Oomatshini bokuCasa ngoxinzelelo lweVacuum

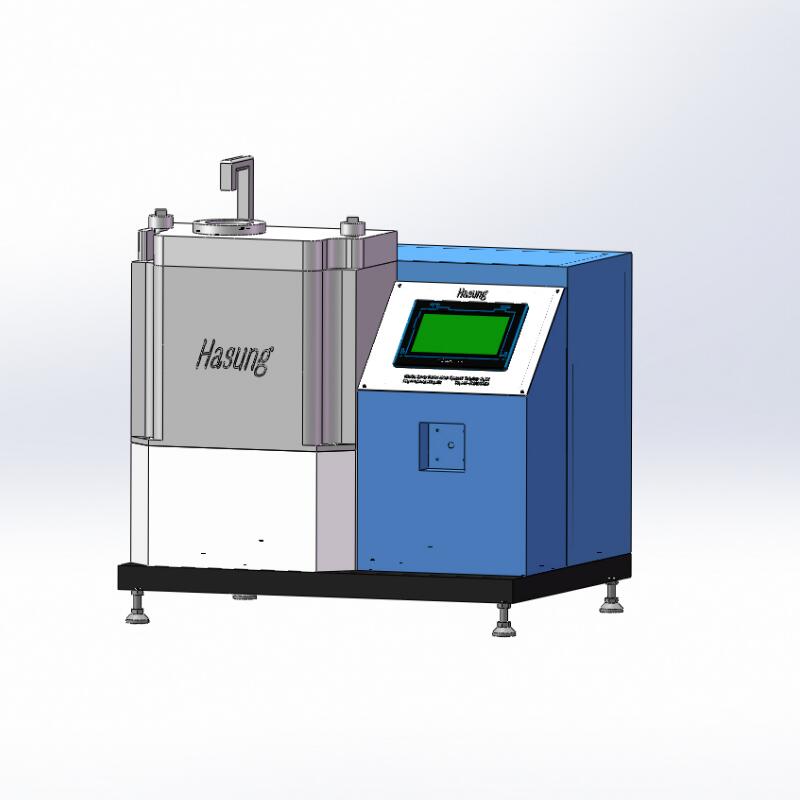

Oomatshini bokuphosa be-HASUNG bafanelekile ukunyibilika kunye nokuphosa iintsimbi zobushushu obunyibilikayo obuphezulu. Ngokutsho kwemodeli, banokuphosa kwaye banyibilike igolide, igolide yeKarat, isilivere, ubhedu, i-alloy kunye ne-TVC, i-VPC, i-VC series, kunye nentsimbi, iplatinam, i-palladium ene-MC series.

Ingcamango esisiseko ye-HASUNG yomatshini wokukhupha uxinzelelo lwe-vacuum kukuvala isigqubuthelo kwaye uqalise ukufudumeza xa umatshini uzaliswe ngezinto zetsimbi.

Ubushushu bunokukhethwa ngesandla.

Izinto eziphathekayo zinyibilika phantsi kwegesi yokukhusela (i-argon / i-nitrogen) ukuphepha i-oxidation. Inkqubo yokunyibilika yayinokubonwa ngokulula ngefestile yokuphonononga. I-crucible ifakwe phakathi kwinqanaba eliphezulu le-air-tight evaliweyo ye-aluminium igumbi kwi-core of induction spool. Okwangoku i-flask enefomu yokuphosa evuthayo ifakwe kwindawo engezantsi yegumbi lokucoca insimbi engenasici. Igumbi le-vacuum lithathiwe kwaye lifakwe phantsi kwe-crucible. Kwinkqubo yokuphosa i-crucible ibekwe phantsi koxinzelelo kunye ne-flask phantsi kwe-vacuum. Umahluko woxinzelelo ukhokelela kwintsimbi engamanzi kwi-ramification egqwesileyo yefom. Uxinzelelo olufunekayo lunokusetwa ukusuka kwi-0.1 Mpa ukuya kwi-0.3 Mpa.

Ivacuum igwema amaqamza kunye ne-porosity.

Emva koko igumbi lokufunxa liyavulwa kwaye iflaski inokukhutshwa.

I-TVC, VPC, VC series machines zixhotyiswe ngeflask lift etyhala iflaski ibheke kwicaster. Oku kwenza kube lula ukususwa kweflask.

Oomatshini bochungechunge be-MC bathambekisa uhlobo lokuphosa i-vacuum, kunye ne-90 degrees ejikayo eyenzelwe ngokukodwa ukuphosa iintsimbi zobushushu obuphezulu. Ithathe indawo ye-centrifugal casting.

-

VCT Series Vacuum Pressure Casting Machine kunye PLC Touch Screen

OKULANDELAYO umatshini woxinzelelo lwevacuum nguHasung ngumatshini wakho olandelayo wokudala umgangatho.

I-1 I-flask yenkxaso kunye ne-flange kunye ne-flask ngaphandle kwe-flange

2. Isantya esihle sokunyibilika, ukonga amandla

3. IGesi ye-Inert - kunye neziqwenga ezilungileyo zokuzalisa

4. Igeyiji echanekileyo enemvakalelo yoxinzelelo ephuculweyo

5. Kulula ukuyigcina

6. Ixesha loxinzelelo oluchanekileyo

7. Ukuzixilonga - I-Taiwan Weinview PLC iphaneli yokuchukumisa i-auto-tuning

8. Kulula ukusebenza, ibhotile enye ukugqiba yonke inkqubo yokuphosa9. Emva kwemowudi ngaphandle kwe-oxidation

10. Ubushushu obuguquguqukayo kwilahleko yegolide

11. Uxinzelelo lwe-vacuum, uxinzelelo lwe-argon, ubushushu, ixesha lokuthulula, ixesha loxinzelelo, ixesha lokucoca.

-

VCTV Series Jewelry Vacuum Pressure Casting Machine kunye System Vibration

OKULANDELAYO umatshini woxinzelelo lwevacuum nguHasung ngumatshini wakho olandelayo wokudala umgangatho.

1. Iimowudi ezimbini zeflask eneflange kunye neflask ngaphandle kweflange

2. Isixokelelwano sokungcangcazela sokuphosa kakuhle

3. Ukuxuba okongeziweyo ukwenzela ukwahlula okulungileyo kwegolide

4. Isantya esihle sokunyibilika, ukonga amandla

5. Igesi ye-inert - kunye neziqwenga zokuzalisa ezilungileyo

6. Igeyiji echanekileyo enemvakalelo yoxinzelelo ephuculweyo

7. Kulula ukuyigcina

8. Ixesha loxinzelelo oluchanekileyo

9. Ukuzixilonga - Japan Mitsubishi PLC iphaneli yokuchukumisa i-auto-tuning

10. Kulula ukusebenza, ibhotile enye ukugqiba yonke inkqubo yokuphosa11. Emva kwemowudi ngaphandle kwe-oxidation

12. Ubushushu obuguquguqukayo kwilahleko yegolide

13. Uxinzelelo lwe-vacuum, uxinzelelo lwe-argon, ubushushu, ixesha lokugalela, ixesha loxinzelelo, ixesha lokucoca, ixesha lokungcangcazela, ixesha lokubamba i-vibration lingamiselwa, Inkqubo yeflask eneflange, inkqubo yeflask ngaphandle kweflange, zombini ziyafumaneka, imowudi ye-auto kunye nemowudi yezandla. ziyafumaneka.

-

TVC Series Induction Vacuum Pressure Casting Machine for Gold Silver Copper

Umatshini wokuLahla ngoxinzelelo olupheleleyo lweVacuum

Itekhnoloji entsha yokuphucula iziphumo zokusa

I-Hasung Casting System

1.Ukuvala isigqubuthelo ngokuzenzekelayo, yonke into isebenza ngokuzenzekelayo ukuphosa ngokubanzi kuphucula ukuhamba kwezinto kunye nokuzaliswa kwesikhunta.

I-2.Castings ibonisa ukuxinana okuphezulu kunye nokuhambelana ngakumbi

3.I-Porosity iyancipha kakhulu

4. Ukumelana noMax. 4 imivalo yokuphosa uxinzelelo.

5. Inkqubo yokusika i-SBS ngaphandle kokusebenzisa i-gaskets, gcina iindleko.

I-6.Castings inoxinzelelo olukhulu kunye neempawu ze-elasticity, okwenza kube lula ukuqhubekeka phambili.

7. Ukusebenza ngokulula kunye nescreen parameter eluncedo

8. Iinkqubo ezili-100 ezikhoyo.

-

VPC Series Vacuum Pressure Casting Machine for Jewellery

Uxinizelelo phezu koomatshini beVacuum Casting

I-VCT lusapho loxinzelelo phezu koomatshini bokugalela bevacuum abayilelwe ukuhlangabezana neemfuno eziqatha ngakumbi ekulahlekeni kwemveliso yewax yegolide, iK-igolide, ubhedu, ubhedu, ialloys. Zihlala zisetyenziswa ngokudityaniswa nomshicileli we-3d wokuphosa ngokuthe ngqo ukufumana iindawo zokuqala zetsimbi zezinto ezinzima.

Olu sapho loomatshini lusebenza ngombono omtsha wegumbi eliphindwe kabini. Le nkqubo ivelisa izinto ezintsha inika uncedo oluninzi xa kuthelekiswa nenkqubo yokufunxa yegumbi elinye ekhoyo ngoku emarikeni.

Kwi-VCT, igumbi elinyibilikayo kunye negumbi le-flask lixhomekeke ngokupheleleyo: ngelixa liphosa, umatshini unokulawula i-injection yesinyithi kwi-mold ngokusebenzisa uxinzelelo oluhlukeneyo ngexesha lokugalela. Oku kuvelisa inaliti ekhawulezayo xa kuthelekiswa nomxhuzulane olula wokugalela kunye nenzuzo yokuphosa izinto kwiqondo lobushushu elisezantsi. Oku kuya kubangela ukugqitywa komgangatho ongcono kunye nokunciphisa i-shrinkage yeendawo zokuphosa.Umjikelo wokuphosa uthatha imizuzu embalwa kuphela kwaye, ngelixa i-flask yangaphambili ipholisa phantsi kwigesi ekhuselayo yokungabikho kwe-oxidation, intlawulo elandelayo inokulayishwa kwi-crucible kwaye inyibilike, ngaloo ndlela igqithise imijikelo emibini ngaphandle kokuchitha ixesha.

Lo matshini uzenzekela ngokupheleleyo, unenkqubo yokubeka iliso esekwe kwiPC ekufumaneni iiparamitha zenkqubo kunye nolawulo lwedatha yemveliso, ngokuhlelwa lula kweenkqubo zokuphosa ezifanelekileyo kuninzi lwe-alloy.

Lo matshini wohlaziyo ludityaniso lweyona njineli iphambili kunye neminyaka yamava ekusasazeni eza kuzisa iHasung kuphela kumzi-mveliso wakho.

-

IHasung T2 Jewelry Vacuum Pressure Casting Machine

OKULANDELAYO umatshini wokulahla uxinzelelo lwevacuum nguHasung ngumatshini wakho olandelayo wokudala umgangatho.

T2 iingenelo:

1. Emva kwemowudi ngaphandle kwe-oxidation

2. Ubushushu obuguquguqukayo kwilahleko yegolide

3. Ukuxuba okongeziweyo ukwenzela ukwahlula okulungileyo kwegolide

4. Isantya esihle sokunyibilika

5. I-De-Gas - kunye neengcezu ezilungileyo zokuzaliswa kweentsimbi

6. Igeyiji enaliti echanekileyo ephindwe kabini kunye nemvakalelo yoxinzelelo ephuculweyo

7. Kulula ukuyigcina ngelixa uphosa

8. Ixesha loxinzelelo oluchanekileyo

9. Ukuzixilonga - i-PID auto-tuning

10. Inkumbulo yeparamitha yeyona ndlela ibalaseleyo yokusaswa

11. Isixokelelwano sokuphosa Inkqubo yokukhupha uxinzelelo lweVacuum - max. uxinzelelo 0.3MPa ngetanki yegesi yangaphakathi

12. Ukutshintsha irhasi enye (iArgon)

13. Inkumbulo yeNkqubo 100 iinkumbulo

14. Ukulawula Ulawulo lwe-microprocessor oluyilwe ngokukodwa. Ulawulo lobushushu ngePID ngokuchaneka kwe +/-1 degrees centigrade.

15. Ukufudumala Ukufudumala Ukufudumala (kunye nentsimbi eyenzelwe ngokukodwa umsebenzi wokuvuselela). -

Umatshini wokuCasa ngoxinzelelo oluncinci lwePlatinam yePalladium yentsimbi yeSilivere yeSilivere

Iintsimbi zeHasung ezixabisekileyo SVC/MC Equipment benefits

Uluhlu lwe-SVC / MC luninzi kakhulu ngoomatshini bokuphosa abafanelekileyo kuluhlu olubanzi lwezicelo zokwenziwa kwesinyithi - kunye nenani leenketho ezazithathwa njengezingahambelaniyo ukuza kuthi ga ngoku. Ngaloo ndlela, ngelixa uchungechunge lwe-MC lwaluyilwe ekuqaleni njengomatshini wokushisa ophezulu wokuphosa intsimbi, i-palladium, i-platinum njl. intsimbi, i-alloy kunye nezinye izinto.

Lo matshini udibanisa inkqubo yoxinzelelo lwamagumbi amabini kunye nesixhobo sokuthamba. Inkqubo yokuphosa iphunyezwa ngokujikeleza yonke iyunithi yokunyibilika kwe-melting-casting nge-90 °. Enye inzuzo yenkqubo yokuthamba kukusetyenziswa kweegrafu zexabiso lezoqoqosho okanye iicrucibles ze-ceramic (ngaphandle kwemingxuma kunye neentonga zokutywina). Ezi zithanda ukuba nobomi benkonzo obude. Ezinye ii-alloys, ezifana ne-beryllium yethusi, zibangela ngokukhawuleza ukuba ii-crucibles ezinemingxuma kunye neentonga zokutywina zingabonakali kwaye ngoko zingenamsebenzi. Ngesi sizathu, ii-casters ezininzi ukuza kuthi ga ngoku zicubungule iialloyi ezinjalo kuphela kwiinkqubo ezivulekileyo. Kodwa oku kuthetha ukuba abanakukhetha ukwandisa inkqubo ngoxinzelelo olugqithisileyo okanye i-vacuum.

-

I-Tilting Vacuum Pressure Casting Machine yePlatinam yePalladium yeGolide yeSilivere yeSilivere

Izibonelelo zeHasung zeZinyithi ezixabisekileyo

Imveliso inombala ofanayo kwaye akukho lucalucalulo:

I-porosity iyancitshiswa, kwaye ubuninzi buphezulu kwaye buhlala buhlala, bunciphisa umsebenzi we-post-processing kunye nokunciphisa ilahleko.

Ubumanzi obungcono bezinto kunye nokuzaliswa ngundo, umngcipheko ophantsi womdla:

I-Vibration iphucula ukuhamba kwezinto, kwaye isakhiwo sezinto eziphathekayo sihlangene ngakumbi. Ukuphucula ukuzaliswa kwemilo kunye nokunciphisa umngcipheko wokuqhekeka okushushu

Ubungakanani beenkozo buncitshiswe ukuya kuma-50%:

Qinisekisa ngesakhiwo esicolekileyo nesifanayo

Iipropati zemathiriyeli ezingcono nezizinzileyo:

Amandla e-tensile kunye no-elasticity anyuswe ngama-25%, kwaye ukusebenza kokucubungula okulandelayo kuphuculwe.

Umbuzo: Yintoni indlela yokuGaba iVacuum?

Ukuchithwa kotyalo-mali, okuhlala kubizwa ngokuba yi- lost-wax castings, zizinto zetsimbi eziveliswa yinkqubo yokutshala imali. Le nkqubo yokubumba echithwayo kunye nezinto eziveliswayo zithandwa kakhulu kwizicelo ezingenakubalwa kumashishini amaninzi. Oku kubangelwa ubukhulu becala into yokuba inkqubo yokuphosa utyalo-mali yenza kube lula ukwenza iindawo ezintsonkothileyo ezineempawu ezibalaseleyo zomphezulu kunye nokuchaneka kuluhlu olubanzi lwezinto kunye nobukhulu. Nangona kunjalo, ukuba inxalenye idinga iinkcukacha eziyinkimbinkimbi okanye i-undercuts, izinto eziphathekayo ziqiniswa ngefiber okanye ucingo, okanye ukungena emoyeni kuyingxaki, kusetyenziswa uhlobo oluthile lwendlela yokutshala imali. Le ndlela yokuphosa utyalo-mali ayikho enye ngaphandle kwendlela yokukhupha i-vacuum, evelise i-vacuum castings. Yintoni i-vacuum castings? Qhubeka ufunda ukuze ufumane.

Yintoni iVacuum Investment Castings?

I-vacuum castings zizinto zentsimbi eziveliswa yindlela yokukhupha i-vacuum. Ziyahluka kunezotyalo-mali eziqhelekileyo ngenxa yobuchule obusetyenziselwa ukwenza ezi nxalenye zetsimbi. Inkqubo iqala ngokubeka iqhekeza le-plaster mold kwigumbi le-vacuum. Ivacuum itsala isinyithi esinyibilikisiweyo kwisingundo. Ekugqibeleni, i-casting iqiniswa kwi-oven kwaye isikhunta siyasuswa ukuze kukhululwe imveliso yokugqibela.

Ukuba uneprojekthi efuna utyalo-mali oluphezulu lwevacuum yobucwebe okanye ezinye iintsimbi, sinokukubonelela ngazo. Apha e-Hasung, sisebenzisa zombini iindlela zomxhuzulane kunye neendlela zokukhupha ivacuum ukuvelisa igolide, isilivere, iplatinam, izinto zentsimbi ezinoluhlu. Iminyaka yethu engenakubalwa yamava kuzo zombini ezi ndlela iqinisekisa ukuba sinokubonelela ngeendawo eziphezulu okanye ezikufutshane nemilo yenetha ezifuna umsebenzi omncinci okanye ongagqitywanga kwaphela. Fumana utyalo mali olufunayo, luziswe ngexesha nangexabiso elikhuphisanayo, ngokuqhagamshelana nathi namhlanje!

Umbuzo: Indlela yokwenza ubucwebe?

Ubucwebe bokuphosa yinkqubo yokwenza iziqwenga zobucwebe ezibandakanya ukugalelwa kwengxubevange yesinyithi elulwelo kwisingundo. Ngokuqhelekileyo kubhekiselwa njengokuphosa kwe-wax elahlekileyo ngenxa yokuba ukubunjwa kwe-wax kwenziwa kusetyenziswa imodeli ye-wax enyibilikayo ukushiya igumbi elingenanto phakathi kwesikhunta. Ubuchwephesha busetyenziswe kangangamawaka eminyaka, kwaye lusasetyenziswa ngokubanzi namhlanje ngabo bobabini abachwephesha abanobuchule kunye nabachwephesha basekhaya ukwenza ukuveliswa okuchanekileyo kwamaqhekeza anqabileyo anqabileyo. Ukuba unomdla ekudaleni ubucwebe bakho usebenzisa ubuchule bokuphosa, landela la manyathelo ngendlela yokwenza ubucwebe.

1. Ukuyila uMngundo wakho

1) Qhawula iqhekeza lewax elukhuni yokwenza imodeli kwimilo oyifunayo. Qala ngokulula okwangoku, njengoko ukubumba okuntsonkothileyo kunzima kakhulu ukukugcina kunye ekuqaleni. Fumana iqhekeza lewax yomzekelo kwaye usebenzise imela echanekileyo, iDremel, kunye nasiphi na esinye isixhobo esifunekayo ukwenza imodeli yobucwebe bakho. Nokuba yeyiphi imilo oyenzayo ngoku iya kuba yimilo yesiqwenga sakho esigqityiweyo.

Wenza umfanekiso ochanekileyo wobucwebe bakho.

Ukusebenzisa iqhekeza lezacholo oyithandayo njengemodeli kuya kukunceda uyile iziqwenga ezingcono xa uqala.

2) Qhoboshela i-3-4 "i-sprues," iingcingo ze-wax eziza kunika umjelo wokuba i-wax inyibilike kamva. Usebenzisa iwax eyongezelelekileyo, yenza izinto ezininzi ezinde, iingcingo eziphuma kwiwax kwaye uzincamathele kwimodeli ukuze zonke zikhokele kude neqhekeza. Oku kulula ukuyiqonda xa ubona yonke inkqubo-le wax iya kugqunywa kwi-plaster, emva koko inyibilike ukwenza inguqu engenanto yesimo sakho. Emva koko uzalise inxalenye egobileyo ngesilivere. Ukuba awuwenzi umthi, umthwebeba onyibilikisiweyo awunakuphuma wenze umngxuma.

Ngamaqhekeza amancinci, njengeringi, unokufuna i-sprue enye kuphela. Iziqwenga ezinkulu, njengeebhanti zebhanti, zinokufuna ukuya kwishumi.

Zonke iisprues kufuneka zihlangane kwindawo enye. Kuya kufuneka ukuba zifakwe kwisiseko se-sprue.

3) Qhoboshela isikhunta kwisiseko se-sprue usebenzisa irubha enyibilikisiweyo. I-sprues zonke zidibana kunye, kwaye unamathele ukungunda kwisiseko se-sprue apho zonke i-sprues zidibana khona. Oku kuvumela i-wax ukuba inyibilike ngaphantsi kwesiseko kwaye ishiye isikhunta.

4) Beka i-flask phezu kwesiseko se-sprue, uqinisekise ukuba unekota ye-intshi phakathi kodonga lweflask kunye nemodeli. Iflaski sisilinda esikhulu esityibilika phezu kwesiseko se-sprue.

2. Ukutyala imali kwi-Mold

1) Khusela imodeli ye-wax ukuya ezantsi kweflask yokuphosa, usebenzisa i-wax enyibilike ngakumbi. Imodeli kufuneka ixhonywe phezulu kwiflask. Ilungele inkqubo yokuphosa ubucwebe.

Qaphela: Kwividiyo, iinxalenye zesilivere ezingaphezulu zezinye iziqwenga zobucwebe ezihamba kunye nebhanti. Ayizozihluzi ezongezelelweyo okanye izongezo eziyimfuneko.

2) Hlanganisa izithako ezomileyo ze-gypsum plaster-based mold mold material ngamanzi, ngokwemiyalelo yomenzi. Landela imiyalelo yalo naluphi na uhlobo lotyalo-mali olukhetha ukuyithenga—kufuneka ibe yimilinganiselo elula.

Nxiba imaski okanye isixhobo sokuphefumla xa kunokwenzeka njengoko usebenza nalo mgubo-akukhuselekanga ukuphefumla.

Qhubeka xa sele unomxube wokuhambelana kwe-pancake batter.

3) Beka isikhunta sotyalo-mali kwindawo yokucoca ukususa nayiphi na i-bubbles emoyeni. Ukuba awunayo ivacuum sealer, ungayiyeka ihlale imizuzu eyi-10 ukuya kwengama-20. Amaqamza omoya aya kudala imingxunya, enokuvumela intsimbi ukuba ingene kwaye yenze isacholo esiphawulweyo sokugqibela.

4) Galela umxube we-investment mold kwi-flask, ujikeleze imodeli ye-wax. Uya kugquma ngokupheleleyo isikhunta sakho kwi-plaster. Phinda uthambise umxube ukuze ukhuphe amaqamza okugqibela, amancinci ngaphambi kokuba uqhubeke.

Songa umaleko wempompo ujikeleze umphezulu weflaski, ukuze isiqingatha seteyiphu sihlale phezu komlomo kwaye sincede ukuqulatha udaka lungabhubhi.

Vumela ukubumba kotyalo-mali ukuseta. Landela imiyalelo echanekileyo kunye nexesha lokumisa lomxube wakho we-plaster phambi kokuba uqhubeke. Xa ugqibile, susa iteyiphu kwaye ukhuhle nayiphi na i-plaster engaphezulu ukusuka phezulu kwi-mold.

I-5) Beka yonke i-flask kwi-oven isete malunga ne-1300 degrees F (600 degrees C). Qaphela, iiplaster ezahlukeneyo zinokuba namaqondo obushushu ahlukeneyo. Nangona kunjalo, akufanele ube nantoni na engaphantsi kwe-1100. Oku kuya kuqina isikhunta kwaye kunyibilike i-wax kude, kushiye igumbi elingenanto embindini we-mold jewelry mold.

Oku kungathatha ukuya kwiiyure ezili-12.

Ukuba une-electronic kiln, zama ukuseta ukuze unyuse kancinci ubushushu ukuya kutsho kwi-1300. Oku kunokunceda ukuthintela ukuqhekeka.

6) Susa i-flask kwi-oven ngelixa ushushu, kwaye ukhangele umzantsi we-mold for obstructions. Qinisekisa ukuba i-wax eshushu inokuvuza ngokulula kwi-mold, kwaye akukho nto iyithintelayo. Ukuba akukho nto endleleni, vuthulula i-flask ngobunono ukuze uqinisekise ukuba yonke i-wax yaphuma. Kufuneka kubekho idama lewax kwireservoir yeflask okanye emazantsi ehontini.

Qinisekisa ukuba unxibe iiglavu zokhuseleko kunye nezibuko.

3. Ukuphosa ubucwebe

I-1) Beka isinyithi sakho esikhethiweyo kwi-crucible crucible, uze unyibilike ngaphakathi kwisiseko. Ubushushu obunyibilikayo kunye nexesha liya kumiselwa luhlobo lwentsimbi oyisebenzisayo. Unokusebenzisa itotshi yokuvuthela kunye ne-crucible encinci yokunyibilikisa isilivere yakho. Oku kugalelwa ngesandla uhlobo ukugalela ngenjongo imveliso encinane.

2) Sebenzisa i-jeweler's vacuum type casting (i-Vacuum Pressure Casting Machine) ukugalela isinyithi kwi-mold. Kwizacholo zobuchwephesha, uya kufuna umatshini wokugalela wohlobo lwevacuum onerhasi engasebenziyo ukuze ukhuseleke. Oku kusasaza isinyithi ngokukhawuleza, kodwa ayisiyiyo kuphela inketho onayo yokuphosa. Esona sisombululo silula, kukugalela nje isinyithi ngononophelo kwitonela eshiywe ngesiseko sobumba.

Ungasebenzisa isirinji enkulu, enentsimbi ethile ukumpompa isinyithi ekubumbeni, nayo.

3) Vumela intsimbi ukuba ipholise imizuzu emi-5-10, uze uyifake kancinci emanzini abandayo. Ubungakanani bexesha elifunekayo ukupholisa lixhomekeke, ngokuqinisekileyo, kwintsimbi enyibilikisiweyo kwaye isetyenziswe. Dunk ngokukhawuleza kwaye isinyithi sinokuqhekeka-dunk emva kwexesha kwaye kuya kuba nzima ukususa lonke udaka kwintsimbi eqinile.

Jonga amaxesha okupholisa intsimbi yakho phambi kokuba uqhubeke. Oko kuthethiweyo, ukuba ukwi-pickle ungalinda nje imizuzu eyi-10 kwaye ugalele emanzini abandayo.

Udaka kufuneka luqalise ukunyibilika njengoko ulushukumisa emanzini abandayo.

4) Thepha ngokuthambileyo isikhunta ngehamile ukuze uqhekeze naluphi na udaka olungaphezulu kwaye utyhile ubucwebe. Yahlula i-flask kwisiseko se-sprue kwaye usebenzise iminwe yakho okanye ibhrashi yamazinyo ukukhupha nayiphi na into yokugqibela enamathele kubucwebe.

4. Ukugqiba ubucwebe bakho

1)Sebenzisa i-engile grinder enevili elisikiweyo ukusika nayiphi na imigca yentsimbi kwi-sprues. Sika iingceba ezicekethekileyo zentsimbi obuzifuna ukwenza umngxuma wokugalela intsimbi. Igrinder ephathwa ngesandla kufuneka yomelele ngokwaneleyo.

2) Qwalasela kunye nokuhlamba ngeasidi okanye ukuhlamba ukucoca nayiphi na into yokugqibela yodaka. Inkqubo yokudubula ihlala ishiya isinyithi simdaka kwaye simdaka. Unokujonga kwiindawo zokuhlambela ezithile zesinyithi ezithile, eziya kukhokelela ekukhanyeni okuhle kakhulu kunye nomsebenzi olula wokucoca isiqwenga kamva.

3) Susa naziphi na izitenxo kwisiqwenga sobucwebe usebenzisa ivili lentsimbi. Sebenzisa iifayile, iimpahla ze-enamel, iipolishi, njl.njl. ukucoca isiqwenga ukuya kwisitayile osifunayo. Ukuba ucebe ukuseta ilitye, yenze emva kokugqiba ukupolisha.