware ezenzekelayo kwiisistim zebhondi yocingo kaPalomar.

Uphuhliso lokudityaniswa kocingo:

Ukudityaniswa ngocingo kwafunyaniswa eJamani ngeminyaka yoo-1950 ngoqwalaselo lovavanyo lwethamsanqa kwaye emva koko iye yaphuhliswa yaba yinkqubo elawulwa kakhulu. Namhlanje isetyenziswa kakhulu ukudibanisa ngombane i-semiconductor chips ukupakisha izikhokelo, iintloko zedisk drive kwii-pre-amplifiers, kunye nezinye izicelo ezininzi ezivumela ukuba izinto zemihla ngemihla zibe zincinci, "zihlakaniphe", kwaye zisebenze ngakumbi.

Izicelo zeeNcingo zoBonding

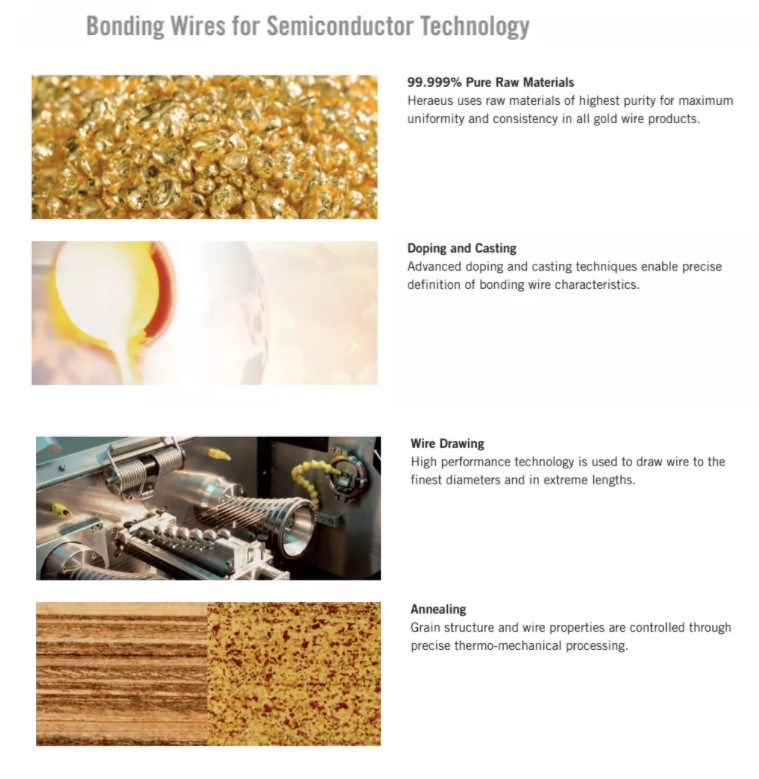

Ukunyuka kweminiaturization kwi-elektroniki kube nesiphumo

kwiintambo zokubopha zibe yinxalenye ebalulekileyo ye

iindibano ze-elektroniki.

Ngenxa yale njongo iingcingo zokudibanisa ezicolekileyo kunye ne-ultrafine ze

igolide, i-aluminiyam, ubhedu kunye ne-palladium zisetyenziswa. Ephezulu

iimfuno zenziwe kumgangatho wazo, ngakumbi ngokumalunga

ukufana kweempawu zocingo.

Ngokuxhomekeke kukwakheka kweekhemikhali kunye nezinto ezithile

iipropati, iingcingo zokudibanisa zilungelelaniswa kwi-bonding

ubuchule obukhethiweyo kunye noomatshini bokudibanisa ngokuzenzekelayo njengoko

kunye nemiceli mngeni eyahlukeneyo kwiitekhnoloji zokuhlanganisa.

I-Heraeus Electronics inikeza uluhlu olubanzi lwemveliso

kwizicelo ezahlukeneyo ze

Ushishino lweemoto

Unxibelelwano

Abavelisi beSemiconductor

Ishishini lempahla yabathengi

Amaqela emveliso yeHeraeus Bonding Wire ngala:

Iingcingo zokudityaniswa kwezicelo kwiplastiki ezaliswe

izixhobo ze-elektroniki

I-aluminiyam kunye ne-aluminiyam i-alloy bonding iingcingo ze

izicelo ezifuna ubushushu bokuqhuba obuphantsi

Iingcingo zokudibanisa ubhedu njengezobugcisa kunye

enye indlela yoqoqosho kwiingcingo zegolide

Iirebhoni zentsimbi ezixabisekileyo nezingeyoxabiso ze

unxibelelwano lombane kunye neendawo ezinkulu zoqhagamshelwano.

Iintambo zoBonding Line Production

Ixesha lokuposa: Jul-22-2022