Umboniso weVidiyo

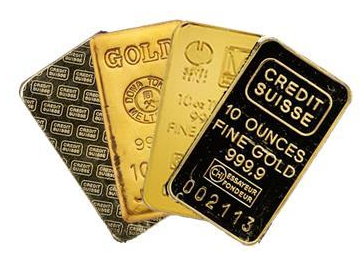

UHasung njengomboneleli wesisombululo sentsimbi exabisekileyo exabisekileyo, uye wakha iingqekembe ezininzi zokwenza imigca kwihlabathi jikelele. Ubunzima bengqekembe busuka kwi-0.6g ukuya kwi-1kg yegolide enemilo engqukuva, yesikwere, kunye ne-octagon. Ezinye iintsimbi zikwafumaneka njengesilivere nobhedu.

Unokwenza ibhanki kunye ne-Hasung ukukubonelela ngesisombululo esinye sokumisaingqekembe minding line. Ipakethe yokuvelisa ibandakanya isikhokelo esikwisiza, izixhobo zokwenziwa kweengqekembe zemali, kunye neenjineli zokukunceda wenze isikali kwinkqubo. Iinjineli zethu ziye zabandakanyeka kuphando lwenkqubo yokwenza iingqekembe zegolide kwaye zisebenze njengabacebisi bobuchwephesha kwiminti enkulu eyaziwayo.

I-Hasung igxile ekusombululeni iingxaki zokwenziwa kwengqekembe ngelixa inika imiyalelo yenyathelo ngenyathelo kwiintsimbi ezixabisekileyo. Kangangeminyaka engama-20+ besihamba phambili koomatshini bokwenza iinkozo zegolide nezesilivere, sinenkonzo yobunjineli echubekileyo nenobuchule, uqeqesho esizeni, kunye nenkxaso yobugcisa.

Nceda ucofeumatshini wokuphosa oqhubekayo kunye noomatshini abaqengqelekayoukujonga iinkcukacha.

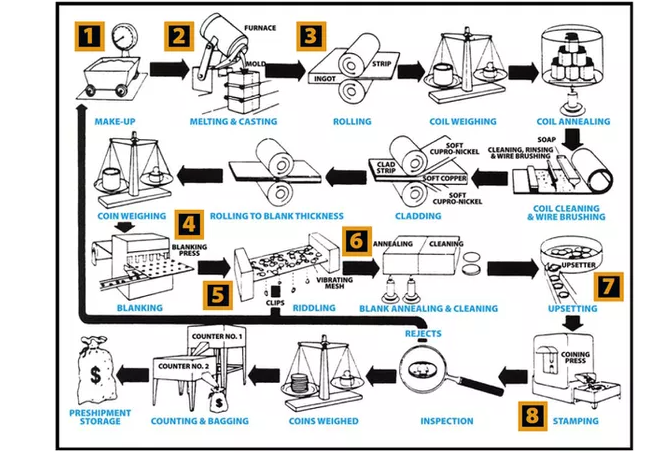

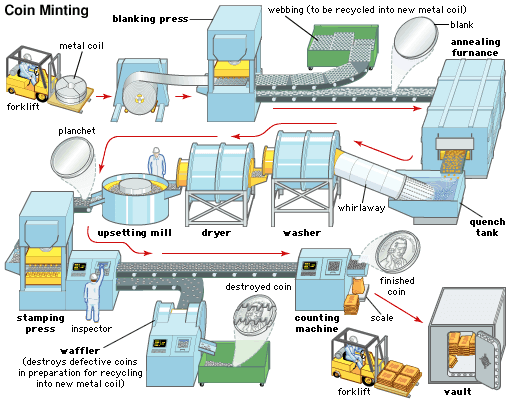

Zenziwa Njani Iingqekembe zemali?

Iindlela ezisetyenziselwa ukwenza iingqekembe zemali ziye zaguquka ngokuhamba kweminyaka. Iingqekembe zenziwa okokuqala kubukumkani bamandulo baseLidiya ngaphezu kweminyaka engamawaka amabini eyadlulayo. Ukwenziwa kweengqekembe zakudala kwakulula kakhulu. Okokuqala, igaqa elincinane legolide, isilivere okanye ubhedu lalifakwa kwingqekembe yemali efakwe kwindawo eqinileyo njengelitye. Umsebenzi wayethabatha ingqekembe yesibini, ayibeke ngaphezulu, aze ayibethe ngehamile enkulu.

Iiminti zamaxesha aphakathi zasebenzisa iidiski ezingqukuva ezenziwe kwangaphambili zentsimbi kunye ne-screw press ukwenza ezi ngqekembe. Nangona le yayiyinkqubo yezandla, yayilula kwaye ivelisa umgangatho ongaguqukiyo kunenkqubo yamandulo yokumbiwa.

Iingqekembe zale mihla zenziwa ngoomatshini bokwenza imali nge-hydraulic abondla ngokuzenzekelayo izikhewu kumatshini. Xa umatshini usebenza ngokupheleleyo, umatshini wokushicilela unokwenza imali engaphezu kwama-600 ngomzuzu. Esi santya siyimfuneko kumsebenzi ofana ne-United States Mint, ekufuneka ivelise iibhiliyoni zeengqekembe minyaka le.

Nangona le nkqubo intsonkothile ngenxa yomatshini osetyenziselwa ukuvelisa amawaka ezigidi zemali, kukho amanyathelo ambalwa aqhelekileyo asetyenziswa yiminti yehlabathi lonke. I-Mint yase-United States yeyona minti inkulu kwihlabathi, kwaye siza kugxila kwinkqubo yayo yemveliso.

1. Ukumbiwa kweMathiriyeli ekrwada

Inkqubo yokugaya iqala ngokumbiwa kwezinto ezikrwada. Imigodi evela kulo lonke elase-United States kwaye kwihlabathi jikelele ibonelela ngegolide, isilivere, ubhedu, okanye ezinye iintsimbi ezifunekayo. Intsimbi ekrwada efunyenwe kule migodi iqulethe ukungcola okungamkelekanga kwi-coinage.

Ukongeza kwintsimbi ekrwada yokumbiwa ukufumana isinyithi esifunekayo, iMint yase-United States ikwasebenzisa intsimbi ehlaziyiweyo ebuyiselwe kwimithombo eyahlukeneyo. Le mithombo ibandakanya iingqekembe ezingasena "machinable" kwaye zisuswe ekujikelezweni. Endaweni yoko, zibuyiselwa kwiminti, apho ziphinda zisetyenziswe kwiingqekembe ezintsha.

2. Ukusulungekiswa, ukunyibilika, kunye nokuSasa

Intsimbi ekrwada iyacocwa ukuze isuse phantse bonke ukungcola. Ezinye iingqekembe zifuna i-alloy yeentlobo ezimbini okanye ngaphezulu ezahlukeneyo zesinyithi. Intsimbi ecocekileyo iyancibilika, kwaye iindidi ezahlukeneyo njengoko zifunwa yinkcazo zongezwa. Ngokomzekelo, i-United States Mint yenza i-five-cent ngqekembe kwi-75 yepesenti yobhedu kunye ne-25 yepesenti ye-nickel alloy.

Emva kokuba ucoceko olufanelekileyo okanye i-alloy ifezekisiwe, isinyithi sifakwe kwi-ingot. Le mivalo yentsimbi emikhulu equlethe isixa esifanelekileyo sesinyithi njengoko kufunwa yi-mint. Isinyithi sihlolwe kuyo yonke inkqubo ukuqinisekisa ukuba kufunyenwe ubunyulu obufanelekileyo.

3. Ukuqengqeleka

Inkqubo yokugoqa i-ingot kubukhulu obufanelekileyo ingaba yinde kwaye inzima. I-ingot ifakwe phakathi kweerola ezimbini zentsimbi eziqinileyo eziqhubekayo zisondela kwaye zisondele kunye. Le nkqubo iya kuqhubeka de i-ingot igqitywe ibe yintsimbi yentsimbi ebunzima obufanelekileyo kwingqekembe eyenziwayo. Ukongezelela, inkqubo yokuqengqeleka ithambisa isinyithi kwaye itshintshe isakhiwo semolekyuli esivumela ukuba sibethwe lula kwaye sivelise iingqekembe ezikumgangatho ophezulu.

Xa iyimathiriyeli yealloyi, iyafuneka ukuba yenziwe i-annealing phambi kokuyivala.

4. Ukungabi nanto

I-United States Mint isebenzisa imiqulu yentsimbi emalunga nee-intshi ezili-13 ububanzi kwaye inobunzima obungamawaka eeponti. I-roll yentsimbi ayibonakali kwaye inqunyulwe ukuze isuse i-curvature kwinkqubo yokuvelisa. Emva koko idluliswa kumatshini okhupha iidiski zentsimbi ngoku zibubukhulu obufanelekileyo kunye nobubanzi bengqekembe eyenziwayo.

5. Ukuhlekisa

Ukuza kuthi ga ngoku, inkqubo yokuvelisa esetyenziselwa ukwenza iintsimbi zentsimbi ingcolile kwaye iqhutywe kwindawo enzima. Kuyenzeka ukuba amaqhekeza amancinci enkunkuma adityaniswe kunye nezikhewu zengqekembe. Umatshini wokuxova wahlula izikhewu ezinobungakanani ngokufanelekileyo kuyo nayiphi na into yangaphandle exutywe nezikhewu zengqekembe.

6. Ukucoca kunye nokuCoca

I-minti ke igqithisa ingqekembe yemali kwi-oveni yokuthambisa ukuze ithambe isinyithi ukulungiselela ukubetheka. Izithuba zifakwa kwibhafu yeekhemikhali ukususa nayiphi na ioli kunye nokungcola okunokuba phezu kwengqekembe. Nayiphi na imathiriyeli yangaphandle inokufakwa kwingqekembe ngexesha lenkqubo yokubetha, kwaye kuya kufuneka ichithwe.

7. Iyacaphukisa

Ukukhusela uyilo oluya kuchukumiseka kwingqekembe yentsimbi engenanto, ingqekembe nganye engenanto idlula kumatshini oneseti yeerola ezifumana kancinci kancinci kwaye zigqithise udini lwentsimbi olunyusiweyo kumacala omabini emali yemali. Le nkqubo ikwanceda ekuqinisekiseni ukuba ingqekembe yemali engenanto yi-diameter efanelekileyo ngoko iya kubetha ngokufanelekileyo kumatshini wokushicilela. Emva kwale nkqubo, ingqekembe engenanto ngoku ibizwa ngokuba yiplanchet.

8. Ukunyathela okanye Ukubetha

Ngoku ekubeni iiplanga zilungiswe kakuhle, zathanjiswa zaza zacocwa, ngoku sele zilungele ukubethelwa. Iingqekembe zemali zeshishini zifakwa ngokuzenzekelayo kumatshini wokushicilela ngexabiso elinokufikelela kumakhulu aliqela eengqekembe ngomzuzu. Iingqekembe zobungqina ezenzelwe abaqokeleli zondliwa ngesandla kwi-coining press kwaye zifumana ubuncinane ezimbini kwingqekembe nganye.

9. Ukuhanjiswa

Iingqekembe eziphumelele ukuhlolwa ngoku zilungele ukuhanjiswa. Iingqekembe zemali ezibethwe kwishishini zipakishwa kwiibhegi zokugcina isambuku kwaye zithunyelwe kubathengisi kwihlabathi liphela. Iingqekembe zemali zifakwa kwizibambi ezikhethekileyo kunye neebhokisi kwaye zithunyelwe kwiingqekembe zemali zabaqokeleli kwihlabathi liphela.

Iinkcukacha:

Ilitye lokusila

Kukho iintlobo ezimbini zokusila zokwenza ibha / iingqekembe zemali, umatshini wokuqala wokuqengqeleka wamaphepha wenza umphezulu oqhelekileyo, kulo mzekelo, udla ngokufuna ukugudisa okokugqibela ngepolisha ye-tumbler.

| UMZEKELO Nomb. | HS-8HP | HS-10HP |

| Igama lebrand | HASUNG | |

| I-Voltage | I-380V 50 / 60Hz, izigaba ezi-3 | |

| Amandla | 5.5KW | 7.5KW |

| Irola | ububanzi 120 × ububanzi 210mm | ububanzi 150 × ububanzi 220mm |

| ubulukhuni | 60-61 ° | |

| Imilinganiselo | 980×1180×1480mm | 1080x 580x1480mm |

| Ubunzima | malunga. 600kg | malunga. 800kg |

| Ukubanakho | Ubukhulu bobukhulu bokuqengqeleka bunyuke nge-25mm | Ubukhulu bobukhulu bokuqengqeleka bufikelela kwi-35mm |

| Inzuzo | Isakhelo senziwe ngothuli lwe-electrostatic, umzimba ugcwele i-chrome ehombisekileyo, kunye nesigqubuthelo sentsimbi esingenasici sihle kwaye siyasebenza ngaphandle komhlwa. Isantya esinye / isantya esiphindwe kabini | |

| Emva kweNkonzo yeWaranti | Inkxaso yobugcisa bevidiyo, Inkxaso ye-Intanethi, ii-Spare parts, ukugcinwa kwentsimi kunye nenkonzo yokulungisa | |

Tungsten Steel Mirror Surface Rolling Mill

Olunye uhlobo yi-tungsten steel material roller mirror surface sheet rolling mill. Ngolu hlobo lomatshini wokuqengqeleka, uya kufumana iphepha lomphezulu wesipili.

| Umzekelo No. | HS-M5HP | HS-M8HP | ||

| Igama lebrand | HASUNG | |||

| I-Voltage | 380V; 50/60hz Izigaba ezi-3 | |||

| Amandla | 3.7kw | 5.5kw | ||

| Ubungakanani beRoller yeTungsten | ububanzi 90 × ububanzi 60mm | ububanzi 90 × ububanzi 90mm | ububanzi 100 × ububanzi 100mm | ububanzi 120 × ububanzi 100mm |

| Ukuqina kweRoller | 92-95 ° | |||

| Izinto eziphathekayo | Ibillet yentsimbi ye-tungsten evela kumazwe angaphandle | |||

| Imilinganiselo | 880×580×1400mm | 980×580×1450mm | ||

| Ubunzima | malunga. 450kg | malunga. 500kg | ||

| Iimbonakalo | Ngokuthambisa; drive gear; Ubukhulu beshiti eliqengqelekayo yi-10mm, thinnest 0.1mm; i-extruded sheet metal surface mirror effect; ukutshiza ngomgubo omileyo kwisakhelo, i-decorative hard chrome plating, intsimbi engenasici isigqubuthelo, esihle kwaye esisebenzayo asiyi kuba ngumhlwa. | |||

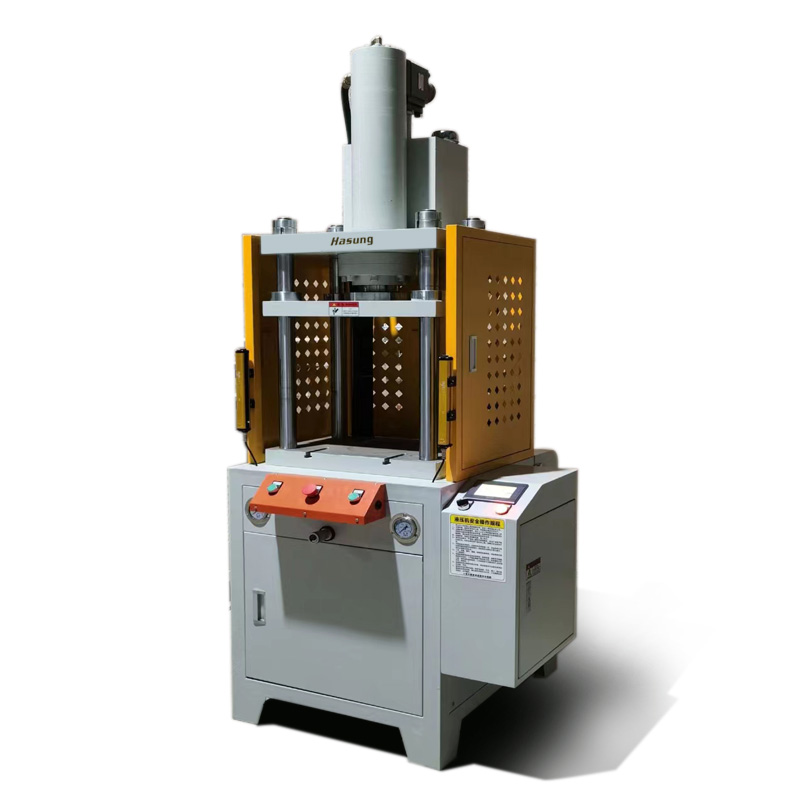

HYDRAULIC COIN BLANKING PRESS

Inkqubo yokuGlankitha

I-20 yeToni ye-Hydraulic Coin Cutting / Press Press

I-40 yeToni ye-Hydraulic Cutting kunye ne-Embossing Press

Lo matshini wokusika wehydraulic usika iphepha elingenanto legolide nesilivere elilungiswa emva kokuqengqeleka. Iphepha elingenanto lisikwa liyilwe elinqwenelekayo libe yingqukuva, uxande, ipendant emile njalo njalo. Ukubonelela ngenkqubo yokusika iifele emva koko izikhewu zibe sele zilungele ukwenziwa kumatshini wokushicilela we-hydraulic stamping.

Izinto eziluncedo kumatshini wokushicilela amandla okusika i-hydraulic.

Ilungele ukusika igolide kunye nesilivere engenanto,

Sika izikhewu kwimida ecacileyo ngeziphumo ezingcono,

Ukusebenza kwasimahla kunye nemowudi emibini esebenza ngonyawo kunye nokutshintsha,

Inkqubo yokumisa ukuqhubeka nokusika,

Inkqubo yohlengahlengiso olufanelekileyo kunye nedrowa yediphozithi elula,

Ukulungiswa kokusika kwimveliso ekhawulezayo.

Ukuxhotyiswa ngesixhobo esingenanto esingenanto, kukulungele ukuqokelela izinto.

Iiparamitha zobuGcisa

| Umzekelo No. | HS-20T | HS-40T | HS-100T |

| Ngobizo | Iitoni ezingama-20 | Iitoni ezingama-40 | Iitoni ezili-100 |

| Istrowuku enkulu | 300mm | 350mm | 400mm |

| Ukuvula ukuphakama | 500mm | 400mm | 600mm |

| Ukuhla ngesantya | 160mm | 180mm | 120mm |

| Ukunyuka kwesantya | 150mm | 160mm | 120mm |

| Indawo yokusebenzela | 600*500mm | 550*450mm | 700*600mm |

| Ukuphakama kwetafile ukusuka emhlabeni | 850mm | 850mm | 850mm |

| I-Voltage | 380V 3 izigaba | 380V 3 izigaba | 380V 3 izigaba |

| Amandla emoto | 3.75kw | 3.75kw | 5.5kw |

| Ubunzima | 1300KG | 860KG | 2200KG |

Iitoni ezili-100I-Hydraulic Coin Embossing Press

150 Ton Hydraulic Coin Embossing Press

200 Ton Hydraulic Coin Embossing Press

I-300 yeToni ye-Hydraulic yeGolide kunye neSilivere yeCoining Press

I-150 yeetoni ze-hydraulic coin embossing press efanelekileyo yokwenza iingqekembe ezifikelela kwi-50 grams ngesilivere. Umshicileli ulungele ukusebenza kwimowudi ye-manual kunye nomjikelo omnye wokusebenza okuzenzekelayo. Iyafumaneka nge-auto coin ejecting mechanisum. Umshicileli unokubonelelwa ngeendlela ezahlukeneyo zetoni njengeetoni ezingama-80, iitoni ezili-100, iitoni ezingama-150, iitoni ezingama-200 ngokwemfuno yakho.

Iitoni ezingama-300 zomthamo womatshini wokushicilela wengqekembe ye-hydraulic yegolide nesilivere egcweleyo kunye nesilawuli se-PLC esicwangcisiweyo semivumbo emininzi kwinqanaba lokugqibela. Umshicileli uxhotyiswe nge-ejector cylinder yokukhupha i-auto ejection yengqekembe ukuze isuswe ngokulula ngaphandle kokubethelwa. Eli nqaku linikeza ukugqitywa okungcono kokugqibela kwengqekembe. Lo matshini wokushicilela we-hydraulic ulungele ukwenza iingqekembe zegolide nezesilivere ukusuka kwi-1.0 gram ukuya kwi-100.0 grams ubunzima kwaye unikwe amandla ngombane we-10.0 HP (7.5KW) kwaye unikezelwa ngokupheleleyo ngombane ofanelekileyo kunye nephaneli yokulawula. Olu yilo lokushicilela ludibanisa ulawulo lohlengahlengiso loxinzelelo kunye nexesha lokulungelelanisa ixesha lokugqibela loxinzelelo ngaphambi kokubuya kwe-stroke. Inokuqhutywa ngolawulo lweqhosha lokutyhala kunye nakwimowudi yomjikelo ozenzekelayo.

Ngaphandle komatshini we-hydraulic coining press kunye ne-precision sheet rolling Mill, udinga i-induction melter okanye umatshini oqhubekayo wokuphosa wegolide kunye nesilivere yokwenza iphepha, umatshini wokusika ibha yegolide kunye nesilivere kunye noomatshini be-vibrator abafunekayo ukuseta isityalo esipheleleyo segolide kunye nesilivere.

Iiparamitha zobuGcisa

| Umzekelo No | HS-100T | HS-200T | HS-300T |

| I-Voltage | 380V, 50/60Hz | 380V, 50/60Hz | 380V, 50/60Hz |

| Amandla | 4KW | 5.5KW | 7.5KW |

| Max. uxinzelelo | 22Mpa | 22Mpa | 24Mpa |

| Ukubetha kwetafile yomsebenzi | 110mm | 150mm | 150mm |

| Max. ukuvula | 360mm | 380mm | 380mm |

| Itheyibhile yokusebenza inyusa isantya sentshukumo | 120mm/s | 110mm/s | 110mm/s |

| Itheyibhile yomsebenzi ngasemva isantya | 110mm/s | 100mm/s | 100mm/s |

| Ubungakanani betafile yomsebenzi | 420*420mm | 500*520mm | 540*580mm |

| Ubunzima | 1100kg | 2400kg | 3300kg |

| Isicelo | ubucwebe kunye nebha yegolide, iingqekembe zemali zokunyathela uphawu | ||

| Uphawu | Eqhelekileyo / i-Servo motor yokhetho, iqhosha lisebenza / iSimens PLC Inkqubo yokulawula ukhetho | ||

Iinkozo eziZimali ezipheleleyo zokwenziwa kweNkqubo yeMveliso

Unokwenza ibhanki kunye ne-Hasung ukukunika isisombululo esisodwa somgca wokwenza imali. Ipakethe yokuvelisa ibandakanya isikhokelo esikwisiza, izixhobo zokwenziwa kweengqekembe zemali, kunye neenjineli zokukunceda wenze isikali kwinkqubo. Iinjineli zethu ziye zabandakanyeka kuphando lwenkqubo yokwenza iingqekembe zegolide kwaye zisebenze njengabacebisi bobuchwephesha kwiminti enkulu eyaziwayo.

I-Hasung igxile ekusombululeni iingxaki zokwenziwa kwengqekembe ngelixa inika imiyalelo yenyathelo ngenyathelo kwiintsimbi ezixabisekileyo. Kangangeminyaka engama-20+ besihamba phambili koomatshini bokwenza iinkozo zegolide nezesilivere, sinenkonzo yobuchwephesha nobuchule bobunjineli, uqeqesho esizeni, kunye nenkxaso yobugcisa Iinkonzo Zethu.

Ixesha lokuposa: Jul-04-2022