Umatshini wokunyibilikisa wokunyibilikisa weGolide weSiliva yeSiliva 2kg 3kg 4kg 5kg 6kg

Iimbonakalo

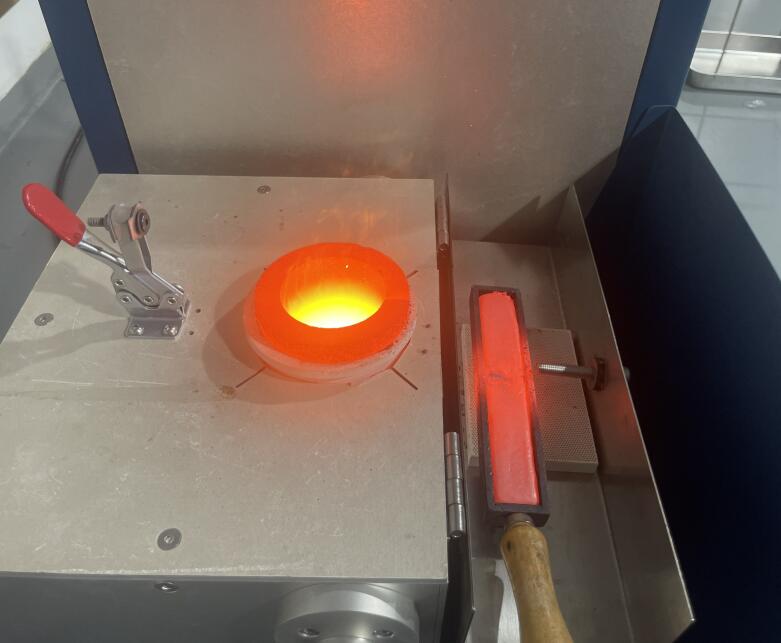

I-Hasung Dual Use yegolide kunye neplatinam yokunyibilikisa iziko inokunyibilikisa ngokufanelekileyo nangokungamandla iplatinam, isilivere, igolide, i-palladium kunye neealloys ezithile.

Ubungakanani obubambeneyo beziko lokunyibilikisa iplatinam kwenza kube lula ukuhambahamba.

I-Hasung multipurpose zegolide kunye neplatinam yokunyibilikisa iziko likwafanelekile ukunyibilika okuncinci kuba inyibilika malunga ne-1g ukuya kwi-2kg yesinyithi ngaxeshanye, ke ngoko, amashishini amancinci afuna ukunyibilika akufuneki akhathazeke ngokufumana iziko lokunyibilika elihlangabezana neemfuno zabo zokunyibilika.

Ukusetyenziswa kwamandla eziko lokunyibilikisa iplatinam yi-15kw, oku kuthetha ukuba amandla ayagcinwa xa kunyibilika ngesithando somlilo seplatinam kwaye akufuneki ube nexhala malunga nenkcitho eyongezelelweyo kumandla ongezelelweyo.

Iziko lokunyibilikisa legolide leHasung kunye neplatinam linokuhlangabezana neemfuno zokunyibilika kwivenkile yamatye anqabileyo, abembi besinyithi bokuzonwabisa, amaziko ophando kunye nokuphinda kusetyenziswe iintsimbi ezindala.

I-Hasung yeenjongo ezininzi zesithando sokunyibilikisa igolide kunye neplatinam ikhuselekile ngokusingqongileyo ukuze isetyenziswe ngendlela yokuba iziko lingavelisi iigesi eziyingozi okanye lenze ingxolo ephazamisayo. Kukwakhuselekile ukuba abasebenzi basebenze njengoko ukuchitheka kwesinyithi esinyibilikisiweyo kungenzeki.

Ixesha lokunyibilika likhawuleza kakhulu, iplatinam yokunyibilika komlilo inyibilika kwi-2100℃ ngaphakathi kwemizuzu emi-2, ngaloo ndlela, yandisa umsebenzi wakho kunye nokusebenza kakuhle kwemveliso.

Zonke isinyithi ezinyibilikisiweyo kunye nesithando sethu sokunyibilikisa iplatinam ngokuqhelekileyo sinokufana okufanayo ukwenzela ukuba xa isinyithi esinjalo sichithwa, sinokugqitywa komgangatho ophezulu.

Umsebenzi wokuvuselela i-electromagnetic induction okhoyo ngaphakathi kwiziko lokunyibilikisa iplatinam wenza inkqubo yokunyibilika isebenze ngokugqithisela ubushushu ngokulinganayo kwaye zonke iindawo zentsimbi zinyibilika ngokulinganayo. Oku kukwathetha ukuba bonke ubushushu obufunekayo ekunyibilikeni busetyenziswa ngokupheleleyo kwiziko, kungoko, akukho ukwanda kobushushu bemekobume yokunyibilika.

Inkqubo yokupholisa amanzi eyakhelwe ngaphakathi ekhoyo ngaphakathi kwesithando somlilo yenza ukuba iqondo lokushisa elinyibilikayo lilawulwe, ngaloo ndlela lithintela ukushisa.

Itekhnoloji yokufudumeza yokungenisa ekhoyo ngaphakathi kwesithando sokunyibilikisa iplatinam yenza ukufakelwa kombane we-electromagnetic kwenzeke, okuthetha ukuba onke amandla afunekayo ekunyibilikiseni asetyenziswa ngokupheleleyo ngaphakathi kwiziko lokunyibilika.

Iziko lokunyibilikisa iplatinam kulula kakhulu ukusebenza. Iphaneli yolawulo yenza kube lula kuwe ukulawula nokubeka iliso kwinkqubo yokunyibilika.

I-Hasung ye-multi-purpose yegolide kunye neplatinam yokunyibilikisa isithando somlilo ikhuselekile ngokusingqongileyo njengoko kungekho bushushu bubangelwa ngexesha lokusetyenziswa, akukho gesi ekhutshwayo kwaye akukho ngxolo eyenzekayo xa inyibilika ngesithando somlilo seplatinam.

Umthamo wokunyibilika wawo nawuphi na umphezulu wokunyibilika ofikelela kuma-2100℃ udla ngokutya amandla agqithisileyo, kodwa izixhobo zethu zokunyibilikisa igolide ezithengiswayo zifuna kuphela i-15kw ukuze ziqalise ukunyibilika zisenza ukuba singabizi kakhulu.

Konke ukunyibilika kwe-8kg kwenziwa ngokufanelekileyo kwimizuzu emi-3, into engenakoyiswa yezixhobo zokunyibilikisa igolide ezithengiswayo. Isantya sokunyibilika sikunceda ukuba uhlangabezane nazo zonke iimfuno zokunyibilika ngokukhawuleza nangokulula ngakumbi.

Igolide, isilivere, ubhedu, ubhedu, iplatinam kunye nezinye izinto ezixutyiweyo zinokunyibilika ngezixhobo zethu zokunyibilikisa igolide. Oku kukuvumela ukuba wonge imali kwezinye izixhobo zokunyibilika.

Inkqubo yempompo yamanzi ekhoyo kwisixhobo sethu sokunyibilikisa igolide yenza ukuba kugcinwe ubushushu obuqhelekileyo xa ukunyibilika kuqhubeka. Ngaloo ndlela, ugcina imali kwizixhobo zokupholisa.

Izixhobo zethu zokunyibilikisa igolide zifanelekile ukunyibilikisa isinyithi kuphando kunye nokufundisa, iziseko, iintsimbi zokuphinda zisetyenziswe kwiivenkile zobucwebe, njl.

Ngokubhekiselele kwimpembelelo yayo kokusingqongileyo, ingxolo yesixhobo sokunyibilikisa igolide nesilivere ngexesha lenkqubo yokunyibilika isezantsi noko kwaye akukho kukhutshwa kwerhasi, umsi okanye uthuli nazo ziphantsi.

Xa kuthelekiswa nezitofu zokuchasa kunye nezitshisi zepropane, izixhobo zokunyibilikisa igolide ze-Hasung ziqinisekisa ukuba akukho lahleko yesinyithi ngexesha lenkqubo yokunyibilika, okwenza izixhobo zethu zokunyibilikisa zisebenze ngakumbi kunezo zombini izitofu ezixhathisayo kunye nezitshisi zepropane.

Izixhobo zethu zokunyibilikisa igolide nesilivere zinokusebenza ngokuqhubekayo kangangeeyure ezingama-24.

Umsebenzisi wesixhobo sokunyibilikisa igolide unolawulo olupheleleyo lweeparamitha zokunyibilika. Ukuba kukho impazamo, inkqubo yesilumkiso se-omni-directional inceda ukuphakamisa ii-alam xa iindawo ezinokuba yingozi zifikelelwe ngexesha lokunyibilika, ngaloo ndlela iqinisekisa ukhuseleko lomsebenzisi.

Ukugcinwa kwezixhobo zegolide kunye nesilivere zokunyibilika kulula njengoko ii-crucibles zichithwa kwaye zinokucocwa emva kwenkqubo nganye yokunyibilika.

Iiparamitha zobuGcisa

| Umzekelo No. | HS-TF2 | HS-TF3 | HS-TF4 | HS-TF5 | HS-TF6 | HS-TF8 | HS-TF10 |

| Amandla | 8KW/15KW | 15KW | 15KW / 20KW | ||||

| I-Voltage | 380V, 50Hz, 3 izigaba | ||||||

| Ubukhulu beTemp | 1600°C | ||||||

| Ixesha lokunyibilika | 2-3 imiz. | 3-5 imiz. | 3-6 imiz. | 4-8 imiz. | 5-8 imiz. | 5-8 imiz. | 6-8 imiz. |

| Ukuchaneka kweTemp | ±1°C (usebenzisa ulawulo lwe-PID ngokuzikhethela) | ||||||

| Ulawulo lwexesha le-PID | Ukhetho | ||||||

| Umthamo (Gold) | 2KG | 3KG | 4KG | 5KG | 6KG | 8KG | 10KG |

| Isicelo | Igolide, K igolide, isilivere, ubhedu kunye nezinye ialloys | ||||||

| Uhlobo lokupholisa | Isibandisi samanzi (athengiswa ngokwahlukeneyo) okanye Amanzi abalekayo (impompo yamanzi) | ||||||

| Indlela yokufudumeza | EJamani IGBT iteknoloji yokufudumeza induction | ||||||

| Imilinganiselo | 90x48x100cm | ||||||

| Ubunzima obuNina (malunga.) | 90kg | 90kg | 100kg | 110kg | 120kg | 130kg | 160kg |

| Ubunzima bokuthumela ngenqanawe (malunga.) | 160kg | 175kg | 180kg | 190kg | 200kg | 220kg | 220kg |

Umboniso weMveliso

-18.png)

Isihloko: Izinto eziluncedo zeHasung manual tilt casting induction melting

Ehlabathini lokuphosa isinyithi kunye nemisebenzi yokuphosa, iziko lokunyibilikisa le-tilt-cast-cast induction liye laba sisixhobo esiyimfuneko ngenxa yokusebenza kakuhle, ukhuseleko kunye nokutsha. Olu yilo oluphambili lwesithando somlilo lubonelela ngeenzuzo ezininzi kubaqhubi kunye nabavelisi, okwenza kube lukhetho oludumileyo ngaphakathi kwishishini. Kule bhlog, siza kuphonononga iingenelo ezininzi zesithando somlilo sokunyibilikisa se-tilt-cast kunye nendlela iimpawu zayo ezintsha, ezifana netreyi ejikelezayo yokubumba igraphite kunye nokwenziwa komgangatho ophezulu, igalelo ekusebenzeni kwayo okuphezulu.

Iziko lokunyibilikisa lokunyibilikisa le-Manual tilt induction libonelela ngoluhlu lweenzuzo ezibenza babe yi-asethi exabisekileyo kwimisebenzi yokuphosa isinyithi. Enye yeenzuzo eziphambili zesi sithando somlilo ngumsebenzi we-tilt manual, ovumela ulawulo oluchanekileyo lwenkqubo yokugalela. Oku akuqinisekisi ukuguquguquka nokugalela nje kuphela, kukwanciphisa umngcipheko wokuchaphaza okanye ukuchitheka, ukubonelela ngemeko-bume ekhuselekileyo yokusebenza kubasebenzi. Ukukwazi ukutshekisa isithando somlilo kunika abaqhubi ukuguquguquka okukhulu kunye nokulawula, okubavumela ukuba bagalele isinyithi esityhidiweyo ngokulula kunye nokuchaneka.

Ukongeza, ukusungulwa kwe-tray ye-graphite mold ejikelezayo yenza i-Hasung manual tilting igalela isithando sokunyibilikisa i-induction eyahlukileyo kwizixhobo zemveli zokunyibilika. Eli nqaku litsha lenza ukuba i-furnace ikwazi ukufaka iimolds ezininzi, ngaloo ndlela ikhulisa ukusebenza kakuhle kunye nemveliso yenkqubo yokuphosa. Iipaliti ezijikelezayo zivumela utshintsho olungenamthungo lokungunda, ukunciphisa ixesha lokuphumla kunye nokwenza lula imveliso. Ukongeza, ubugcisa beziko obukumgangatho ophezulu buqinisekisa ukuqina nokuthembeka, nto leyo eyenza ibe lutyalo-mali lwexesha elide lweziseko kunye nezixhobo zokugalela isinyithi.

Iziko lokunyibilikisa lokunyibilikisa le-Manual tilt induction libonelela ngoluhlu lweenzuzo ezibenza babe yi-asethi exabisekileyo kwimisebenzi yokuphosa isinyithi. Enye yeenzuzo eziphambili zesi sithando somlilo ngumsebenzi we-tilt manual, ovumela ulawulo oluchanekileyo lwenkqubo yokugalela. Oku akuqinisekisi ukuguquguquka nokugalela nje kuphela, kukwanciphisa umngcipheko wokuchaphaza okanye ukuchitheka, ukubonelela ngemeko-bume ekhuselekileyo yokusebenza kubasebenzi. Ukukwazi ukutshekisa isithando somlilo kunika abaqhubi ukuguquguquka okukhulu kunye nokulawula, okubavumela ukuba bagalele isinyithi esityhidiweyo ngokulula kunye nokuchaneka.

Ukongeza, i-innovation ye-graphite mold ejikelezayo yetreyi yenza ukuba i-manual tilting igalele isithando sokunyibilikisa i-induction yahluke kwisixhobo sokunyibilika kwendabuko. Eli nqaku litsha lenza ukuba i-furnace ikwazi ukufaka iimolds ezininzi, ngaloo ndlela ikhulisa ukusebenza kakuhle kunye nemveliso yenkqubo yokuphosa. Iipaliti ezijikelezayo zivumela utshintsho olungenamthungo lokubumba, ukunciphisa ixesha lokunciphisa kunye nokwenza lula imveliso. Ukongeza, ubugcisa beziko obukumgangatho ophezulu buqinisekisa ukuqina nokuthembeka, nto leyo eyenza ibe lutyalo-mali lwexesha elide lweziseko kunye nezixhobo zokugalela isinyithi.

Ukongeza kukhuseleko kunye nokuveliswa kwezinto ezintsha, ii-furnaces zokunyibilikisa ze-tilt-and-cast induction zibonelela ngeenzuzo ezibalulekileyo malunga nokusebenza kwamandla kunye nokusebenza kakuhle kweendleko. Itekhnoloji yokufudumala kwe-induction esetyenziswe kula ma-furnaces iyanyibilika isinyithi ngokukhawuleza kwaye ngokuchanekileyo, ukunciphisa ukusetyenziswa kwamandla kunye neendleko zokusebenza. Oku kwenza isithando somlilo singabi nje ngokusingqongileyo, kodwa sinoqoqosho olusebenzayo kwiziseko kunye nezixhobo zokuphosa isinyithi. Ukukwazi ukuphumeza ukusebenza kakuhle kokunyibilika ngelixa kuncitshiswa ukusetyenziswa kwamandla yeyona nto iphambili kwisixhobo sokunyibilikisa i-tilt-cast cast induction.

Ukongeza, iziko lokunyibilikisa lokunyibilikisa ngesandla le-tilt yenzelwe ukuhlangabezana neemfuno ezahlukeneyo zokusebenza kwesinyithi, ebonelela ngezinto ezahlukeneyo kunye nokuguquguquka kwezicelo ezahlukeneyo. Kungakhathaliseki ukuba imveliso encinci okanye imisebenzi yokuphosa enkulu, isithando somlilo sinokulungelelaniswa kumandla ahlukeneyo okunyibilika kunye neentlobo zetsimbi, okwenza isisombululo esisebenzayo nesisebenzayo kubavelisi. Ukuguquguquka kwesithando somlilo kuvumela ukuhlanganiswa okungenamthungo kwiinkqubo ezikhoyo zokuvelisa, ukwandisa ukusebenza kakuhle kunye nemveliso.

Isishwankathelo, ii-furnaces zokunyibilikisa ze-tilt-cast induction zibonelela ngeenzuzo ezininzi ezibenza zibe sisixhobo esibalulekileyo sokuphosa isinyithi kunye nokusebenza kwesiseko. Iimpawu zayo zokhuseleko, ukuyila okutsha, ubuchwephesha obukumgangatho ophezulu, ukusebenza kakuhle kwamandla kunye nokuguquguquka kwenza kube lutyalo-mali oluxabisekileyo kubavelisi abajonge ukukhulisa iinkqubo zabo zokuphosa. Ngolawulo lwayo oluchanekileyo lwenkqubo yokugalela, i-tray ejikelezayo entsha ye-graphite molds kunye nokusebenza okunexabiso eliphantsi, esi sithando somlilo sitshintsha umdlalo kwishishini lokuphosa isinyithi. Njengoko imfuno yomgangatho ophezulu, izixhobo zokunyibilika ezisebenzayo ziqhubeka nokukhula, iziko lokunyibilikisa le-tilt-cast induction liba sisisombululo esithembekileyo nesiphucukileyo kubavelisi abafuna ukwandisa amandla abo okuphosa.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur