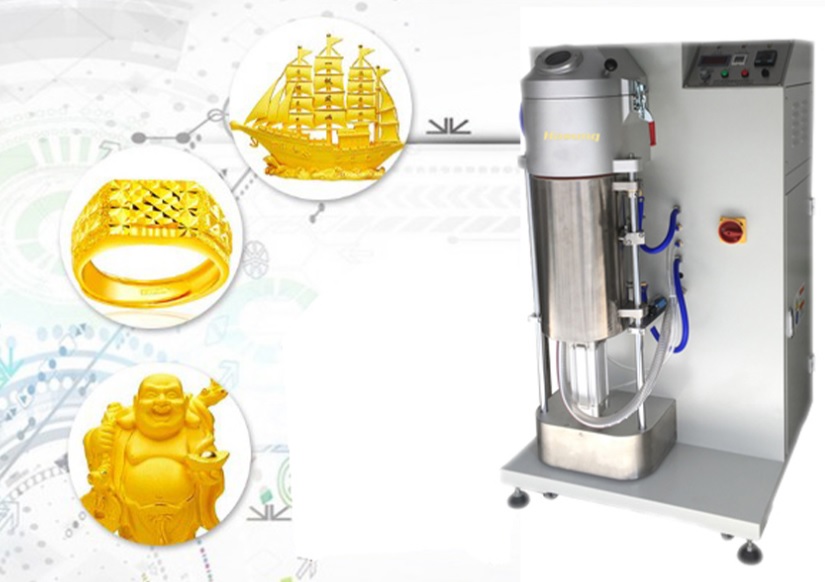

Ivacuum yegolide / yesilivereumatshini wokuphosa ubucwebeyenzelwe ukwenza ubucwebe. Lo matshini uyilelwe ukuhlangabezana neemfuno eziqatha ngakumbi kwimveliso yokugalela umthwebeba. Lo matshini usebenza ngeekhonsepthi ezintsha kwaye uneengenelo ezininzi xa kuthelekiswa nabanye oomatshini abaqhelekileyo. Inzuzo yomatshini wokucoca izacholo ngaphezulu koomatshini abaqhelekileyo zezi zilandelayo:

Ngokuthelekisa indawo eninzi yokugalela ngentsimbi

Yethuumatshini wokwenza ubucwebeinendawo ngokuthelekisayo xa kuthelekiswa nabanye oomatshini bentsimbi. Ukuba ukuphosa kwenziwa ngokuba nezixa ezincinci zetsimbi ngexesha, ke, kuya kuthatha ixesha elininzi ukuthoba imveliso.

Ukunyibilika kwevacuum kunye nokuphosa zombini kwenziwa kumatshini omnye

Koomatshini abaqhelekileyo ukunyibilika kwesinyithi kunye nokuphosa kwenziwa koomatshini abahlukeneyo abathoba ubungakanani bemveliso njengoko ezinye zobuninzi zilahlekile ekudluliseleni into etyhidiweyo ukusuka komnye umatshini ukuya komnye. Kodwa kumatshini wethu, zombini iinkqubo zenziwa kumatshini omnye oshiya imfuno yokuhambisa ubunzima obutyhidiweyo ukusuka komnye umatshini ukuya komnye okukhokelela ekwandiseni isivuno.

Ibonelela ngekhwalithi yentsimbi

Nangona ukuphoswa kwentsimbi akuqinisekiswanga kubo bonke oomatshini. Abanye oomatshini bayishiya intsimbi ingashukumi ngokupheleleyo nto leyo ekhokelela kwiziphumo ezikumgangatho ophantsi. Kodwa umatshini wethu wokulahla intsimbi ubonelela ngeemveliso ezisemgangathweni, kwaye uqinisekisa umgangatho ukuba ube ngowona ubalaseleyo kwiimveliso zethu. Inkqubo yokuphosa iphantsi kwemeko yoxinzelelo ukuze ikhuthaze ukugcwaliswa kwe-mold kubuninzi. Ubucwebe obugqityiweyo bunesithando somlilo esigudileyo, ukuxinana okuphezulu kwaye akukho bubble emoyeni.

Ukuvuselela okuqinileyo ukuqinisekisa umbala olinganayo

Kumatshini wokunyibilika wesinyithi kunye nokuphosa, ukuvuselela yinto ebalulekileyo. Oomatshini bokuphosa besinyithi abaqhelekileyo banezinga eliphantsi lokushukumisa elishiya imveliso kwithoni engalinganiyo. Ubucwebe benziwe ngethoni engalinganiyo kunye nombala ngokuqinisekileyo bubukeka bungathandeki.Umatshini wethu osanda kuyilwa kunye nomgangatho ophezulu wokuphosa ubucwebe uqinisekisa ukuvuselela rhoqo. I-Electromagnetic stirring isetyenziswa kulo matshini oqinisekisa umbala olinganayo.

Isilinda sokuphosa esisodwa esahlulwe kwisixhobo sokufunxa

Nangona ukunyibilika kunye nokuphosa kwenziwa kumatshini ofanayo kodwa iisilinda zeenkqubo zombini zigcinwa zahluliwe ukugcina umatshini usebenza ngokukhawuleza kwaye ngokuzimeleyo. Injongo yokugcina zombini ezi nkqubo zahlukeneyo kukuzigcina zilungile ngokomgangatho. Ukuba zenziwe zidityanisiwe ke zombini iinkqubo zichaphazela enye kwenye.

Uyilo oluqinileyo

Ngenxa yoyilo lwawo oludibeneyo, umatshini wethu ufuna indawo encinci yokufakelwa. Uyilo oluncinci kunye nolubambeneyo luyenza isebenziseke kuzo zonke iintlobo zengingqi nokuba kumashishini amakhulu okanye amancinci. Kwakhona umsebenzi wamashishini amabini ahlukeneyo wenziwa kumatshini omnye oneesilinda ezimbini ezahlukeneyo, ngoko kukho inzuzo eyongezelelweyo yokusetyenziswa kwendawo encinci.

Inkqubo yealam

Ii-alamu ezahlukeneyo ziye zadityaniswa kumatshini ukumisa inkqubo yokunyibilika kunye nokuphosa kumatshini ngokukhawuleza ukuphepha nayiphi na ilahleko. Esi sixokelelwano se-alam sigcina isixokelelwano sakho kude kulo naluphi na uhlobo lokwenzakala kumatshini onokuthi lwenzeke ngenxa yokuvalelwa kwenkqubo enye. Yongeza ekusebenzeni kakuhle kwenkqubo.

Inkqubo yokuphosa ngokukhawuleza

Njengoko lo matshini uxhasa ubuninzi bentsimbi (igolide) ngexesha, uqinisa umlinganiselo wemveliso. Kwakhona iisilinda ezimbini ezahlukeneyo zokwenza ukuphosa kunye nokunyibilika ngaphandle kwenza ukuba ukusebenza kube ngcono kukhokelela kwisivuno esingcono.

Inkqubo yokulawula ubushushu bePID

Inkqubo yokulawula iqondo lokushisa igcina umatshini wokuphosa ubucwebe be-vacuum ekunyuseni ubushushu ukuya kuthi ga kwinqanaba elinokuba yingozi kumatshini okanye elingafanelekanga kwinkqubo yokunyibilika kwesinyithi kunye nokuphosa. Ubushushu obuphezulu abukho bungozi kumatshini wokufunxa nje kuphela kodwa bukwabilisa intsimbi ebiza kunyibilikiswa ize ke intsimbi yonakale. Umatshini wethu wokufunxa unamandla okunyamezela ubushushu obuyi-±1°C kunye nomthamo omkhulu wobushushu obuyi-1600°C.

Ukhetho oluzenzekelayo kunye ne-semi-auto olukhoyo

Amaxesha amaninzi abasebenzi bayafuneka ukuze baqhube oomatshini, kwaye kufuneka babe kufutshane nomatshini ukuthintela nawuphi na umonakalo kumatshini, okanye ukoyisa iimeko ukuba umatshini awusebenzi kakuhle. Oku kufuna inani elikhulu labasebenzi ukujongana nokusebenza kwenani elikhulu loomatshini kwishishini. Umatshini wethu osanda kuyilwa wokwenza ubucwebe bezacholo zevacuum uyilelwe ukusebenza phantsi kwazo zonke iimeko. Ibonelelwa ngokhetho oluzenzekelayo kunye ne-semi-automatic ukuphatha umatshini ngaphandle kwabasebenzi abongezelelweyo. Useto lwe-semi-automatic lunokulungelelaniswa njengoko lufunekayo ukwenza umatshini usebenze njengoko ufuna. Oku kunciphisa isidingo sabasebenzi abongezelelweyo ukukhathalela oomatshini. Iingenelo ezinkulu zomatshini wethu wokuphosa ubucwebe bezacholo zininzi xa kuthelekiswa noomatshini abanyibilikayo besinyithi abaqhelekileyo kunye nokuphosa. Yonyusa izinga lemveliso kunye nesivuno ngokubanzi kwaye inciphisa iindleko zabasebenzi, kungoko yenza inzuzo enkulu kwishishini lakho. Kwaye ibonelela ngeemveliso ezikumgangatho ophezulu ezinokonyusa abathengi bakho kwihlabathi liphela. Lo matshini uluncedo kakhulu ungqineke ufanelekile ukuba nawo.

Ngolwazi oluthe vetshe Nceda usithumele i-imeyile: -info@hasungmachinery.com

Ixesha lokuposa: Jun-30-2022