Uhlobo lweTonelo yeGolide yeIngot yeVacuum Casting System

Isicombululo Esisengqiqweni

Kwiminyaka edlulileyo, imarike yotyalo-mali yeentsimbi ezixabisekileyo iye yathandeka ngakumbi nangakumbi: ngoku ingot kufuneka ibe neempawu ezifanayo zobuhle belitye elinqabileyo.

Ukusebenzisa oomatshini abakhoyo kwiimarike ngaphambi kokuqaliswa kwe-HS-VF260, umntu unokuvelisa iimveliso ezisemgangathweni ofanelekileyo, kodwa kwakunzima kubaqhubi ukuba balawule. Ngokwenyani, ulungelelwaniso lweeparamitha zomsebenzi kunye nolondolozo lwesiqhelo luphantse lwalinganiselwa kuphela kubasebenzi abazingcaphephe kakhulu.

Ukuqaliswa kwe-HS-VF260 kwaguqula intsimi: iinkampani emhlabeni jikelele zabonelelwa ngeziko ezilungiselelwe i-tunnel, ezinokunyuka ngokweentlobo zemveliso (i-ingot ukusuka kwi-1 ounce, ukuya kwii-ounces ze-400 okanye ii-ounces ze-1000), ukugcinwa kwayo kwafikeleleka.

Ekuphela kwesisombululo yayikukuyila isithando somlilo setonela esine-interface ekulula kunye ne-user-friendly interface (i-HMI touch screen), enokuthi idityaniswe ngokupheleleyo ngesitshixo esinye.

Imiba ebalulekileyo kunye nokungalunganga kweNkqubo yesiNtu

Iziko likwindawo evulekileyo kwaye idangatye lihlala livutha, kungoko imingcipheko yeengozi emsebenzini iphezulu kakhulu.

Imingcipheko ephezulu yokulahleka kwesinyithi.

Ukukhutshwa okubalulekileyo komsi, ukuchacha kwayo kubiza kakhulu kwinkampani, kunye nophuhliso lwendawo eyomeleleyo ye-electromagnetic.

Ubuninzi bezinto ezisetyenziswayo, ezifana ne-crucibles, zisetyenziswa kwaye zigugile ngokukhawuleza, ezithetha iindleko eziphezulu zokusebenza.

Umgangatho we-ingot egqityiweyo (ukukhanya, ukucoceka, ukunyameka) kuphakathi-phezulu.

Isithando somlilo sidinga ubukho rhoqo babaqhubi.

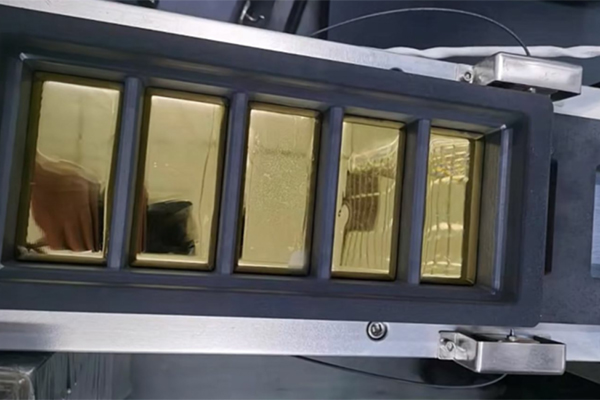

I-Tunnel Furnace Gold Vacuum Casting System

imveliso: iibhloko ezi-4 / iyure, ibhloko nganye inobunzima be-15kg;

Ubushushu bokusebenza okuphezulu: 1350-1400 degrees Celsius;

Uhlobo lwegesi yokukhusela: i-nitrogen; Ukusetyenziswa komoya: 5/H;

Ubushushu bamanzi okungena kwisithando somlilo kunye nejenereyitha: ukuya kuthi ga kwi-21 degrees Celsius;

Ukusetyenziswa kwamanzi ngokupheleleyo: 12-13 / H;

Uxinzelelo lwamanzi okupholisa olufunekayo: 3 ukuya kwi-3,5 bar;

Ukuhamba komoya okufunekayo ukuze kungene umoya: 0.1 m/s;

Uxinzelelo lomoya olufunekayo kwisithando somlilo: ibha ye-6;

Uhlobo lweNgxelo kunye noMahluli: Igraphite 400 oz;

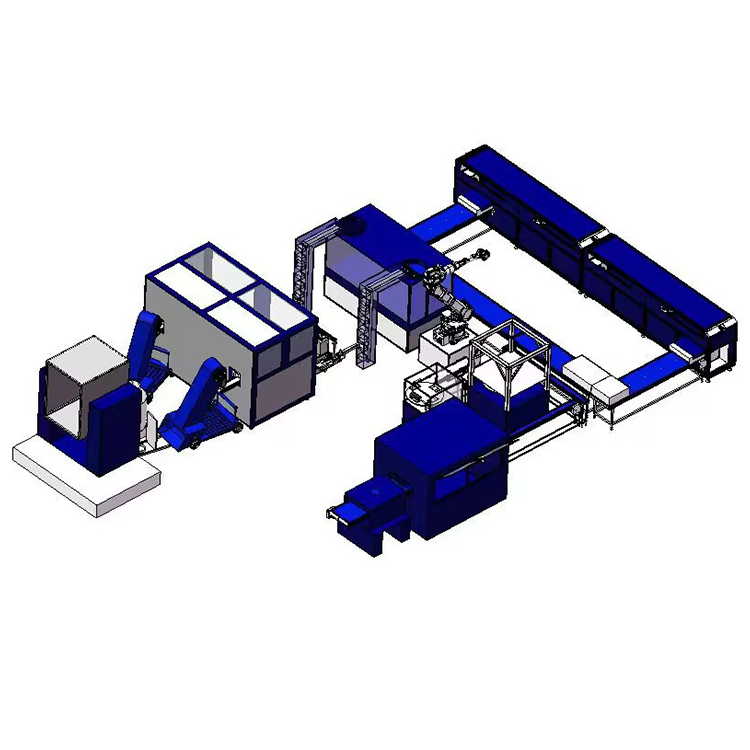

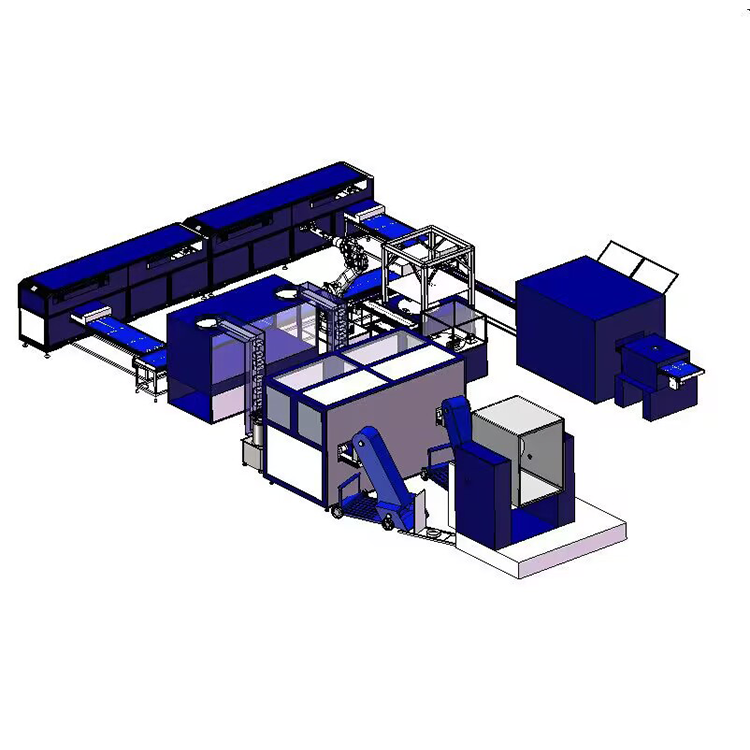

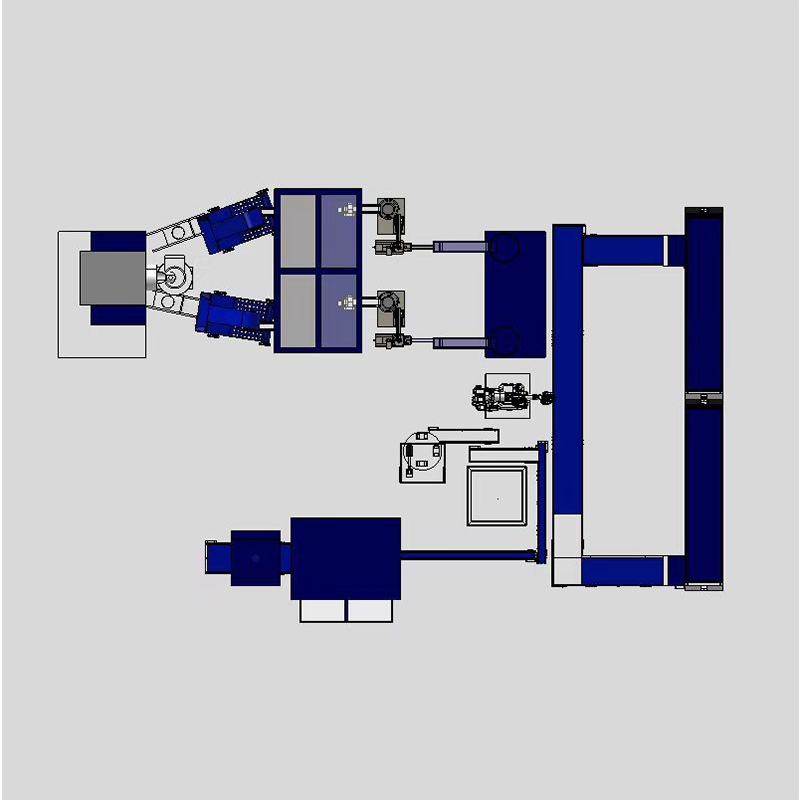

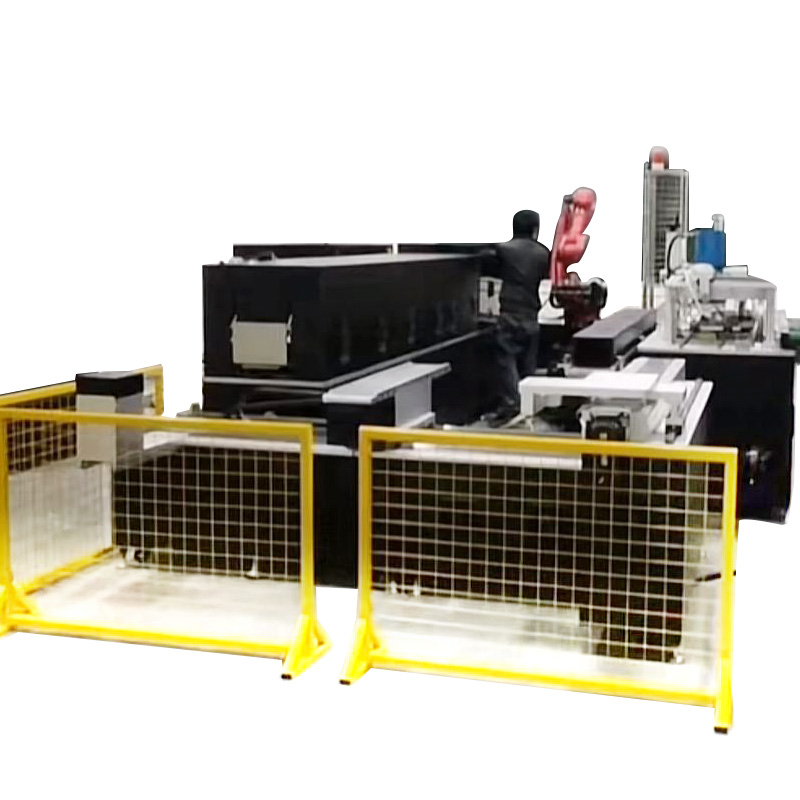

Ummandla opheleleyo wofakelo lwesithando somlilo ngu-18.2M2, ubude buyi-26500mm, kwaye ububanzi buyi-2800mm.

Indawo ekunyibilika kuyo itonela ilawulwa zezi ndawo/iindawo zokusebenzela:

Yenziwe ngentsimbi engenasici. Isicelo: Ukupakisha amasuntswana egolide kumaphepha egraphite. Engundoqo

components: Electric push-step device displacement.

Indawo yokufaka ipharamitha Sebenzisa:

Thintela umoya wangaphandle ukuba ungangeni kwitonela Isixokelelwano sokupholisa: amanzi Amalungu angundoqo: ulwahlulo oluhambayo olunolawulo lwemoya, umbhobho Tofa initrogen.

Usetyenziso lwezowuni yokunyibilika:

esetyenziselwa ukunyibilikisa amasuntswana egolide Isixokelelwano sokupholisa: Amanzi Amalungu angundoqo: i-inductor efakwe isamente erefractory, infrared

Inzwa yobushushu, inkqubo yokuhanjiswa kwenitrogen

Indawo yokupholisa:

isahlulo esinolawulo lwe-pneumatic, umlomo wombhobho Tofa initrogen. kunye ne vacuum.

Indawo yokukhulula:

Yenziwe ngentsimbi engenasici. Injongo:

Khipha imveliso egqityiweyo kwingxelo.

Imodyuli yamandla, iModyuli iyonke: Ukunikezelwa kwamandla: 380v, 50Hz; Izigaba ezi-3 Amandla oMvelisi:

60kW; abanye 20KW. Amandla ewonke afunekayo: 80KW

Indawo yokulawula:

Indawo yokusebenzela kuzo zonke iziko

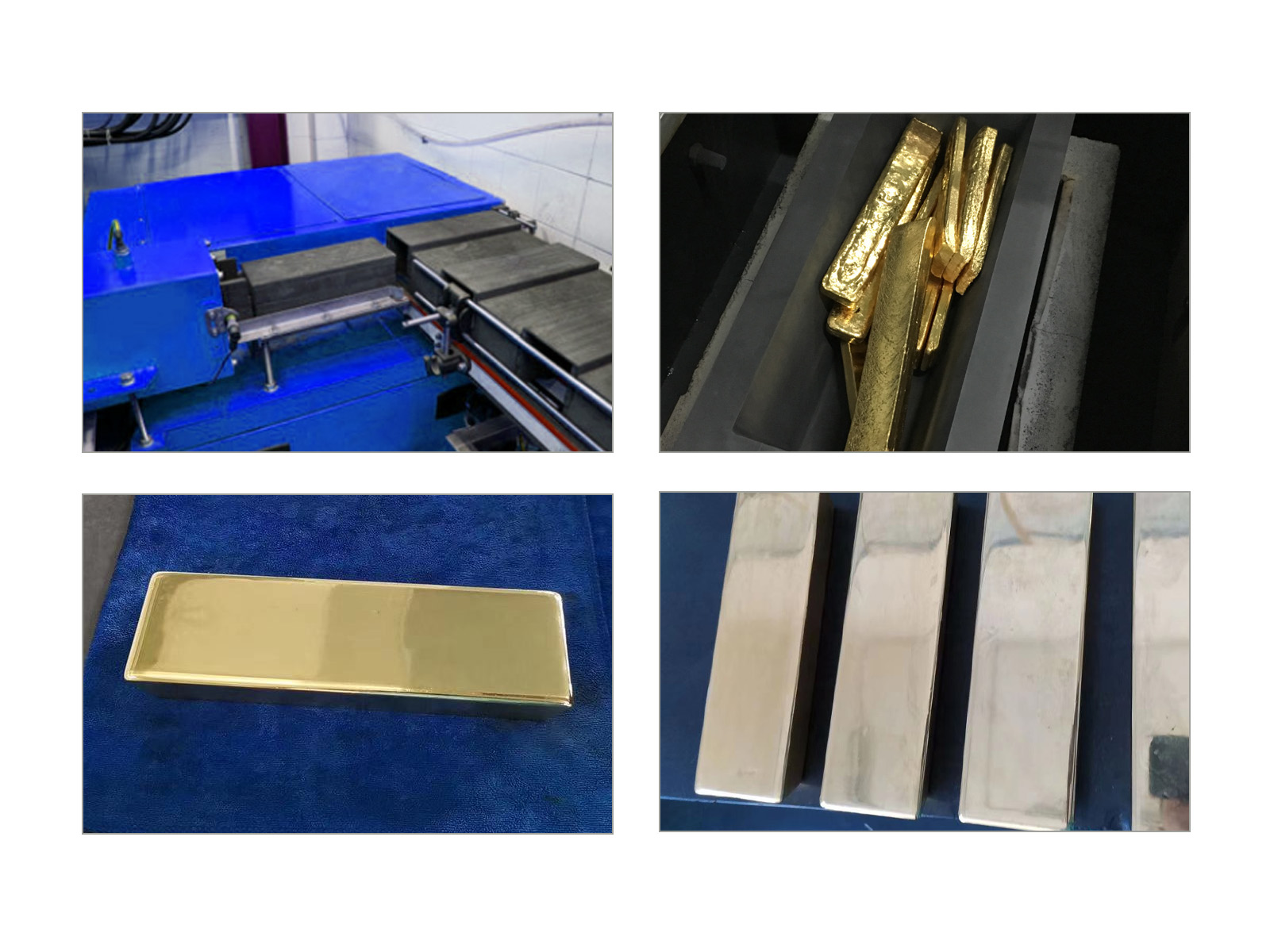

Umboniso weMveliso

Yintoni itonela elipheleleyo elizenzekelayo lomgca wokuvelisa ibha yegolide?

Umgca wemveliso webha yegolide ezenzekelayo ezenzekelayo: ukuguqula ushishino lwegolide

Ushishino lwegolide luhlala luphawu lobutyebi kunye nokuchuma, kwaye imfuno yeebha zegolide iyaqhubeka ikhula. Njengoko iteknoloji ihambela phambili, ukuveliswa kweentsimbi zegolide kuye kwatshintsha kakhulu. Olunye lolona phuhliso luyintshayo kwishishini yilayini yemveliso yegolide yetonela ezenzekelayo. Le teknoloji ye-cutting-edge iguqule indlela eyenziwe ngayo imivalo yegolide, iphucula ukusebenza kakuhle, ukuchaneka kunye nomgangatho. Kweli nqaku, siza kuphonononga ukuba yintoni umgca wokuvelisa ibha yegolide yetonela ezenzekelayo, isebenza njani, kunye nefuthe layo kwishishini legolide.

Yintoni umgca wokuvelisa ibha yegolide yetonela ezenzekelayo ngokupheleleyo?

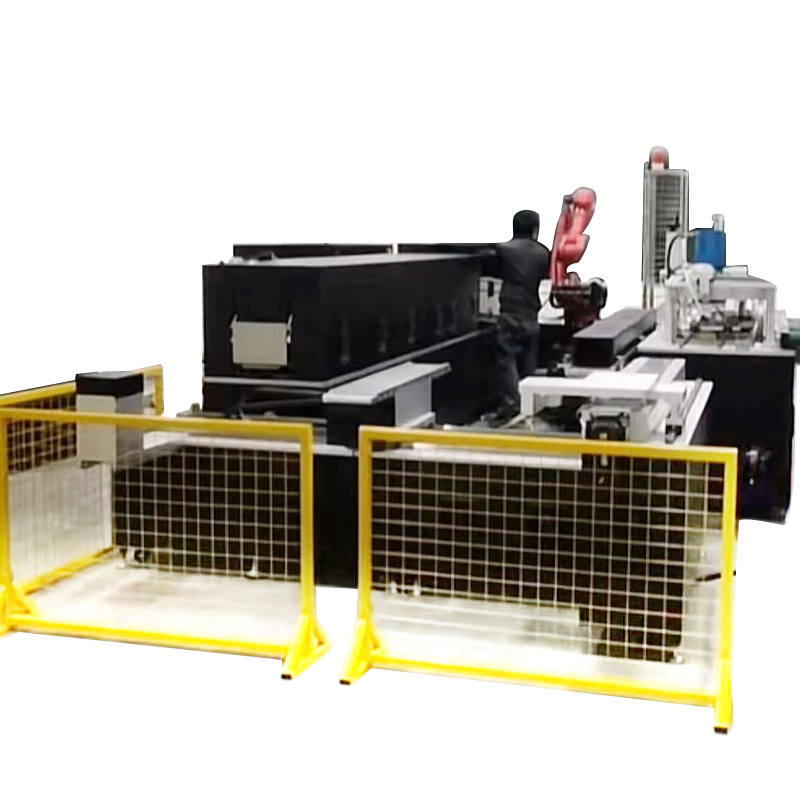

Umgca wemveliso webha yegolide yetonela ezenzekelayo ngokupheleleyo yinkqubo ephucukileyo eyilelwe ngokukodwa ukuveliswa kwebha yegolide ezenzekelayo. Iqulathe uthotho loomatshini abaqhagamsheleneyo kunye nezixhobo ezisebenza ngaphandle komthungo kunye ukuguqula imathiriyeli ekrwada ibe yimivalo yegolide egqityiweyo. Yonke le nkqubo izenzekelayo ngokupheleleyo ngaphandle kokungenelela ngesandla, ukunciphisa kakhulu umngcipheko wephutha lomntu.

Inxalenye ephambili yomgca liziko letonela, eliziko elenzelwe ngokukodwa ukunyibilika nokusulungekisa igolide. Isithando somlilo sixhotyiswe ngenkqubo yokulawula ubushushu obuphezulu kunye neenzwa zokuqinisekisa ukufudumeza okuchanekileyo kunye nokuhambelana kwezinto zegolide. Ukongezelela, umgca wemveliso uquka abathumeli abahlukeneyo, ukubumba, iinkqubo zokupholisa kunye neendlela zokulawula umgangatho wokulungelelanisa yonke inkqubo yokuvelisa.

Umgca wemveliso yebhari yegolide yetonela yegolide ibandakanya

1. Metal granulator

2. I-Sieving nge-vibration system kunye nenkqubo yokomisa

3. Ukutshintshela inkqubo vacuum

4. Inkqubo yokudosa

5. Inkqubo yokugalela ibha yegolide yetonela

6. Ukucoca kunye nenkqubo yokupolisha

7. Inkqubo yokumakisha ichaphaza

8. Logo stamping

9. Inkqubo yokupakisha

Ingaba isebenza kanjani?

Umgca wemveliso wegolide wetonela osebenza ngokuzeleyo usebenza ngokulandelelana kwezigaba ezinxulumeneyo, ngalinye liyilelwe ukwenza umsebenzi othile kwinkqubo yokwenziwa kwebha yegolide. Inkqubo iqala ngokufaka igolide ekrwada kwiziko, apho inyibilikiswa ize icocwe ukuze kususwe ukungcola. Ubushushu kunye nobude bexesha lokufudumeza kulawulwa ngononophelo ukufezekisa ubunyulu obufunwayo kunye nokuhambelana kwegolide etyhidiweyo.

Emva kokuba igolide isulungekisiwe, igalelwa kwimibumba kwaye ibunjwe ngendlela efunwayo yebha yegolide. Iimold ziyilelwe ngokuchanekileyo ukuvelisa izitena zegolide ezinobungakanani obahlukeneyo kunye nobunzima ukuhlangabezana neemfuno ezahlukeneyo zentengiso. Emva kokuba igolide iqinile, ithunyelwa ngenkqubo yokupholisa ukuzinzisa isakhiwo sayo kunye nobushushu.

Ukulawulwa komgangatho kuyinkalo ephambili yomgca wokuvelisa, kunye neenkqubo zokuhlola eziphuculweyo ezidityanisiweyo ukuqinisekisa ukuba imivalo yegolide ihlangabezana nemigangatho ephezulu yokucoceka kunye nomgangatho. Nakuphi na ukutenxa okanye iziphene zichongwa ngokukhawuleza kwaye zisonjululwe, kuqinisekiswe ukuba ziveliswa kuphela izitena zegolide ezigqibeleleyo.

Impembelelo kushishino lwegolide

Ukwaziswa komgca wemveliso wegolide wetonela ozenzekela ngokupheleleyo ube nefuthe elimandla kushishino lwegolide. Obu buchwephesha buphucukileyo butshintshe inkqubo yokwenziwa kwemveliso, buzisa iingenelo ezininzi eziphambili ezilungisa ishishini kwakhona.

Okokuqala nokuphambili, ukuzenzekelayo kweenkqubo zemveliso kwandisa kakhulu ukusebenza kakuhle kunye nemveliso. Ngongenelelo oluncinci lwezandla, umgca unokuqhubeka ngokuqhubekayo, ukwandisa imveliso kunye nokunciphisa ixesha lokuvelisa. Oku kuvumela abasulungeki begolide kunye nabavelisi ukuba bahlangabezane nemfuno ekhulayo yeebha zegolide ngempumelelo nangempumelelo.

Ukongeza, ukuchaneka kunye nokungaguquguquki okuphunyeziweyo ngokuzenzekela kuphucula umgangatho wemivalo yegolide eveliswayo. Iinkqubo zokulawula ubushushu obuphezulu kunye neendlela zokuvavanya umgangatho ziqinisekisa ukuba imivalo yegolide ihlangabezana neyona migangatho iphezulu yokucoceka, ifaka ukuzithemba kubathengi nakubatyalo-mali.

Ukongeza, umgca wemveliso wegolide wetonela ozenzekelayo ngokugqibeleleyo uphucula ukhuseleko kwaye unciphise ifuthe lokusingqongileyo lokwenziwa kwebha yegolide. Ngokunciphisa ukubandakanyeka komntu kwinkqubo yokuvelisa, umngcipheko weengozi kunye nokulimala kuyancipha kakhulu. Ukongezelela, ukusetyenziswa ngokufanelekileyo kwamandla kunye nezibonelelo kwimigca yemveliso ezenzekelayo igalelo kwindlela ezinzileyo kunye neyokusingqongileyo kwimveliso yebha yegolide.

Ngaphaya koko, ukwamkelwa kobu buchwepheshe buhambele phambili kwenza ukuba abavelisi begolide bakhuphisane ngakumbi kwimarike yehlabathi. Ukukwazi ukuvelisa imivalo yegolide ephezulu ngesantya esikhawulezayo kubanika inzuzo yeqhinga, ebavumela ukuba bahlangabezane neemfuno zabathengi bamazwe ngamazwe kunye nokwandisa ukufikelela kwabo kwimarike.

Ngamafutshane, umgca wemveliso wegolide wetonela osebenza ngokuzeleyo ubonisa ukuqhubela phambili okubalulekileyo kushishino lwegolide. Iinkqubo zayo zokuvelisa ezizenzekelayo nezichanekileyo ziphucula ukusebenza kakuhle, umgangatho kunye nokukhuphisana kwemveliso yebha yegolide. Njengoko imfuno yegolide iqhubeka nokunyuka, obu buchwephesha obutsha buya kudlala indima ebalulekileyo ekuhlangabezaneni nemfuno yemarike kunye nokubumba ikamva loshishino lwegolide.

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur