I-Tilting Induction Iziko lokunyibilikisa legolide yePlatinam iPalladium Rhodium 1kg 2kg 3kg 4kg 5kg 6kg 8kg

Iimbonakalo

I-Hasung Dual Use yegolide kunye neplatinam yokunyibilikisa iziko inokunyibilikisa ngokufanelekileyo nangokungamandla iplatinam, isilivere, igolide, i-palladium kunye neealloys ezithile.

I-Hasung's tilting induction isithando somlilo esinyibilikisayo ngoyilo lwebhodi yokhuseleko, isiphatho esithambekileyo sokugalela kuyilo olusecaleni ukuqinisekisa ukhuseleko kubaqhubi.

eHasung'si-tilting induction yokunyibilikisa izikoisebenzisa iqonga aluminiyam oluqinileyo kunye neebhodi zenza isixhobo segumbi lokunyibilikisa elikumgangatho ophezulu. Ngetreyi ejikelezayo yokulayisha ukungunda kwegraphite.

Ubungakanani obubambeneyo beziko lokunyibilikisa iplatinam kwenza kube lula ukuhambahamba.

I-Hasung multipurpose zegolide kunye neplatinam yokunyibilikisa iziko likwafanelekile ukunyibilika okuncinci kuba inyibilika malunga ne-1g ukuya kwi-2kg yesinyithi ngaxeshanye, ke ngoko, amashishini amancinci afuna ukunyibilika akufuneki akhathazeke ngokufumana iziko lokunyibilika elihlangabezana neemfuno zabo zokunyibilika.

Ukusetyenziswa kwamandla kwi-platinam yokunyibilika komlilo yi-5kw, oku kuthetha ukuba amandla agcinwa xa kunyibilika kunye neplatinam yokunyibilika komlilo kwaye akufanele ukhathazeke malunga nenkcitho eyongezelelweyo kumandla ongezelelweyo.

Iziko lokunyibilikisa legolide leHasung kunye neplatinam linokuhlangabezana neemfuno zokunyibilika kwivenkile yamatye anqabileyo, abembi besinyithi bokuzonwabisa, amaziko ophando kunye nokuphinda kusetyenziswe iintsimbi ezindala.

I-Hasung yeenjongo ezininzi zesithando sokunyibilikisa igolide kunye neplatinam ikhuselekile ngokusingqongileyo ukuze isetyenziswe ngendlela yokuba iziko lingavelisi iigesi eziyingozi okanye lenze ingxolo ephazamisayo. Kukwakhuselekile ukuba abasebenzi basebenze njengoko ukuchitheka kwesinyithi esinyibilikisiweyo kungenzeki.

Ixesha lokunyibilika likhawuleza kakhulu, iplatinam yokunyibilika komlilo inyibilika kwi-2100℃ ngaphakathi kwemizuzu emi-2, ngaloo ndlela, yandisa umsebenzi wakho kunye nokusebenza kakuhle kwemveliso.

Zonke isinyithi ezinyibilikisiweyo kunye nesithando sethu sokunyibilikisa iplatinam ngokuqhelekileyo sinokufana okufanayo ukwenzela ukuba xa isinyithi esinjalo sichithwa, sinokugqitywa komgangatho ophezulu.

Umsebenzi wokuvuselela i-electromagnetic induction okhoyo ngaphakathi kwiziko lokunyibilikisa iplatinam wenza inkqubo yokunyibilika isebenze ngokugqithisela ubushushu ngokulinganayo kwaye zonke iindawo zentsimbi zinyibilika ngokulinganayo. Oku kukwathetha ukuba bonke ubushushu obufunekayo ekunyibilikeni busetyenziswa ngokupheleleyo kwiziko, kungoko, akukho ukwanda kobushushu bemekobume yokunyibilika.

Inkqubo yokupholisa amanzi eyakhelwe ngaphakathi ekhoyo ngaphakathi kwesithando somlilo yenza ukuba iqondo lokushisa elinyibilikayo lilawulwe, ngaloo ndlela lithintela ukushisa.

Itekhnoloji yokufudumeza yokungenisa ekhoyo ngaphakathi kwesithando sokunyibilikisa iplatinam yenza ukufakelwa kombane we-electromagnetic kwenzeke, okuthetha ukuba onke amandla afunekayo ekunyibilikiseni asetyenziswa ngokupheleleyo ngaphakathi kwiziko lokunyibilika.

Iziko lokunyibilikisa iplatinam kulula kakhulu ukusebenza. Iphaneli yolawulo yenza kube lula kuwe ukulawula nokubeka iliso kwinkqubo yokunyibilika.

I-Hasung ye-multi-purpose yegolide kunye neplatinam yokunyibilikisa isithando somlilo ikhuselekile ngokusingqongileyo njengoko kungekho bushushu bubangelwa ngexesha lokusetyenziswa, akukho gesi ekhutshwayo kwaye akukho ngxolo eyenzekayo xa inyibilika ngesithando somlilo seplatinam.

Umthamo wokunyibilika wawo nawuphi na umphezulu wokunyibilika ofikelela kuma-2100℃ udla ngokutya amandla agqithisileyo, kodwa izixhobo zethu zokunyibilikisa igolide ezithengiswayo zifuna kuphela i-15kw ukuze ziqalise ukunyibilika zisenza ukuba singabizi kakhulu.

Konke ukunyibilika kwe-8kg kwenziwa ngokufanelekileyo kwimizuzu emi-3, into engenakoyiswa yezixhobo zokunyibilikisa igolide ezithengiswayo. Isantya sokunyibilika sikunceda ukuba uhlangabezane nazo zonke iimfuno zokunyibilika ngokukhawuleza nangokulula ngakumbi.

Igolide, isilivere, ubhedu, ubhedu, iplatinam kunye nezinye izinto ezixutyiweyo zinokunyibilika ngezixhobo zethu zokunyibilikisa igolide. Oku kukuvumela ukuba wonge imali kwezinye izixhobo zokunyibilika.

Inkqubo yempompo yamanzi ekhoyo kwisixhobo sethu sokunyibilikisa igolide yenza ukuba kugcinwe ubushushu obuqhelekileyo xa ukunyibilika kuqhubeka. Ngaloo ndlela, ugcina imali kwizixhobo zokupholisa.

Izixhobo zethu zokunyibilikisa igolide zifanelekile ukunyibilikisa isinyithi kuphando kunye nokufundisa, iziseko, iintsimbi zokuphinda zisetyenziswe kwiivenkile zobucwebe, njl.

Ngokubhekiselele kwimpembelelo yayo kokusingqongileyo, ingxolo yesixhobo sokunyibilikisa igolide nesilivere ngexesha lenkqubo yokunyibilika isezantsi noko kwaye akukho kukhutshwa kwerhasi, umsi okanye uthuli nazo ziphantsi.

Xa kuthelekiswa nezitofu zokuchasa kunye nezitshisi zepropane, izixhobo zokunyibilikisa igolide ze-Hasung ziqinisekisa ukuba akukho lahleko yesinyithi ngexesha lenkqubo yokunyibilika, okwenza izixhobo zethu zokunyibilikisa zisebenze ngakumbi kunezo zombini izitofu ezixhathisayo kunye nezitshisi zepropane.

Izixhobo zethu zokunyibilikisa igolide nesilivere zinokusebenza ngokuqhubekayo kangangeeyure ezingama-24.

Umsebenzisi wesixhobo sokunyibilikisa igolide unolawulo olupheleleyo lweeparamitha zokunyibilika. Ukuba kukho impazamo, inkqubo yesilumkiso se-omni-directional inceda ukuphakamisa ii-alam xa iindawo ezinokuba yingozi zifikelelwe ngexesha lokunyibilika, ngaloo ndlela iqinisekisa ukhuseleko lomsebenzisi.

Ukugcinwa kwezixhobo zegolide kunye nesilivere zokunyibilika kulula njengoko ii-crucibles zichithwa kwaye zinokucocwa emva kwenkqubo nganye yokunyibilika.

Iiparamitha zobuGcisa

| Umzekelo No. | HS-TFQ1 | HS-TFQ2 | HS-TFQ3 | HS-TFQ4 | HS-TFQ5 | HS-TFQ6 | HS-TFQ8 | HS-TFQ10 |

| Amandla | 15KW | 15KW | 20KW | 20KW | 30KW | 30KW | 40KW | 50KW |

| I-Voltage | 380V, 50Hz, 3 izigaba | |||||||

| Ubukhulu beTemp | 2100°C | |||||||

| Ixesha lokunyibilika | 2-3mins | 2-5mins | 3-6mins | 3-6mins | 4-8mins | 3-6mins | 4-8mins | 5-8mins |

| Ukuchaneka kweTemp | ±1°C | |||||||

| Ulawulo lwexesha le-PID | Ukhetho | |||||||

| Umthamo (Pt) | 1KG | 2KG | 3KG | 4KG | 5KG | 6KG | 8KG | 10KG |

| Isicelo | Iplatinam, iPalladiu, iRhodium, iGolide, iK igolide, isilivere, ubhedu kunye nezinye iialloys | |||||||

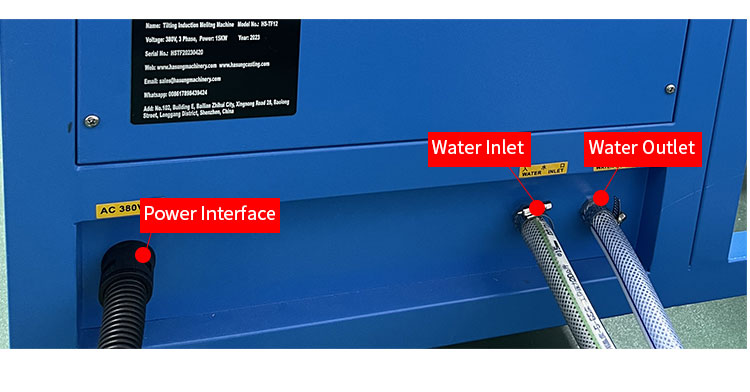

| Uhlobo lokupholisa | Isibandisi samanzi (athengiswa ngokwahlukeneyo) okanye Amanzi abalekayo (impompo yamanzi) | |||||||

| Uhlobo lokufudumeza | EJamani IGBT iteknoloji yokufudumeza induction | |||||||

| Imilinganiselo | 90x48x100cm | |||||||

| Ukusinda okushiyekile | 115kg | 120kg | 135kg | 135kg | 140kg | 140kg | 140kg | 150kg |

| Ubunzima bokuthutha | 185kg | 200kg | 215kg | 215kg | 220kg | 220kg | 220kg | 260kg |

Umboniso weMveliso

Isihloko: Esona siKhokelo soMgangatho oPhezulu weTilt-Cast yokuNyibilikisa iiFurnaces zeeMetal ezixabisekileyo

Ngaba ukwimarike yomgangatho ophezulu wokuthambeka okugalela iziko lokunyibilikisa lesinyithi esixabisekileyo? Musa ukuthandabuza kwakhona! Kwesi sikhokelo sibanzi, siza kuphonononga yonke into ekufuneka uyazi malunga nezi ziko zikumgangatho ophezulu, kubandakanya iimpawu zazo, izibonelelo, kunye nendlela abanokuguqula ngayo inkqubo yakho yokunyibilikisa isinyithi esixabisekileyo.

1. Qonda ulwazi olusisiseko lwe-tilt casting induction melting furnace

I-tilt-type yokugalela iziko lokunyibilikisa sisixhobo esiphucukileyo esenzelwe ngokukodwa ukunyibilikisa nokugalela iintsimbi ezixabisekileyo ezifana negolide, isilivere, kunye neplatinam. Ezi ziko zisebenzisa i-electromagnetic induction ukuvelisa ubushushu ngaphakathi kwentsimbi, evumela ulawulo oluchanekileyo lobushushu kunye nokunyibilika okusebenzayo. Isici esithambekileyo senza kube lula ukugalela isinyithi esinyibilikisiweyo kwiziko lokubumba okanye ezinye izikhongozeli, ukwenza inkqubo ingabinamthungo kwaye isebenze kakuhle.

2. Ukubaluleka kolwakhiwo olukumgangatho ophezulu

Xa kuziwa ekunyibilikiseni iintsimbi ezixabisekileyo, umgangatho ubalulekile. Iziko lokunyibilikisa i-tilt-cast induction ephezulu yakhiwe kusetyenziswa izinto ezomeleleyo ezifana nezitena eziphikisayo, intsimbi ekumgangatho ophezulu kunye ne-insulation ephezulu ukuqinisekisa ukugcinwa kobushushu obuninzi kunye nelahleko encinci yobushushu. Oku akugcini nje ukuphucula ukusebenza kakuhle kwenkqubo yokunyibilika kodwa iqinisekisa ixesha elide kunye nokuthembeka kwesithando somlilo.

3. Iimpawu eziphambili emazikhangelwe

Kukho izinto ezininzi ezibalulekileyo ekufuneka ziqwalaselwe xa kuthengwa isithando somlilo esinyibilikisayo. Khangela isithando somlilo esinenkqubo yokulawula ubushushu obuphezulu, indlela echanekileyo yokuthambeka, kunye neempawu zokhuseleko ezifana nokucima okungxamisekileyo kunye nokukhusela ukushisa. Ukongeza, qwalasela umthamo wesithando somlilo sakho ukuqinisekisa ukuba siyahlangabezana neemfuno zakho zemveliso.

4. Iingenelo zokusebenzisa i-tilt casting induction yokunyibilikisa iziko

Ukusetyenziswa kweziko lokunyibilikisa i-tilt-cast induction ekumgangatho ophezulu kubonelela ngeenzuzo ezininzi kumashishini kunye neengcibi ezisebenza ngeentsimbi ezixabisekileyo. Ezi ziko zibonelela ngolawulo oluchanekileyo lobushushu, nto leyo ebangela ukunyibilika okukumgangatho ophezulu, okuhambelanayo. Umsebenzi we-tilt uvumela ukuthululwa okulula kunye nokuchanekileyo, ukunciphisa umngcipheko wokuchithwa kunye nenkunkuma. Ukongezelela, ukusebenza kakuhle kwezi ziko kubangela ukongiwa kweendleko ngokwemigaqo yokusetyenziswa kwamandla kunye nabasebenzi.

5. Izicelo ekwenzeni ubucwebe kunye nokulungiswa kwesinyithi

Iziko lokunyibilikisa le-Tilt-cast cast lisetyenziswa ngokubanzi kwimizi-mveliso yezacholo kunye nentsimbi. Nokuba uligcisa elincinane elenza ubucwebe besiko okanye umenzi omkhulu ovelisa izinto zemizi-mveliso, ezi ziko zibonelela ngokuchaneka kunye nokusebenza kakuhle okufunekayo ukunyibilika nokugalela iintsimbi ezixabisekileyo.

6. Izilumkiso kwiindidi ezahlukeneyo zeentsimbi ezixabisekileyo

Iintsimbi ezixabisekileyo ezahlukeneyo zineendawo ezahlukeneyo zokunyibilika kunye neempawu, ekufuneka zithathelwe ingqalelo xa ukhetha i-tilt-cast induction melting furnace. Umzekelo, igolide kunye nesilivere zineendawo ezisezantsi zokunyibilika xa kuthelekiswa neplatinam kwaye zifuna iziko ezinolawulo oluchanekileyo lobushushu ukuze ufumane iziphumo ezichanekileyo. Qinisekisa ukuba ukhethe isithando somlilo esifanelekileyo kwiintsimbi ezithile ozisebenzisayo.

7. Isondlo kunye nenkathalo

Ukuqinisekisa ubomi obude kunye nokusebenza ngokufanelekileyo kwesithando sakho sokunyibilikisa i-tilt-cast cast, ukugcinwa rhoqo kunye nokugcinwa kubalulekile. Oku kuquka ukucoca isitovu emva kokusetyenziswa ngakunye, ukuhlola nokutshintsha iindawo ezigugileyo, kunye nokulandela izikhokelo zokulondolozwa komenzi. Ngokugcina isithando somlilo sakho ngokufanelekileyo, unokwandisa ubomi baso kunye nokusebenza kakuhle.

8. Tyala kumgangatho wempumelelo yexesha elide

Ngelixa iqondo eliphezulu le-tilt-cast induction melting furnace inokufuna utyalo-mali olubalulekileyo lokuqala, iinzuzo zexesha elide zodlula kakhulu iindleko. Ngokutyala imali kwisithando somlilo esithembekileyo, esisebenzayo, unokulungelelanisa inkqubo yakho yokuvelisa, uphucule umgangatho wemveliso, kwaye ekugqibeleni wandise umgca wakho ophantsi.

9. Khetha umboneleli ofanelekileyo

Xa uthenga i-tilt-cast induction melting furnace, kubalulekile ukukhetha umboneleli othembekileyo nonamava. Khangela umthengisi obonelela ngeziko ezikumgangatho ophezulu, inkxaso ebanzi yabathengi, kunye nerekhodi eqinisekisiweyo yokuhambisa izixhobo ezithembekileyo. Ukongeza, qwalasela izinto ezifana nokhuseleko lwewaranti kunye nenkonzo yasemva kokuthengisa ukuqinisekisa amava okuthenga afanelekileyo.

10. Isiphelo

Isishwankathelo, isithando somlilo sokunyibilikisa esikumgangatho ophezulu siyinto efunekayo kumashishini kunye neengcibi ezisebenza ngeentsimbi ezixabisekileyo. Ngokuqonda iimpawu, izibonelelo, kunye neengqwalasela ezinxulumene nezi ziko ziphambili, unokwenza isigqibo esinolwazi xa ukhetha izixhobo ezifanelekileyo kwiimfuno zakho ezithile. Ngesithando somlilo esifanelekileyo, unokwandisa iinkqubo zakho zokunyibilika kunye nokugalela ukwandisa ukusebenza kakuhle, umgangatho, kunye nempumelelo iyonke yokusetyenzwa kwesinyithi esixabisekileyo.

Yandisa ulwazi lwakho lweplatinam yokunyibilikisa iziko

Isihloko: Isikhokelo esigqibeleleyo sokuqonda iPlatinum Furnace

Ngaba ungumcwebi wezacholo, umsebenzi wesinyithi, okanye umntu onomdla kwinkqubo entsonkothileyo yokunyibilika kweplatinam? Ukuba kunjalo, ufike endaweni elungileyo. Kwesi sikhokelo sibanzi, siza kuntywila kwihlabathi elinomdla leplatinam, sijonge iimpawu zabo, izibonelelo, kunye neziseko okufuneka uzazile ukuze ube nobuchule bokusebenza kweplatinam.

Funda malunga neziko lokunyibilikisa iplatinam

Iyaziwa ngokunqaba kwayo kunye nokuqina kwayo, iplatinam iye yaba sisinyithi esixabisekileyo kangangeenkulungwane. Iipropathi zayo ezizodwa ziyenza ibe lukhetho oludumileyo lobucwebe obuhle, usetyenziso lwamashishini, kunye nezicelo zonyango. Nangona kunjalo, ukusebenza ngeplatinam kufuna izixhobo ezikhethekileyo, kwaye esinye sezona zixhobo zibaluleke kakhulu kule nkqubo sisithando somlilo seplatinam.

Yintoni iziko lokunyibilikisa iplatinam?

Isithando somlilo seplatinam sisixhobo esikhethekileyo esenzelwe ukufikelela kunye nokugcina amaqondo obushushu aphezulu afunekayo ukunyibilikisa iplatinam. Ngokungafaniyo nezinye iintsimbi, iplatinam inendawo yokunyibilika ephezulu kakhulu eyi-3,215.1°F (1,768.4°C), nto leyo eyenza kube nzima ukusetyenzwa kusetyenziswa iindlela zesintu.

Iintlobo zeziko lokunyibilikisa iplatinam

Kukho iintlobo ezininzi zeziko leplatinam ezikhoyo, nganye ineempawu zayo ezizodwa kunye neenzuzo. Ezona ndidi zixhaphakileyo ziquka:

1. Iziko lokungeniswa: Ezi ziko zisebenzisa i-electromagnetic induction ukuvelisa ubushushu ngaphakathi kwiplatinam. Ziyaziwa ngokusebenza kwazo kunye nolawulo oluchanekileyo lobushushu, nto leyo ezenza zibe lukhetho oludumileyo lokunyibilikisa iplatinam.

2. Isithando somlilo sokumelana: Ikwabizwa ngokuba yi-resistance furnace, isebenzisa ukuxhathisa ukuvelisa ubushushu. Zikulungele ukunyibilikisa iimali ezincinci zeplatinam kwaye zihlala zisetyenziselwa ukwenza ubucwebe kunye nentsimbi encinci.

3. IGesi/Iziko Lomlilo: Ezi ziko zisebenzisa idangatye elithe ngqo okanye igesi ukufudumeza nokunyibilikisa iplatinam. Nangona zisebenza kakuhle, azinako ukubonelela ngezinga elifanayo lokulawula ukushisa njenge-induction okanye isithando sokumelana.

Izibonelelo zokusebenzisa iplatinam yokunyibilikisa iziko

Ukusebenzisa iziko leplatinam kuneengenelo ezininzi, kubandakanya:

1. Ukulawulwa kweqondo lokushisa ngokuchanekileyo: I-Platinum idinga ubushushu obuthile bokunyibilika, kwaye isithando somlilo sibonelela ngolawulo oluchanekileyo olufunekayo ukufezekisa iziphumo ezifunwayo.

2. Ukusebenza kakuhle: Iifarnaces zenzelwe ukwanelisa umbane ngokufanelekileyo, ukunciphisa inkcitho kunye neendleko zokusebenza.

3. Ukhuseleko: Ukusebenza ngamaqondo aphezulu kunye nezinyithi ezixabisekileyo kufuna indawo ekhuselekileyo nelawulwayo, apho isithando somlilo sinokubonelela.

4. Ukuhambelana: Isithando somlilo siqinisekisa iziphumo ezihambelanayo, ukudala iimveliso zeplatinum eziphezulu.

Ulwazi olusisiseko lokusebenzisa isithando somlilo seplatinam

Ukusebenzisa isithando somlilo seplatinum kufuna ukuqonda okunzulu kweempawu zetsimbi kunye nezobugcisa bezixhobo. Nazi ezinye iingongoma ekufuneka uziqwalasele:

1. Indawo yokunyibilika: Njengoko bekutshiwo ngaphambili, iplatinam inendawo yokunyibilika ukuya kutsho kwi-3,215.1°F (1,768.4°C). Kubalulekile ukuqonda kunye nokubambelela kwiimfuno ezithile zokushisa zokunyibilikisa iplatinam ukuphepha ukonakalisa isinyithi.

2. Ukukhethwa kwe-crucible: I-crucible okanye isitya sokunyibilikisa iplatinam sidlala indima ebalulekileyo kwinkqubo yokunyibilika. Kubalulekile ukukhetha i-crucible enokumelana namaqondo obushushu aphezulu kunye neekhemikhali ezibandakanyekayo ekunyibilikeni kweplatinam.

3. Izilumkiso zoKhuseleko: Ukusebenza ngamaqondo obushushu aphezulu kunye neentsimbi ezixabisekileyo kufuna ukuthotyelwa okungqongqo kunye nemigaqo yokhuseleko. Izixhobo zokukhusela, ukungena komoya okufanelekileyo, kunye nokuqonda ngokucacileyo ukusebenza kwezixhobo zibalulekile kwindawo ekhuselekileyo yokusebenza.

4. Ucoceko lweMathiriyeli: IPlatinathi isoloko idityaniswe nezinye iintsimbi ukunyusa iimpawu zayo. Ukuqonda ukubunjwa kweplatinam enyibilikayo kubalulekile ekufezekiseni iziphumo ezifunwayo.

5. Ukujongwa kweqondo lobushushu: Ukusebenzisa amandla okulawula ubushushu kwiziko lakho kubalulekile ekugcineni ubushushu obuchanekileyo obufunekayo ukunyibilikisa iplatinam.

Inkosi yobuGcisa bokuNyibilika kwePlatinam

Ukusebenza ngeplatinum kunye neefurnaces sikhono esifuna ulwazi lobugcisa kunye namava asebenzayo. Nokuba uligcisa elinamava okanye umtsha kumsebenzi wesinyithi, ukuba nobuchule bokunyibilikisa iplatinam kuthatha ixesha kunye nokuzinikela.

Nanga amanye amacebiso okukunceda kuhambo lwakho:

1. Imfundo kunye noqeqesho: Tyala ukufunda iipropathi zeplatinam, ukusebenza kwesithando somlilo, kunye nezona ndlela zilungileyo zokusebenza kunye neentsimbi ezinobushushu obuphezulu.

2. Umthambo oSebenzayo: Akukho nto idlula amava asebenzayo. Qala ngeeprojekthi ezincinci ukuze uziqhelanise nenkqubo yokunyibilika, emva koko usebenze indlela yakho ukuya kwimisebenzi enzima ngakumbi.

3. Uphuculo oluqhubekayo: Gcina unolwazi malunga nophuhliso lwamva nje lwethekhinoloji yesithando somlilo kunye neplatinam yokucubungula iteknoloji. Ukufunda rhoqo kunye nophuculo zizitshixo zobuchule bobuchule bobugcisa.

4. Ukusebenzisana kunye nothungelwano: Qhagamshelana nabanye abantu abaqeqeshiweyo kushishino, yiya kwiindibano zocweyo, kwaye ufune amathuba okucebisa ukwandisa ulwazi lwakho nezakhono.

Ukuqukumbela, ukuqonda iziko leplatinam kubalulekile kuye nabani na osebenza ngale ntsimbi ixabisekileyo. Ukusuka kwimiba yobugcisa yezixhobo ukuya kubugcisa bokusebenza kweplatinam, ukubamba lo msebenzi wobugcisa kufuna indibaniselwano yolwazi, ubuchule kunye nokuzinikela. Ngezixhobo ezifanelekileyo kunye nobuchule, unokuvula amandla apheleleyo eplatinam kwaye udale imisebenzi emangalisayo yobugcisa eya kumelana novavanyo lwexesha.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur